Method for preparing and modifying titanium silicalite molecular sieve catalyst and application of titanium silicalite molecular sieve catalyst in ketone oximation

A technology of titanium-silicon molecular sieves and catalysts, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as complex operations, poor stability, and application limitations, and achieve simple preparation and modification operations, and high reaction Improved activity and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

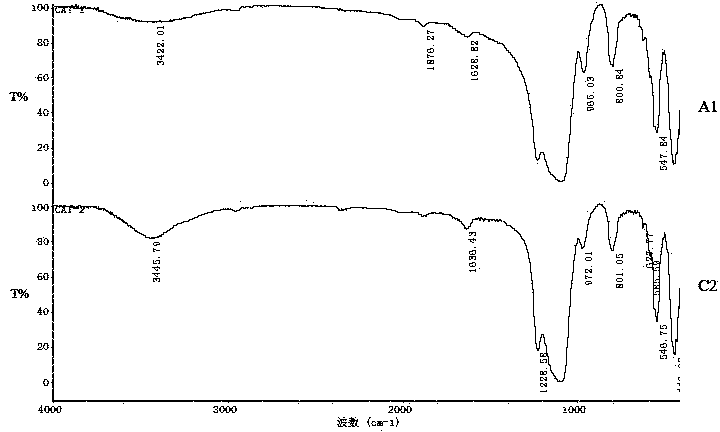

[0035] Weigh 1.0g molecular sieve A1 and add to 20mL 1M HCl solution and 2.5mL H 2 o 2 In the middle, stir at 60°C for 4h, cool to room temperature, wash to neutral, dry at 110°C for 3h, and calcinate at 550°C for 3h to obtain modified titanium-silicon molecular sieve B1.

Embodiment 2~4

[0037] The preparation process is the same as in Example 1, and the specific raw material ratio and acid treatment conditions are shown in Table 1, and the sample numbers of the obtained modified titanium-silicon molecular sieve catalysts are B2-B4.

Embodiment 5

[0039] Weigh 1.0g molecular sieve B1, 1.0g TPAOH, 0.0149g NH 4 HSO 4 , and 20g of water were added to the crystallization kettle, stirred and mixed evenly, crystallized at 175°C for 12h, cooled to room temperature, washed, dried, and calcined at 550°C for 4h to obtain modified titanium-silicon molecular sieve C1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com