Method for preparing fenofibrate by virtue of intelligent temperature control and remote monitoring

A remote monitoring and fenofibrate technology, which is applied in the field of remote monitoring and preparation of fenofibrate and intelligent temperature control, can solve the problems of the three wastes not being effectively treated, the difficulty of industrialization implementation, and the large amount of acid and alkali. Large-scale industrial production, less impurities and less acid-base dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

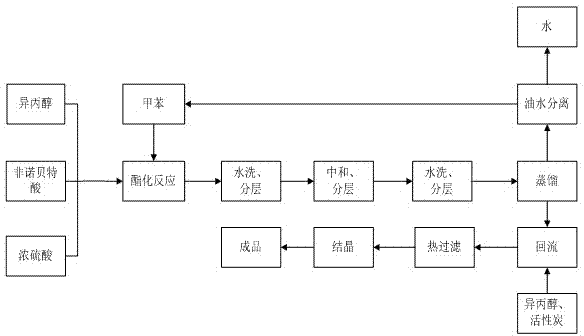

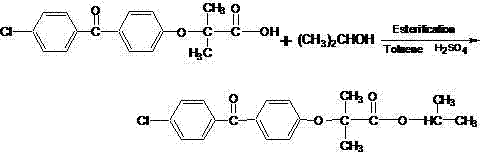

Method used

Image

Examples

Embodiment 1

[0018] Embodiment one: prepare a four-necked flask, two ports of this four-necked flask are provided with electric stirring bar, thermometer respectively, the 3rd port is provided with reflux condenser and water separator, and the 4th port is used for feeding; Add 60g of toluene, 18g of isopropanol, and 6g of concentrated sulfuric acid into the four-necked flask, then add 60g of fenofibric acid under stirring, and stir with an electric stirring bar, and the speed is controlled at 400r~500r / min. Heat to reflux at 110°C to separate the moisture generated by the reaction from the water separator. Toluene, a small amount of water and isopropanol flow back to the four-necked flask through the reflux condenser. When the reaction reaches anhydrous and then enters the water separator, stop heating and Stir, wash the feed liquid left after the esterification reaction with hot water at 60-70°C, separate the impurities and the feed liquid, keep the mixture of the upper layer of material a...

Embodiment 2

[0019] Embodiment two: prepare a four-necked flask, two ports of this four-necked flask are provided with electric stirring bar, thermometer respectively, the 3rd port is provided with reflux condenser and water separator, and the 4th port is used for feeding; Add 72g of toluene, 24g of isopropanol, and 8g of concentrated sulfuric acid into the four-necked flask, then add 60g of fenofibric acid under stirring, and stir with an electric stirring rod, and the speed is controlled at 400r~500r / min. Heat to reflux at 110°C to separate the moisture generated by the reaction from the water separator. Toluene, a small amount of water and isopropanol flow back to the four-necked flask through the reflux condenser. When the reaction reaches anhydrous and then enters the water separator, stop heating and Stir, wash the feed liquid left after the esterification reaction with hot water at 60-70°C, separate the impurities and the feed liquid, keep the mixture of the upper layer of material a...

Embodiment 3

[0020] Embodiment three: prepare a four-necked flask, two ports of this four-necked flask are provided with electric stirring bar, thermometer respectively, the 3rd port is provided with reflux condenser and water separator, and the 4th port is used for feeding; Add 84g of toluene, 30g of isopropanol, and 9g of concentrated sulfuric acid into the four-necked flask, then add 60g of fenofibric acid under stirring, and stir with an electric stirring rod, and the speed is controlled at 400r~500r / min. Heat to reflux at 110°C to separate the moisture generated by the reaction from the water separator. Toluene, a small amount of water and isopropanol flow back to the four-necked flask through the reflux condenser. When the reaction reaches anhydrous and then enters the water separator, stop heating and Stir, wash the feed liquid left after the esterification reaction with hot water at 60-70°C, separate the impurities and the feed liquid, keep the mixture of the upper layer of material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com