Production method of ultra-low carbon interstitial-free mild steel

A technology with no interstitial atoms and a production method, which is applied in the production field of ultra-low carbon interstitial atom-free mild steel, can solve the problems of increased difficulty in continuous casting, difficulty in carbon control, and large performance fluctuations, and achieves improved formability and improved production The effect of excellent process and finished product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The production method of the ultra-low carbon interstitial-free mild steel adopts the following specific processes.

[0022] (1) Hot metal pretreatment: remove the sulfur content in the hot metal to below 30ppm.

[0023] (2) Converter steelmaking process: 150 tons of converter steelmaking is used; end point temperature: 1710°C, end point oxygen level: 680ppm, Al-Ca slag material is added during the tapping process, and alloy material is not added.

[0024] (3) RH refining process: RH vacuum treatment for decarburization, adding an appropriate amount of Ti to fix C and N atoms in the steel, and Si alloying; the final deoxidation position is 260ppm, using Al for final deoxidation, after 3 minutes of final deoxidation Add ferro-titanium and appropriate amount of ferrosilicon, and pressurize again after 6 minutes of static circulation.

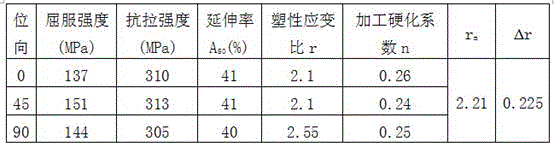

[0025] (4) Continuous casting process: medium slab continuous casting is adopted, heated by a walking heating furnace, the ...

Embodiment 2

[0032] Embodiment 2: The production method of the ultra-low carbon interstitial-free mild steel adopts the following specific processes.

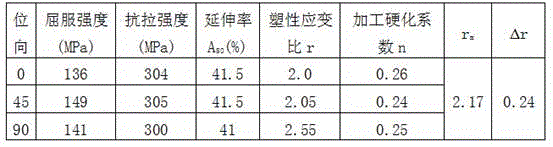

[0033] A 150-ton converter is used for steelmaking, molten iron with a sulfur content of less than 30ppm, the end point temperature of the converter: 1720°C, and the end point oxygen level: 800ppm. RH vacuum treatment for decarburization, adding an appropriate amount of Ti, and performing Si alloying; the final deoxidation position is 200ppm, using Al for final deoxidation, adding ferrotitanium after 4 minutes of final deoxidation, and adding an appropriate amount of ferrosilicon, and repressing after 5 minutes of static circulation . Medium slab continuous casting, heating by walking furnace, slab soaking section heating temperature is 1220°C, total heating time is 90 minutes; casting slab composition for hot rolling is (wt): C0.005% , Mn0.15%, S0.010%, P0.020%, Si0.15%, Ti0.070%, N50ppm, Als0.050%, Ca13ppm. The hot rolling adopts front ...

Embodiment 3

[0036] Embodiment 3: The production method of the ultra-low carbon interstitial-free mild steel adopts the following specific processes.

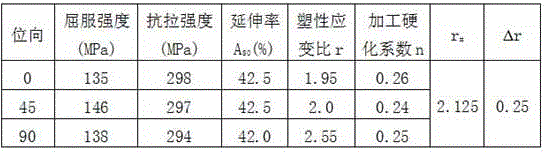

[0037]A 150-ton converter is used for steelmaking, molten iron with a sulfur content below 30ppm, the end point temperature of the converter: 1700°C, and the end point oxygen level: 620ppm. RH vacuum treatment for decarburization, adding an appropriate amount of Ti, and performing Si alloying; the final deoxidation position is 300ppm, using Al for final deoxidation, adding ferrotitanium after 3.5 minutes of final deoxidation, and adding an appropriate amount of ferrosilicon, and repressing after 7 minutes of static circulation . Medium slab continuous casting, heating by walking furnace, slab soaking section heating temperature is 1200°C, total heating time is 160 minutes; casting slab composition for hot rolling is (wt): C0.003% , Mn0.12%, S0.006%, P0.014%, Si0.10%, Ti0.064%, N28ppm, Als0.020%, Ca25ppm. Hot rolling adopts pre-cooling, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com