Light alkane dehydrogenation catalyst and preparation method

A technology of low-carbon alkanes and catalysts, which is applied in the field of catalysts and preparations of low-carbon alkanes dehydrogenation catalysts, which can solve the problems of slow deactivation rate of catalyst carbon deposition, insufficient mechanical strength of catalysts, and poor stability of catalysts, so as to improve catalytic activity and stability, preventing aggregation, and stabilizing catalyst performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

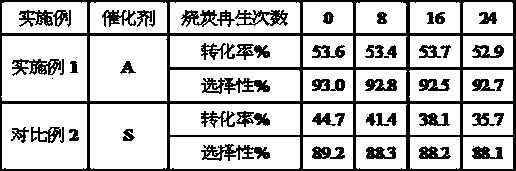

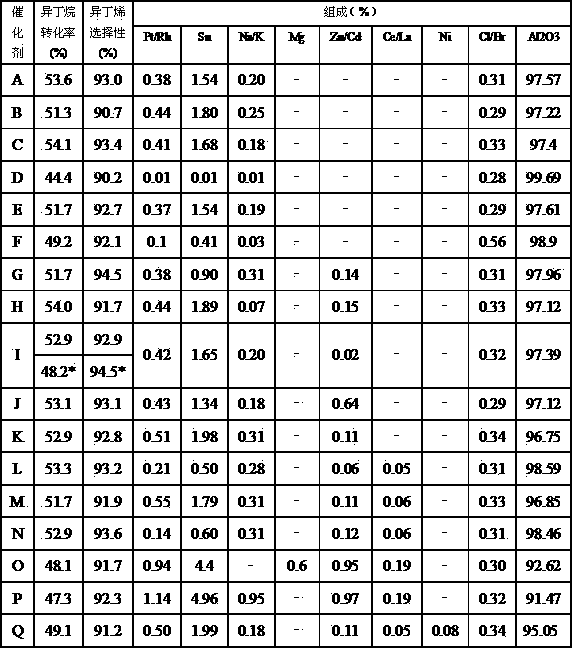

Embodiment 1

[0035] Add 99.3g of pseudo-boehmite raw powder with an average particle size of 10μm to 300.7g of pseudo-boehmite raw powder with an average particle size of 70μm, and then add 12.1g of safflower powder and 150ml of deionized water for kneading Fully extruded strips, placed at room temperature for 12 hours and then dried, the drying conditions are: first at 90°C for 3 hours, then at 120°C for 10 hours, after drying, cut into pellets and roast at 750°C for 4 hours. carrier. The resulting support strength was 203 N / cm.

[0036] Use impregnation technology to load the additive components, that is, use the obtained alumina carrier to impregnate the required amount of additive aqueous solution for 24 hours at room temperature, including 3.42g of sodium nitrate, dry it, and bake it at 600°C for 6 hours. Composite carrier containing catalytic promoters. Continue to use the impregnation technique to load the platinum tin component (2.13g platinum nitrate; 11.06g mixed aqueous soluti...

Embodiment 2

[0039] Add 240.0g of pseudo-boehmite raw powder with an average particle size of 10μm to 160.4g of pseudo-boehmite raw powder with an average particle size of 90μm, and then add 12.1g of scallop powder and 150 ml of deionized water for kneading Extrude strips fully, place at room temperature for 12 hours, and then dry. The drying conditions are: firstly at 90°C for 3 hours, then at 120°C for 10 hours, after drying, cut into pellets and roast at 650°C for 3 hours. carrier. The carrier strength was 254 N / cm.

[0040] Carry on cocatalyst (4.37g sodium nitrate) and platinum-tin component (2.37g platinum nitrate; 12.96g the mixed aqueous solution of stannous sulfate) respectively with the catalyst preparation method of embodiment 1 to obtain catalyst sample, denoted as B. The evaluation results are shown in Table 1.

[0041]

Embodiment 3

[0043] Add 141.1g of pseudo-boehmite raw powder with an average particle size of 20μm to 358.4g of pseudo-boehmite raw powder with an average particle size of 70μm, and then add 12.1g of safflower powder and 150 ml of deionized water for kneading Extrude strips fully, place at room temperature for 10 hours and then dry. The drying conditions are as follows: first at 90°C for 4 hours, then at 120°C for 9 hours, after drying, cut into pellets and roast at 700°C for 5 hours. carrier. The carrier strength was 167 N / cm.

[0044] Carry on cocatalyst (3.13g sodium nitrate) and platinum-tin component (2.24g platinum nitrate; 12.08g mixed aqueous solution of stannous sulfate) separately with the catalyst preparation method of Example 1 to obtain catalyst samples, denoted as C. The evaluation results are shown in Table 1.

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com