A kind of high-performance hydrogenated nitrile rubber compound and preparation method thereof

A high-performance technology of hydrogenated nitrile rubber, which is applied in the field of high-performance hydrogenated nitrile rubber compound and its preparation, and can solve problems such as unsatisfactory compression set, imperfection, and demanding performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

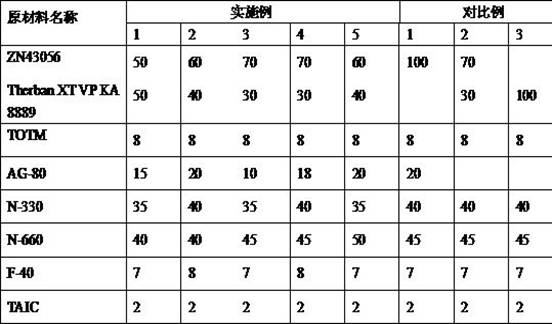

[0023] According to the formulations of Examples 1 to 5 in Table 1, firstly put the raw rubber of hydrogenated nitrile rubber (ZN43056) and carboxyl hydrogenated nitrile rubber (Therban XT VP KA 8889) into an internal mixer for mixing for 3 to 5 minutes, and then add 70 ~90 parts of carbon black, 8 parts of plasticizer (TOTM), and 10 to 20 parts of multifunctional epoxy resin (AG-80) are added to the internal mixer and mixed for 6 to 10 minutes to fully disperse in the rubber. In the matrix, organic peroxide and co-vulcanizing agent are added to the above masterbatch on an open mill and kneaded into a mixed rubber; the sample is vulcanized under the conditions of 180 ℃ × 20 minutes and 15 MPa with an electric heating plate vulcanizer.

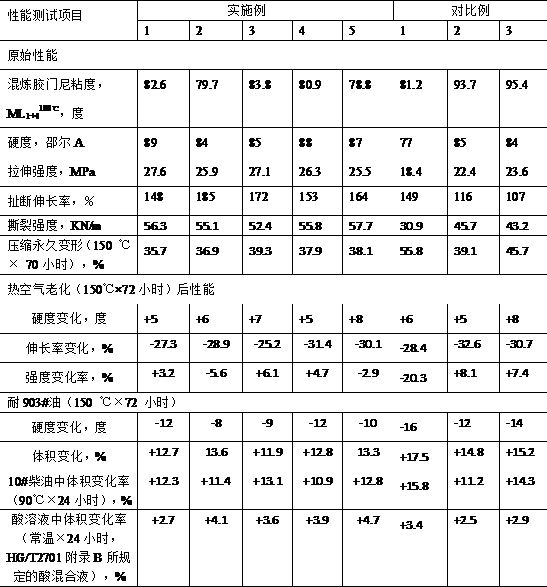

[0024] Test the Mooney viscosity of the mixed rubber according to the standard GB / T 1232.1-2000; test the hardness of the obtained vulcanized rubber sample according to the standard GB / T531.1-2008; test the tensile strength of the obtained vulca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com