Automation machine for batch-grinding various chemical test blocks

A technology of batch grinding and test pieces, applied in the preparation of test samples, etc., can solve the problems of not being able to fully guarantee the uniformity of each group of test pieces, hindering the improvement of work efficiency, and difficulty in achieving uniformity, etc., to achieve fast and efficient grinding , easy to operate, simple to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

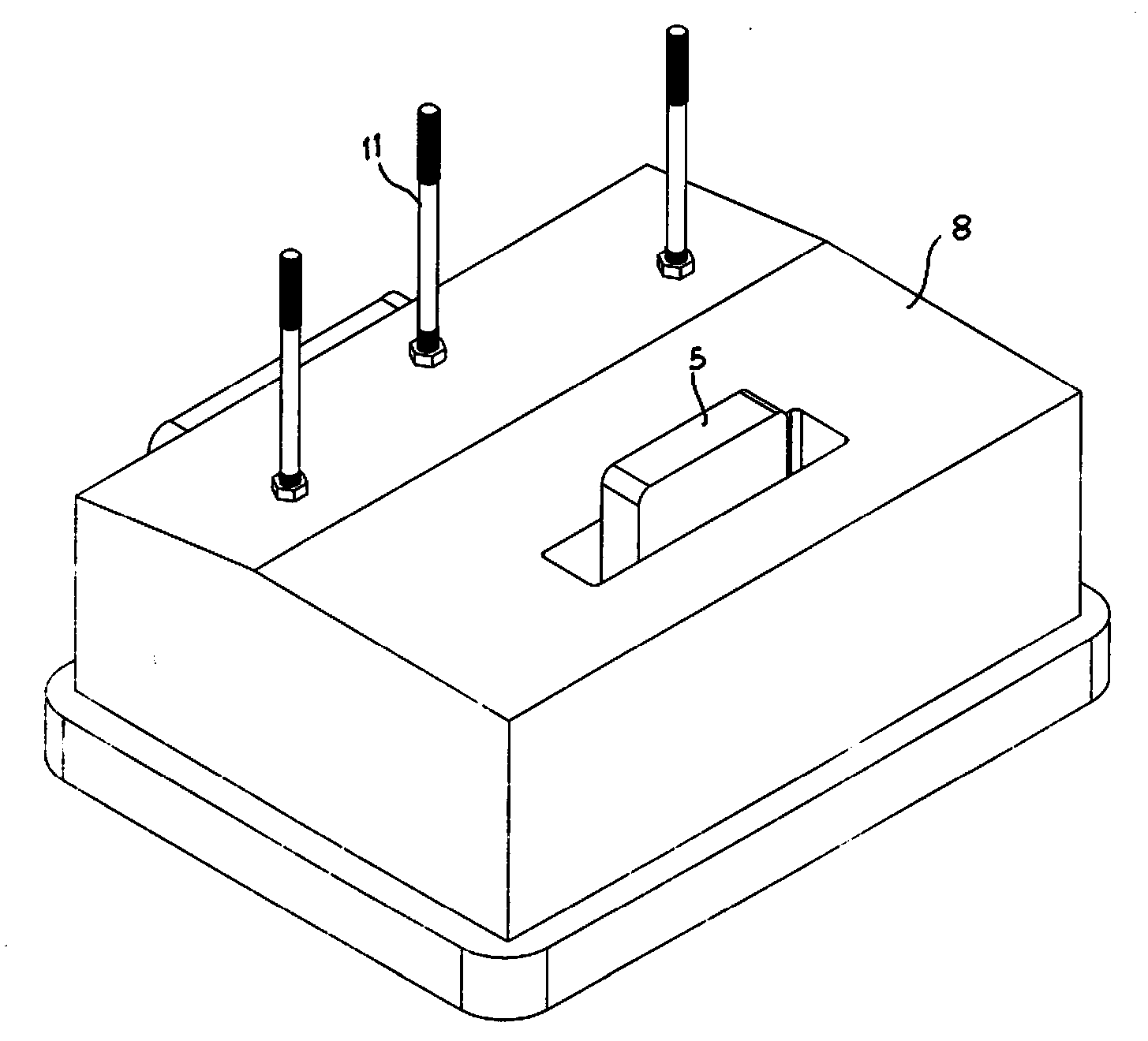

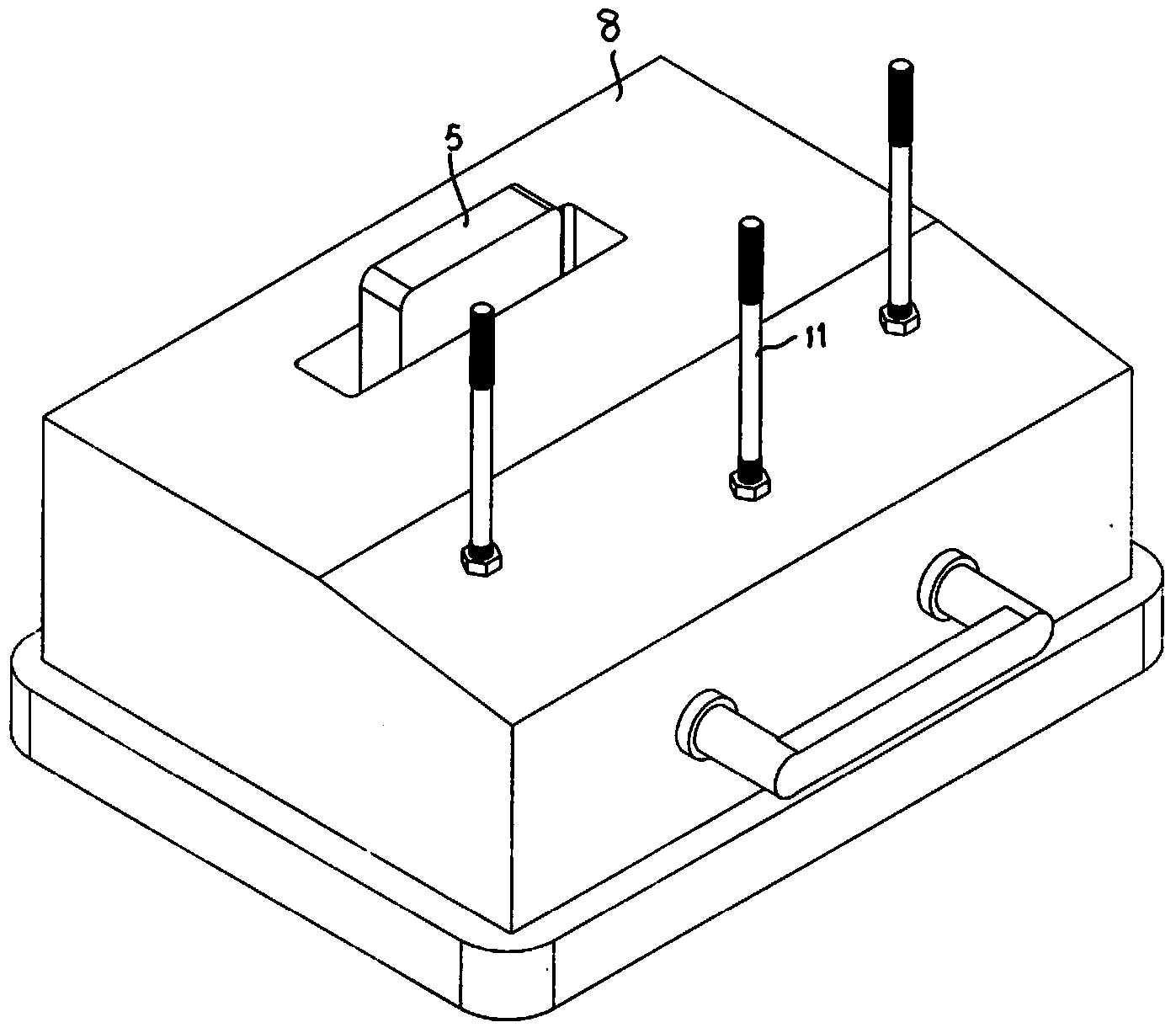

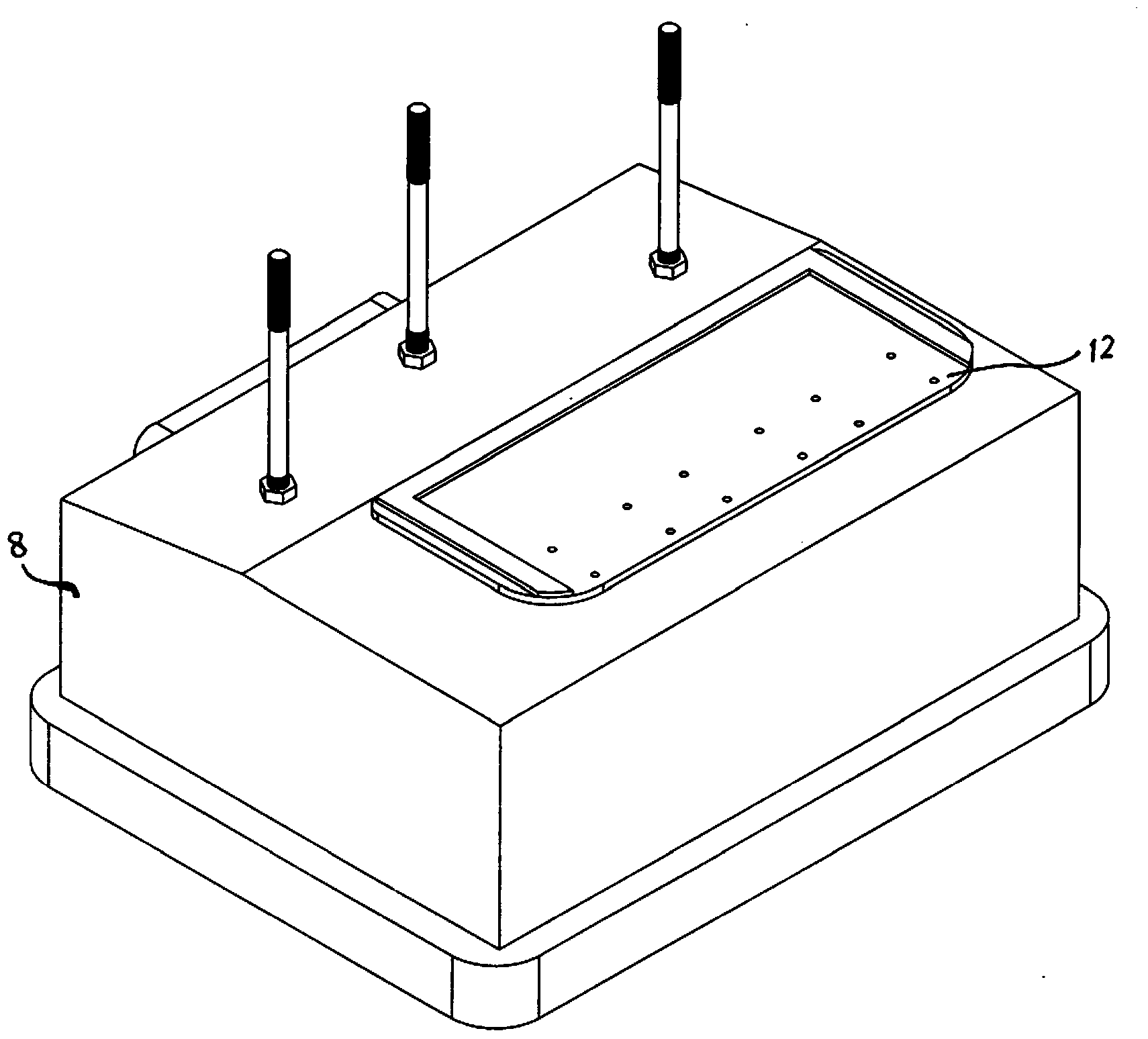

[0042] figure 1 , figure 2 , image 3 , Figure 3-1 , Figure 4 , Figure 5It shows an automatic machine for grinding various chemical test pieces in batches, including a motor start control device, and the horizontal reciprocating drive mechanism is: an eccentric wheel 4 is installed on the output shaft 3 of the geared motor, and an eccentric column 4a is fixed on the eccentric wheel 4 , the two guide rods 6 are installed on the U-shaped frame 7 in the horizontal direction, the translation block 5 is movably sleeved on the two guide rods 6, and the eccentric column 4a on the above-mentioned eccentric wheel is inserted into the bar of the translation block 5 with a gap. The above-mentioned horizontal reciprocating drive mechanism is installed in the casing 8, and the upper part of the translation block 5 protrudes from the hole on the top plate of the casing 8, and is used as a test piece tray for holding a plurality of chemical test pieces 13 12 is horizontally set on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com