Polyphenyl ether/polypropylene copolymer blended alloy material and preparation method thereof

A technology of polypropylene copolymer and polyphenylene ether, which is applied in the field of polyphenylene ether/polypropylene copolymer (PPO/PP) blend alloy material and its preparation, can solve the problem of poor compatibility of PPO/PP alloy and PPO solvent resistance In order to improve compatibility, improve solvent resistance and impact resistance, and improve surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

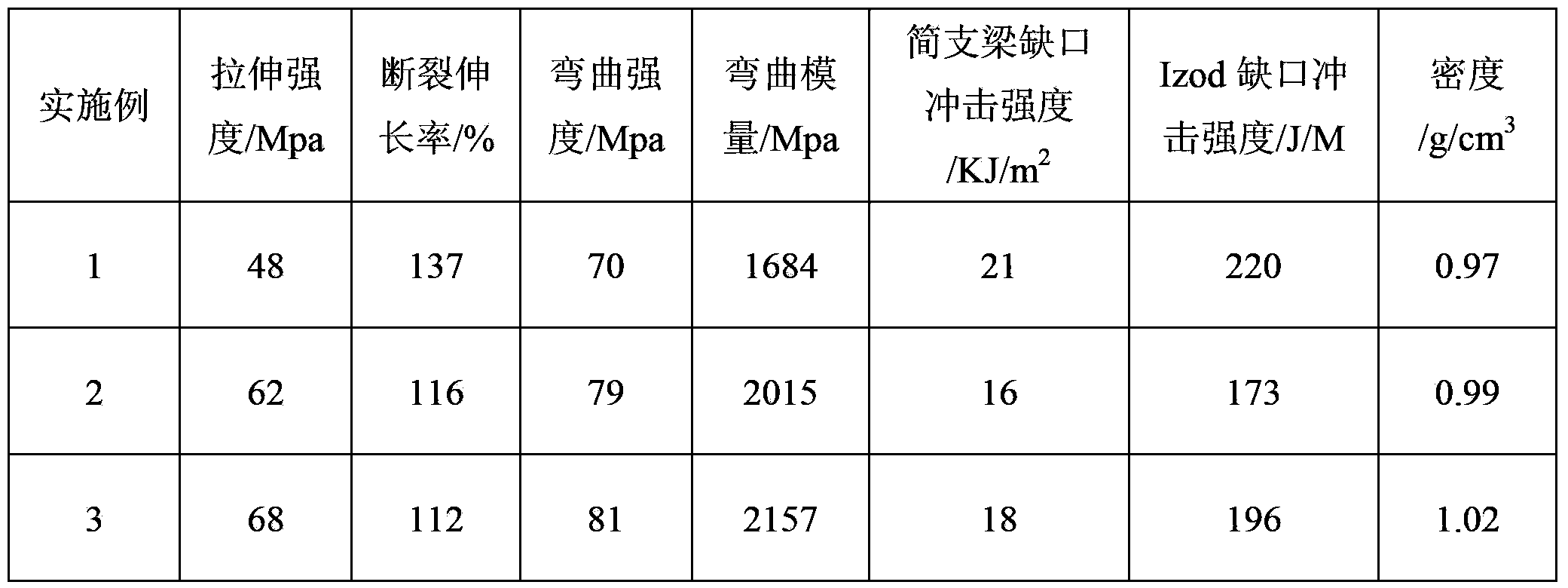

Embodiment 1

[0029] (1) Weigh the raw materials of each component according to the following parts by weight:

[0030] 25 parts of polyphenylene ether,

[0031] 55 parts of isotactic polypropylene,

[0032] 5 parts of compatibilizer PP-g-MAH,

[0033] Toughener SEPS 15

[0034] Antioxidant 1010 0.1 part,

[0035] Antioxidant 168 0.2 parts,

[0036] 0.2 parts of calcium stearate;

[0037] Among them, polyphenylene ether is polyphenylene ether pretreated by maleic anhydride (the mass ratio of polyphenylene ether to maleic anhydride is 100:1), and the extrusion temperature is 270-280°C.

[0038] Mix the above raw materials at a high speed with a high-speed mixer, the speed of the high-mixer is 800-1000rmp, the mixing temperature is 30°C, and mix for 10 minutes;

[0039] (2) Pass the mixed material through a twin-screw extruder, control the temperature of each zone at 230-260°C, and cut the strands into pellets to obtain the product.

Embodiment 2

[0041] (1) Weigh the raw materials of each component according to the following parts by weight:

[0042] 40 parts of polyphenylene ether,

[0043] 45 parts of isotactic polypropylene,

[0044] 8 parts of compatibilizer PP-g-GMA,

[0045] Toughener SEBS-g-MAH 5 parts,

[0046] Antioxidant 1010 0.2 parts,

[0047] Antioxidant 168 0.4 parts,

[0048] Silicone 0.5 parts;

[0049] Among them, polyphenylene ether is polyphenylene ether pretreated by maleic anhydride (the mass ratio of polyphenylene ether to maleic anhydride is 100:3), and the extrusion temperature is 280-290°C.

[0050] Mix the above raw materials at a high speed with a high-speed mixer, control the speed of the high-mixer to 800-1000rmp, the mixing temperature is 60°C, and mix for 3 minutes;

[0051] (2) Pass the mixed material through a twin-screw extruder, the temperature of each zone is controlled at 250-280°C, and the extruder strands are cut into pellets to obtain the product.

Embodiment 3

[0053] (1) Weigh the raw materials of each component according to the following parts by weight:

[0054] 50 parts of polyphenylene ether,

[0055] 27 parts of isotactic polypropylene,

[0056] 3 parts of compatibilizer SMA,

[0057] 10 parts of compatibilizer PP-g-MAH,

[0058] 10 parts of toughening agent SEBS,

[0059] Antioxidant 1010 0.2 parts,

[0060] Antioxidant 168 0.3 parts,

[0061] Zinc stearate 0.5 parts;

[0062] Among them, polyphenylene ether is polyphenylene ether pretreated by maleic anhydride (the mass ratio of polyphenylene ether to maleic anhydride is 100:2), and the extrusion temperature is 270-280°C.

[0063] The above raw materials are mixed at high speed by a high-speed mixer, the speed of the high-mixer is 800-1000rmp, the mixing temperature is 60°C, and the mixing is 6 minutes;

[0064] (2) Pass the mixed material through the twin-screw extruder, the temperature of each zone is controlled at 250-280°C, and the product can be obtained by cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com