Method for manufacturing an embedded package and structure thereof

An encapsulation structure and encapsulation technology, which are applied in the manufacturing of electric solid-state devices, semiconductor devices, and semiconductor/solid-state devices, etc., can solve the problems of high technical thresholds and manufacturing costs, heat dissipation in complex testing processes, and 3DIC scrapping, etc., and achieve convenient assembly. , the effect of shortening process time and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 example

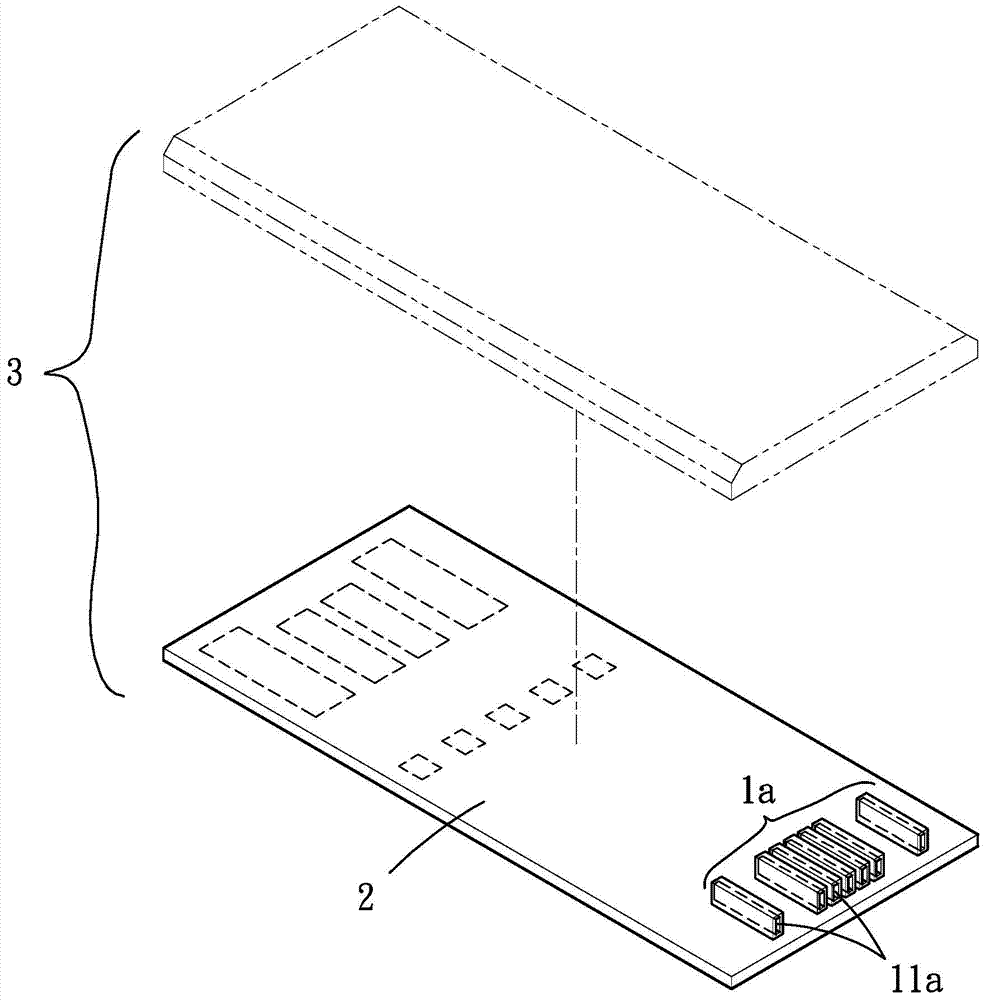

[0086] Another example Figure 10 Schematically, it is used to illustrate the third embodiment of the present invention, which is another LGA-packaged electronic carrier 5 made by implementing the first electronic carrier 5 in the LGA package in the second embodiment as described in the above-mentioned steps 1 and 2. The first electronic carrier 5a (that is, including at least a second embedded seat body 1c and a second circuit substrate 2c connected to each other, the second embedded seat body 1c has a plurality of connection ports 11c) is implemented; further In this embodiment, the stacked first electronic carrier 5a can be electrically connected to the connecting port 11c and the connecting port 11b by at least one connecting member 6, and the connecting member 6 can be an electric wire or conductive glue or use a circuit Plating lines of redistribution layer (RDL) technology;

[0087] In this way, after the package body 3b and the first electronic carrier 5a are stacked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com