High-efficiency environment-friendly desalted water production method

A production method and high-efficiency technology, applied in the field of water treatment, to achieve the effect of low power consumption, less operation and less maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

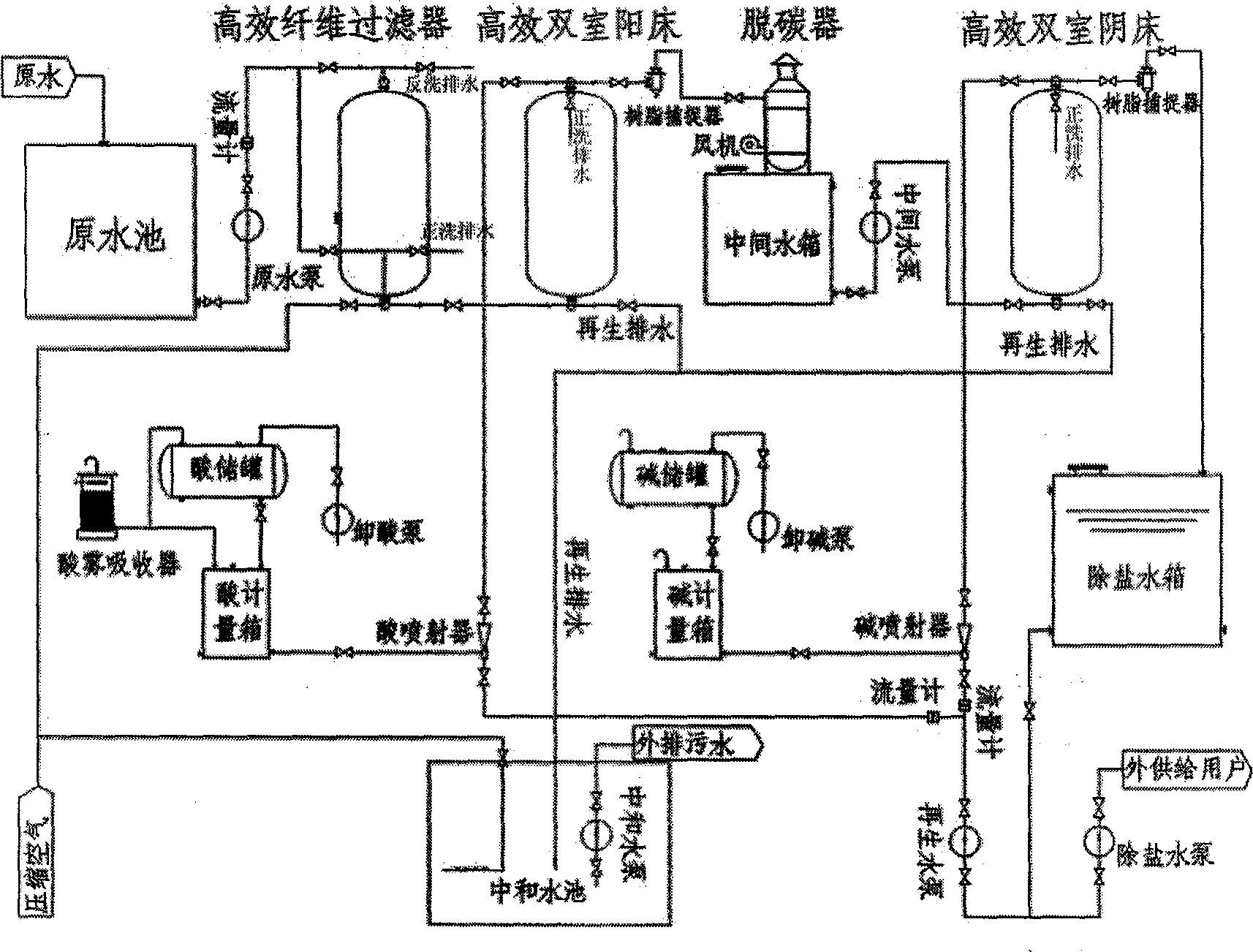

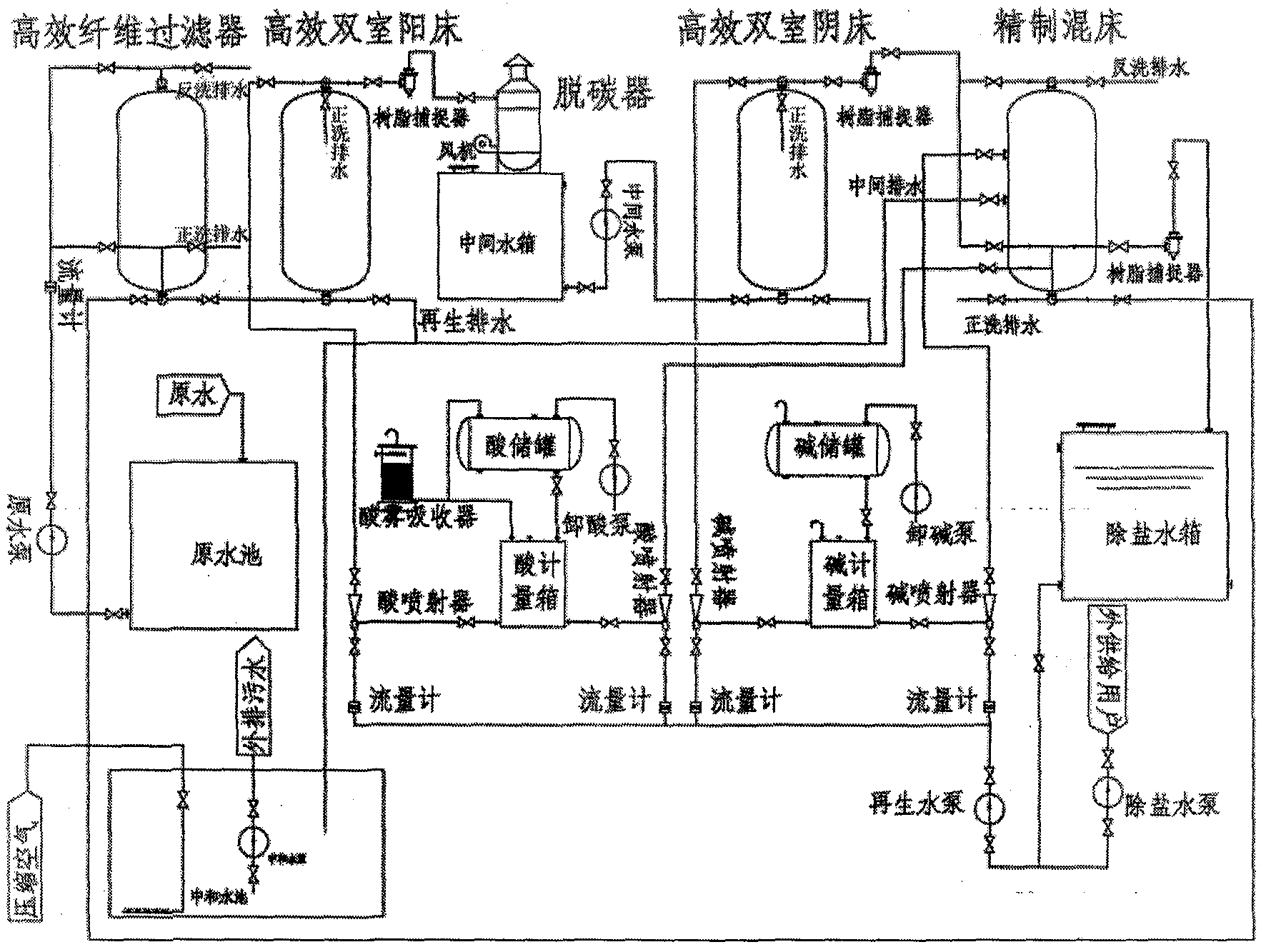

[0020] Such as figure 1 , figure 2As shown, a high-efficiency and environmentally friendly desalinated water production method includes sequentially connecting the raw water pool, the high-efficiency double-chamber positive bed, the decarburizer, the high-efficiency double-chamber negative bed, and the desalinated water tank through pipelines. There is a high-efficiency fiber filter on the connecting pipe between the decarburizers, and an intermediate water tank is installed at the lower part of the decarburizer. The water outlet at the top of the double-chamber yang bed is connected to the acid regeneration system, and the top water outlet of the high-efficiency double-chamber yin bed is connected to the alkali regeneration system. The pool discharges sewage through the neutralization pump, the compressed air machine is connected to the neutralization pool and the high-efficiency fiber filter through pipelines, the outlet of the desalinated water tank is connected to the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com