High-hot-strength spray-formed hot work die steel and preparation method thereof

A hot work die steel and spray forming technology, which is applied in the fields of high thermal strength spray forming hot work die steel new material, subsequent hot working and heat treatment, and spray forming preparation fields, can solve the problems of insufficient use of spray forming and coarse structure, etc. Achieve good thermal stability and tempering resistance, high impact toughness, and improve the effect of hot work die life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The high thermal strength hot work die steel of the present invention realizes high performance by optimizing the compatibility of alloy components and adjusting the spray forming process. The preparation method is as follows: (1) Preparing hot-working die steel deposition blanks by spray forming technology: smelting in induction furnaces under vacuum or non-vacuum until the chemical composition range meets the requirements, keeping the temperature for 10-20min, and superheating the molten steel at 100-200°C , and then poured into a tundish with a temperature above 1000°C. The molten steel is atomized by N2. The atomization system adopts non-restricted primary and secondary two-stage annular hole atomization nozzles. The deposition distance is 400-500mm, and the deposition substrate is stainless steel. As the spray deposition process proceeds, the substrate is pulled down at a constant speed, and finally a columnar deposition blank with a diameter of 120 mm and a height...

Embodiment 2

[0043] The preparation method, thermal processing and heat treatment process of the inventive steel described in this example are the same as in Example 1, and the commercial H13 steel in Example 1 is still used as the comparison steel.

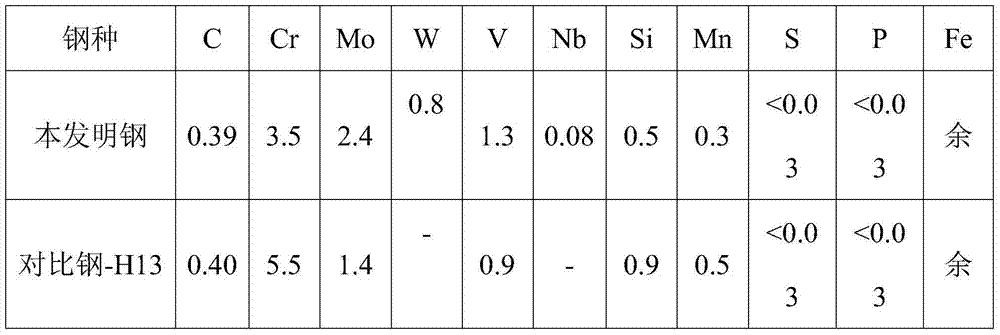

[0044] The chemical compositions of steel of the present invention and contrast steel are shown in Table 5

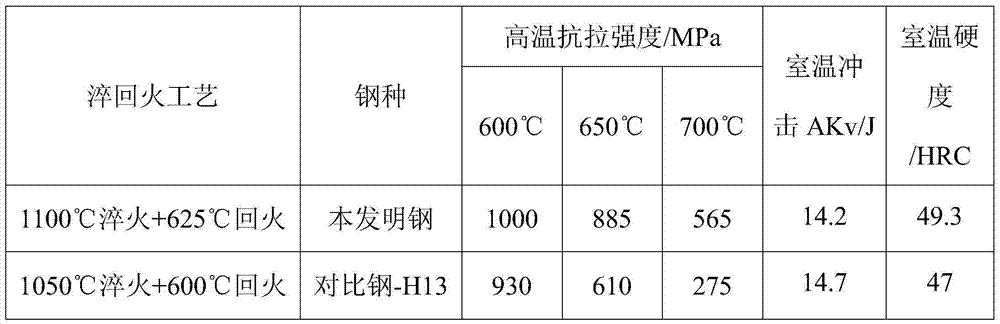

[0045] Under the condition that the hardness at room temperature is similar to that of the comparison steel, the high-temperature tensile performance of the steel of the invention is obviously better than that of the comparison steel, and the impact toughness is also higher than that of the comparison steel. The specific performance data comparison is shown in Table 6.

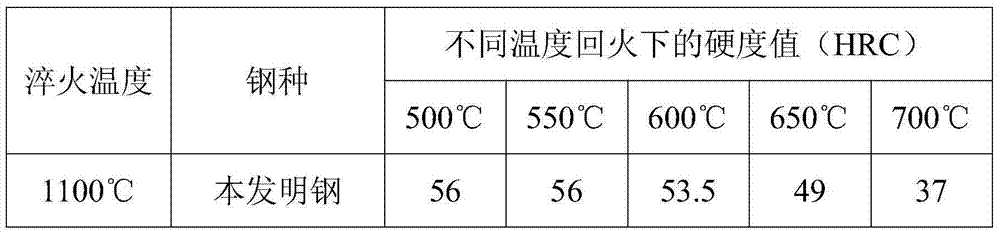

[0046] The temper resistance and thermal stability of the inventive steel are significantly better than those of the comparative steel. For specific performance data comparison, see Table 7 and Table 8.

[0047] Table 5: Chemical composition of steel of the present i...

Embodiment 3

[0056] The preparation method, thermal processing and heat treatment process of the inventive steel described in this example are the same as in Example 1, and the commercial H13 steel in Example 1 is still used as the comparison steel.

[0057] The chemical compositions of steel of the present invention and contrast steel are shown in Table 9

[0058] Under the condition that the hardness at room temperature is similar to that of the comparison steel, the high-temperature tensile performance of the steel of the invention is obviously better than that of the comparison steel, and the impact toughness is also higher than that of the comparison steel. The specific performance data comparison is shown in Table 10.

[0059] The temper resistance and thermal stability of the inventive steel are significantly better than those of the comparative steel. For specific performance data comparison, see Table 11 and Table 12.

[0060] Table 9: Chemical composition of steel of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com