Method for determination of carbon black content in process gas

A determination method and technology for carbon black content, applied in the field of coal chemical industry, can solve problems such as simple and accurate determination of carbon black content, and achieve the effects of small relative error, avoiding influence, and accurate carbon black content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

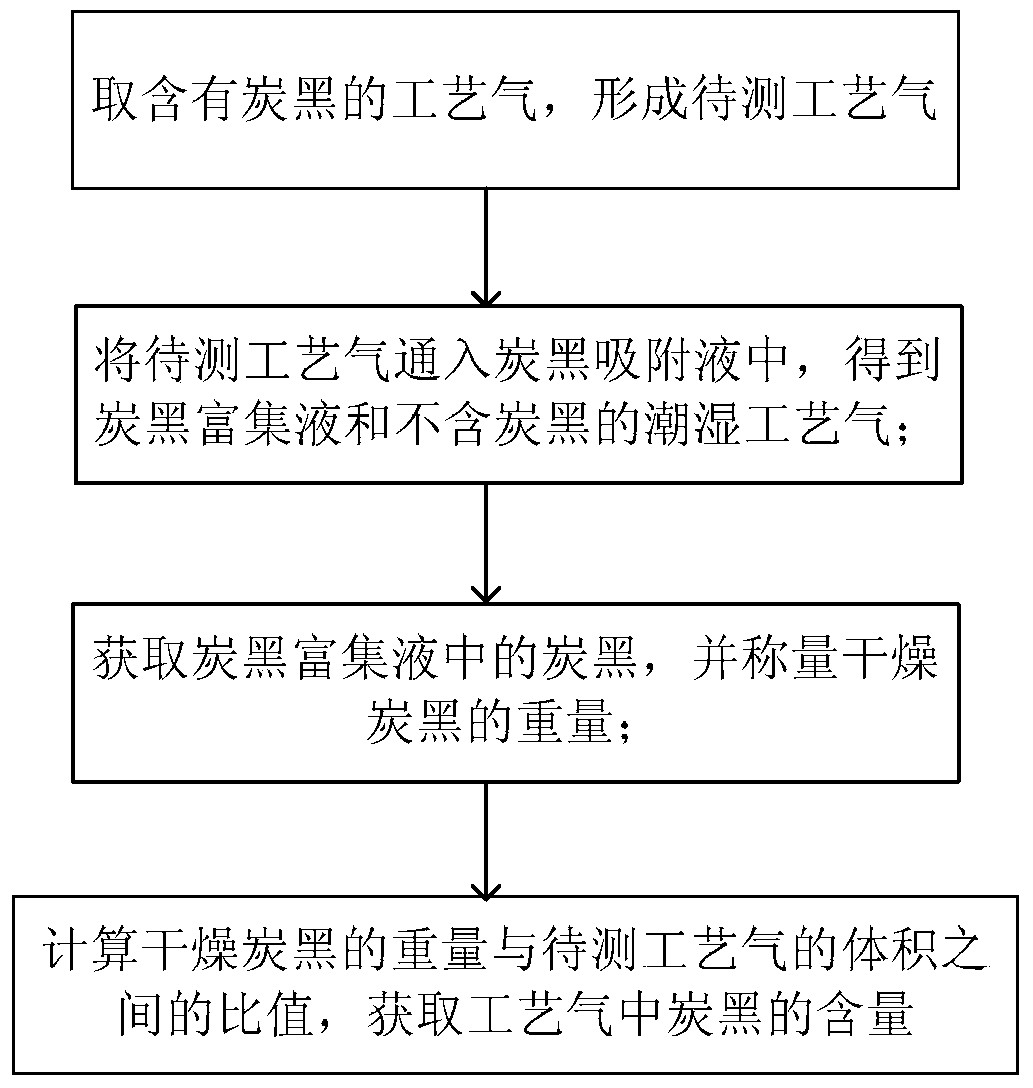

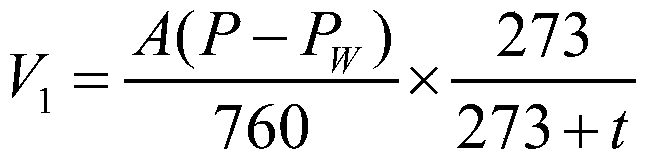

Method used

Image

Examples

Embodiment 1

[0077] 1. Preparation work:

[0078] (1) Take two absorption bottles with a volume of 250ml, put 100ml of high-purity water into the absorption bottle 1 and the absorption bottle 2 respectively, after weighing, it will be C1, insert the air intake pipe 1.5cm below the water surface, and put the absorption bottle and the air intake pipe The pipe is carried to the process gas site for sampling.

[0079] (2) Soak the acid-washed asbestos and filter paper with ultra-pure water in advance, and then put the Buchner funnel containing the acid-washed asbestos and filter paper into the oven, dry at 105°C for 3 hours, cool in the desiccator, and use an analytical balance to quickly Accurately weigh the mass a of the dry Buchner funnel (together with acid-washed asbestos and filter paper) before absorption.

[0080] (3) Fill 100 ml of NaOH solution with a mass concentration of 0.5% into the absorption bottle 3 with a volume of 250 nl, and carry it to the sampling site for standby.

[0...

Embodiment 2

[0093] 1. Preparation work:

[0094] (1) Take 4 absorbing bottles whose volume is 500ml, fill 200ml tap water in absorbing bottle 1, absorbing bottle 2, absorbing bottle 3 and absorbing bottle 4, and record the total mass of four absorbing bottles as C1 after weighing, Insert the intake pipe 2cm below the water surface, and carry the absorption bottle 1, absorption bottle 2, absorption bottle 3, absorption bottle 4 and the intake pipe to the process gas site for sampling.

[0095] (2) Soak the acid-washed asbestos and filter paper with tap water in advance, and then put the glass sand core funnel containing the acid-washed asbestos and filter paper into the oven, dry at 115°C for 3 hours, cool in the desiccator, and quickly and accurately use an analytical balance Weigh the mass a of the dry Buchner funnel (together with acid-washed asbestos and filter paper) before absorption.

[0096] (3) Fill 150 ml of NaOH solution with a mass concentration of 0.3% into the absorption bot...

Embodiment 3

[0109] 1. Preparation work:

[0110] (1) Fill 100ml of high-purity water into absorption bottle 1, absorption bottle 2 and absorption bottle 3 with a volume of 1000ml, record it as C1 after weighing, insert the air intake pipe 1.5cm below the water surface, and place absorption bottle 1, absorption bottle 2 , the absorption bottle 3 and the intake pipe are carried to the process gas site for sampling.

[0111] (2) Soak the acid-washed asbestos and filter paper with tap water in advance, and then put the glass sand core funnel containing the acid-washed asbestos and filter paper into the oven, dry at 110°C for 3 hours, cool in the desiccator, and quickly and accurately use an analytical balance Weigh the mass a of the dry Buchner funnel (together with acid-washed asbestos and filter paper) before absorption.

[0112] (3) Fill 200ml of NaOH solution with a mass concentration of 0.8% into the absorption bottle 4 with a volume of 1000ml, and carry it to the sampling site for stan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com