Particles for Electrophoretic Displays

A particle and electrophoretic fluid technology, applied in the direction of instruments, transportation and packaging, optics, etc., to achieve the effect of good mobility and good bistability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment 1

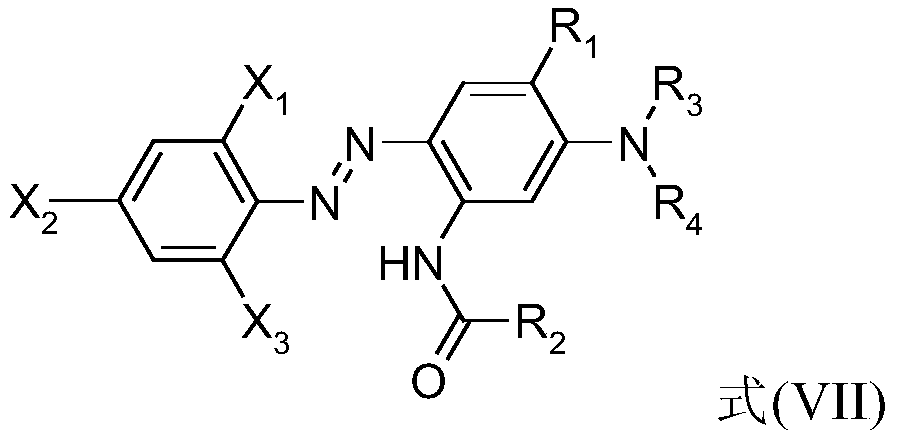

[0100] Example 1: (E)-4,4'-(4-((2,6-dicyano-4-nitrophenyl)diazenyl)-2-methoxy-5-(3,5,5- Trimethylcaproylamido)phenylazanediyl)bis(butan-4,1-diyl)diacrylate

[0101] (Dye 3)

[0102]

[0103] Step 1: 4,4'-(5-acetamido-2-methoxyphenylazanediyl)bis(butan-4,1-diyl)diacetate

[0104] 3'-amino-4'-methoxyacetanilide (18.0g, 0.1mol), 4-bromobutyl acetate (48.8g, 0.25mol), 1-methyl-2-pyrrolidone (50ml) and bicarbonate A stirred mixture of sodium (55.2g, 0.66mol) was heated in an oil bath at 105°C overnight, allowed to cool and then poured into water (500ml). After stirring for 30 minutes, the separated oil was extracted with dichloromethane (150ml), the organic layer was dried (MgSO 4 ) and evaporated to give a thick brown oil (57.0 g). The oil (95% purity) was used without further purification.

[0105] Step 2: 4,4'-(5-Amino-2-methoxyphenylazanediyl)dibutan-1-ol

[0106] Crude 4,4'-(5-acetamido-2-methoxyphenylazanediyl)bis(butan-4,1-diyl)diacetate (0.1 mol) was dissolved in...

Embodiment 2

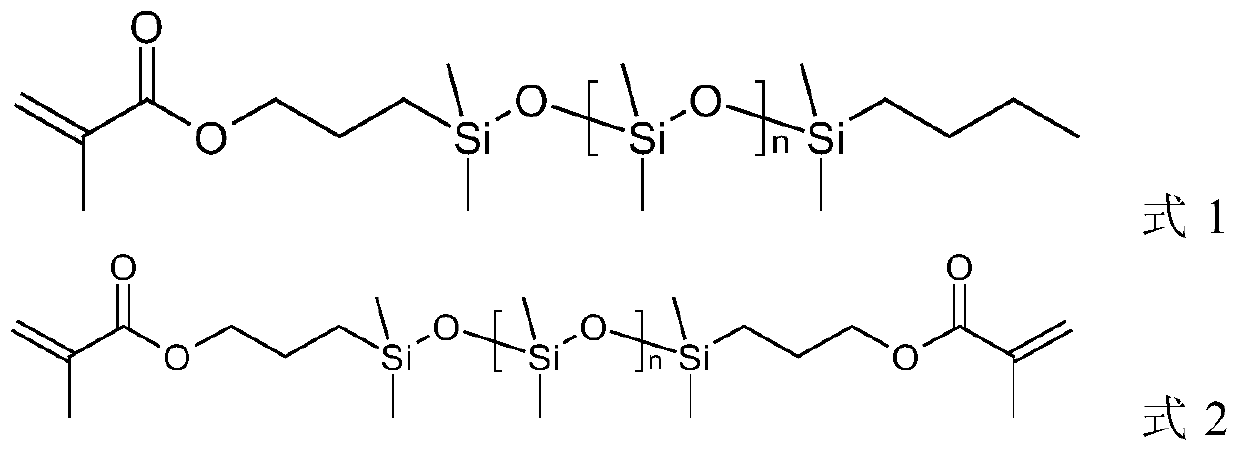

[0117] Example 2: Preparation of Cyan Polymer Particles Using Mono-Encapped PDMS Methacrylate Stabilizer

[0118] Monomethacrylate terminated polydimethylsiloxane of mw. 10,000 (1.70 g) was dissolved in dodecane (42 g) in a 100 ml three necked round bottom flask. Methyl methacrylate (5.4ml), cyan dye (Dye 3) (0.25g) and octyl thiol (0.13ml) were added. The flask was heated to 80 °C under nitrogen with stirring at 300 rpm. AIBN (0.11 g) was added. The mixture was stirred for 2 hours, and then cooled to room temperature and the contents were filtered through a 50 micron cloth. The cyan dispersion was cleaned by centrifugation and the supernatant was replaced with clean dodecane. The average particle size is 449 nm.

Embodiment 3

[0119] Example 3: Preparation of Magenta Polymer Particles Using Mono-Encapped PDMS Methacrylate Stabilizer

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com