Online prediction method of replacement rate and gold mud grade in hydro-metallurgy and replacement processes of gold

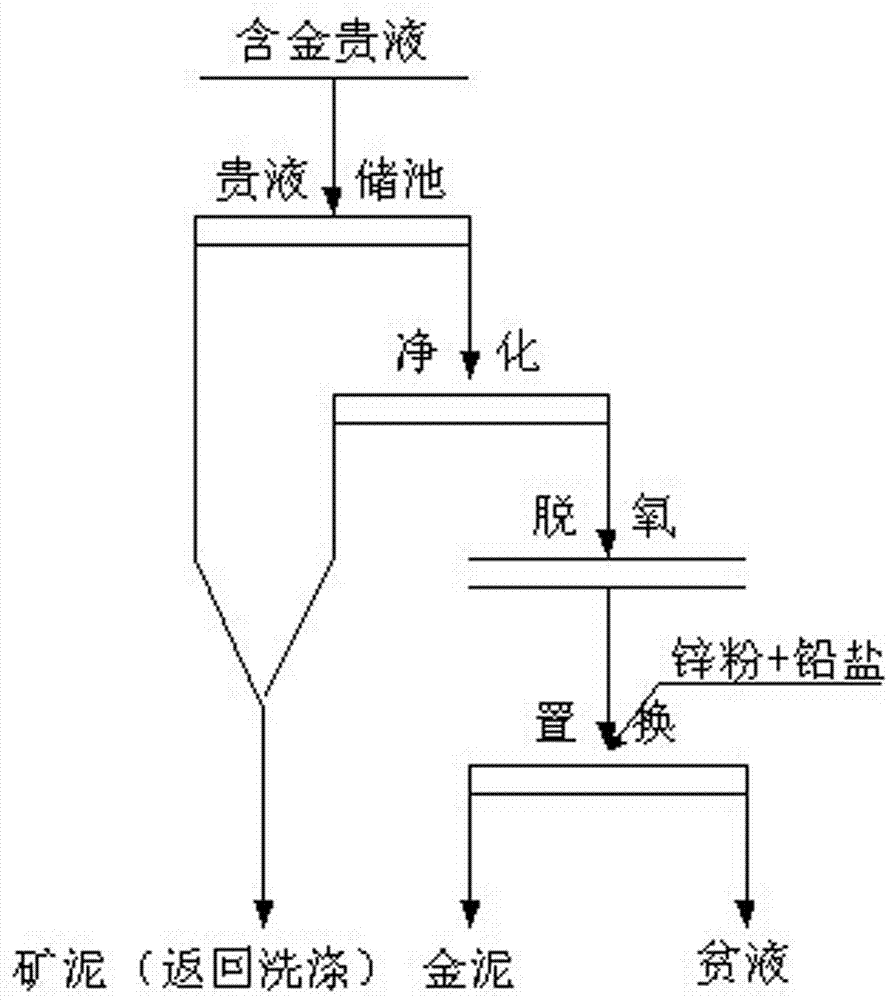

A replacement process and hydrometallurgy technology, which is used in the prediction of key technical indicators of the hydrometallurgical replacement process, real-time online prediction of replacement rate and gold mud grade, and can solve problems such as difficult maintenance, inability to fully meet the needs of continuous online inspection, and imperfect functions. problems, to ensure the quality and output, timely and accurate detection of production conditions, and improve the recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0173] Implementation on a hydrometallurgical high-grade displacement line.

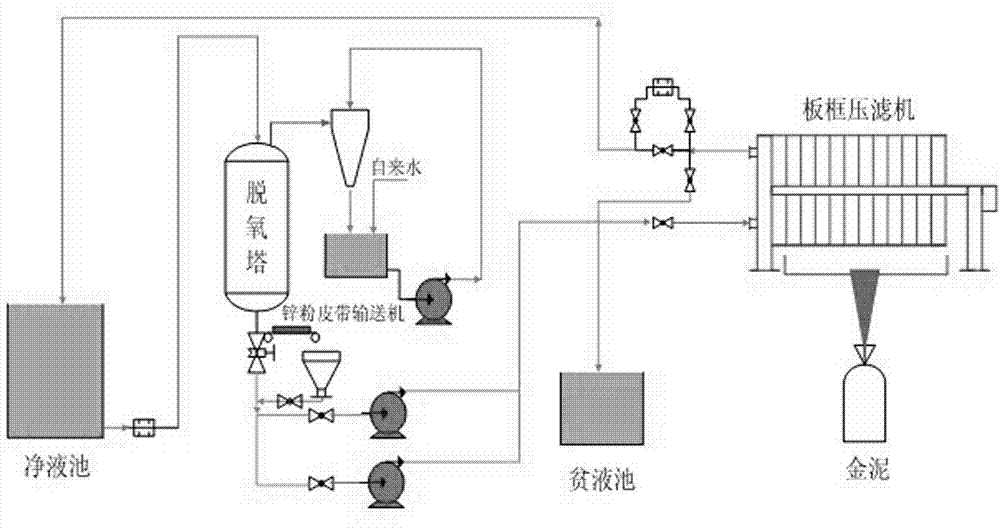

[0174] The production line has a water purification tank, a deoxidation tower, a jet vacuum pump, a jet vacuum system, a pool, 2 horizontal chemical pumps, a zinc powder feeding belt conveyor, and a zinc powder mixing Device, 1 hydraulic plate and frame filter press, 1 high-copper barren liquid pool, 1 electromagnetic flowmeter, such as figure 2 shown. The replacement process detection system is mainly composed of flow detection.

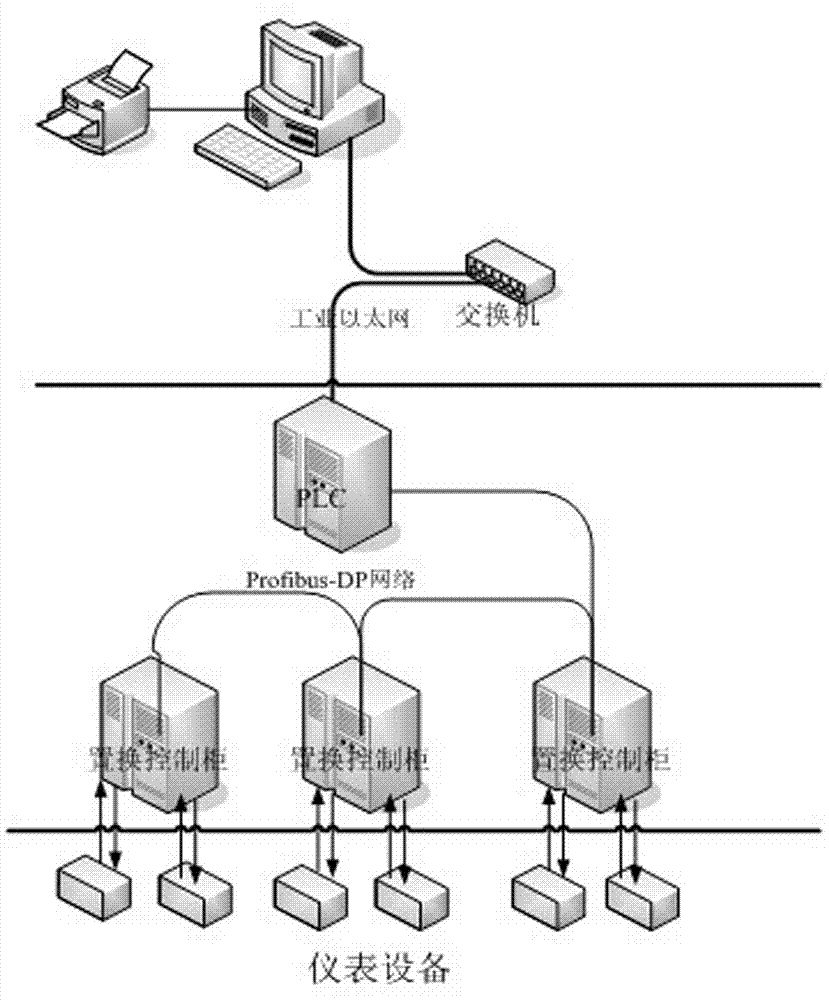

[0175] The PLC controller adopts CPU 414-2 of SIMATIC S7-40 series, which has PROFIBUS-DP port to connect distributed IO. Equip the PLC with an Ethernet communication module for the host computer to access PLC data. The PLC controller and Ethernet communication module are placed in the PLC cabinet in the central control room.

[0176] Since the material liquid, acid liquid and alkali liquid are all conductive and corrosive, the electromagnetic flowmeter with polytetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com