Oil-resistant, cold-resistant, high-flame-retardant, low-smoke, halogen-free cable material and preparation method thereof

A kind of cable material, high flame retardant technology, applied in the field of halogen-free flame retardant cable material and its preparation, can solve the problems of low temperature resistance and mechanical properties, not being well solved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The method for preparing the cable can adopt conventional techniques in this field.

[0055] Preparation

[0056] The third aspect of the present invention provides a method for preparing the oil-resistant, cold-resistant, high-flame retardant, low-smoke, and halogen-free cable material of the present invention. The preparation method includes the following steps:

[0057] Mix the low VA content ethylene-vinyl acetate copolymer (EVA), the high VA content ethylene-vinyl acetate copolymer (EVA), the compatibilizer, and the processing aid according to the stated ratio for 4 to 5 minutes, and discharge and place; The flame retardant, antioxidant, and lubricant are mixed according to the stated ratio for 8-10 minutes, and the material is discharged and placed; then the two parts of the mixed material and the coupling agent are extruded and granulated according to the ratio. The oil-resistant, cold-resistant, high-flame retardant, low-smoke, halogen-free cable material is obtained....

Embodiment 1

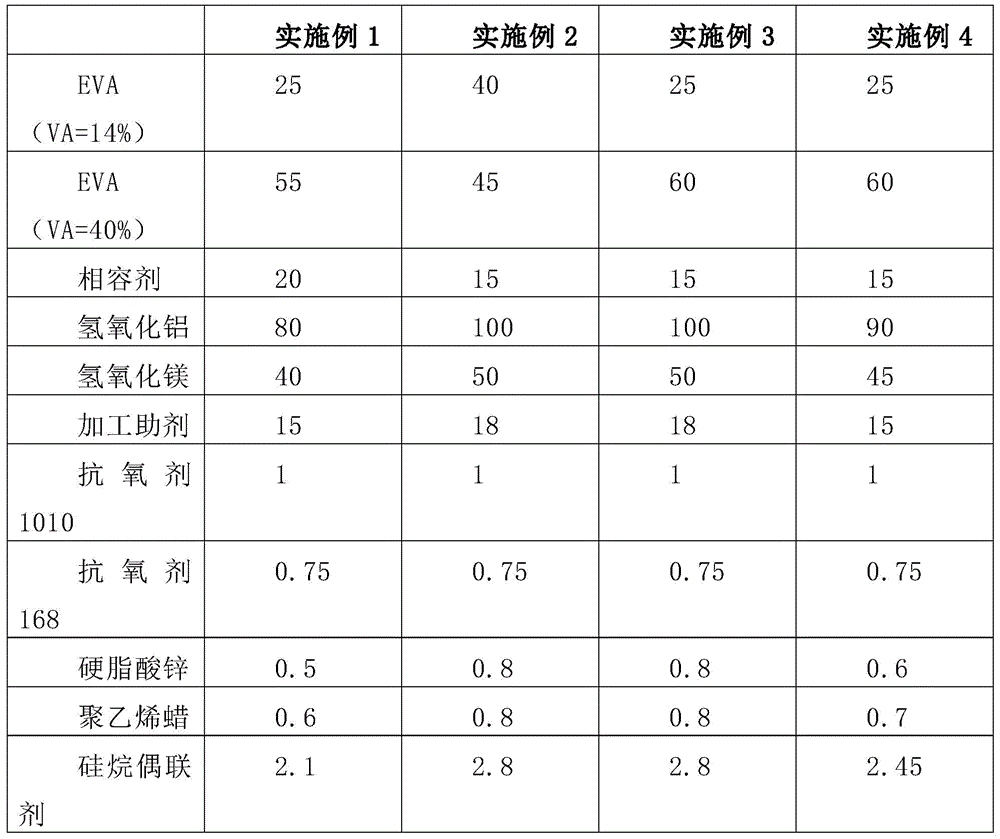

[0068] Table 1. Specific Examples

[0069]

[0070] The preparation method of the above invention includes the following process steps:

[0071] Mix ethylene-vinyl acetate copolymer (EVA) with VA content of 14%, ethylene-vinyl acetate copolymer (EVA) with VA content of 40%, compatibilizer, and processing aid according to the ratio in the examples for 4 to 5 minutes , Discharge and place; mix aluminum hydroxide, magnesium hydroxide, antioxidant 1010, antioxidant 168, zinc stearate, and polyethylene wax according to the ratio in the embodiment for 8-10 minutes, discharge and place; Part of the mixed material and silane coupling agent are extruded and granulated according to the ratio. The oil-resistant, cold-resistant, high-flame retardant, low-smoke, halogen-free cable material is obtained.

[0072] In addition, the temperature of each stage of the extruder starts from the feeding port and is 100~110℃, 110~115℃, 115~120℃, 120~125℃, 125~130℃, 130~135℃, 135~140℃ in sequence. , The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com