Composite ceramic dispersant and preparation method thereof

A composite ceramic and dispersant technology, applied in the field of ceramic additive manufacturing, can solve the problems that clay mineral raw materials cannot be used, the dispersant has no versatility, and the effect is not obvious, etc., to achieve appropriate viscosity, less addition, and good versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

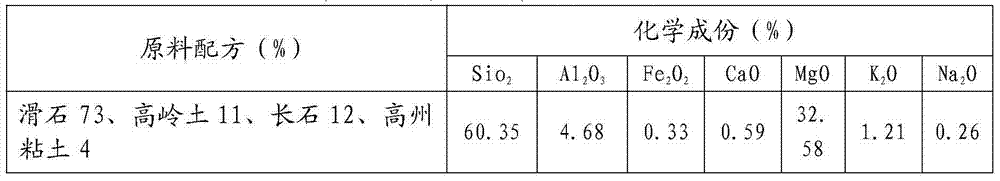

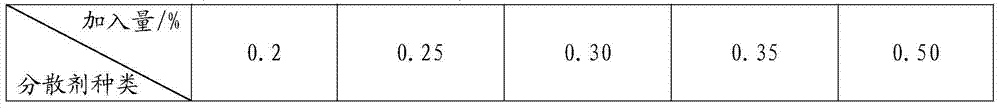

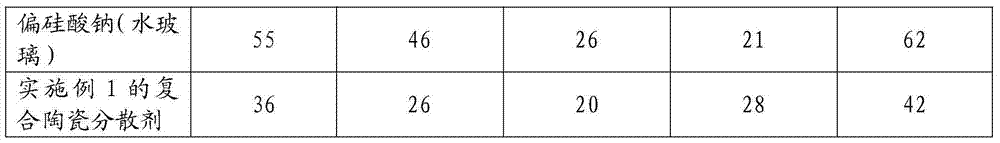

Method used

Image

Examples

Embodiment 1

[0020] A composite ceramic dispersant is composed of the following raw materials by weight percentage: 35% of sodium humate, 10% of polyacrylamide, 20% of sodium polyacrylate, 3.0% of potassium persulfate and 32% of water.

[0021] Its preparation method comprises the following steps:

[0022] First prepare raw materials according to the following weight percentages: sodium humate 35g, polyacrylamide 10g, sodium polyacrylate 20g, potassium persulfate 3g, water 32g, first add 32g water to the reaction vessel, then add other raw materials, mix well, and keep the temperature constant Stand for 30 minutes, then add NaOH to neutralize to a pH value of 7 to prepare a mixed solution; then put the mixed solution into a microwave oven, and react for 20 minutes under the reaction conditions that the microwave frequency is 2450MHz and the power is 300W. Sodium humate-polyacrylamide-sodium polyacrylate copolymer is obtained; after the obtained copolymer is cooled, it is put into a grinder...

Embodiment 2

[0032] A composite ceramic dispersant is composed of the following raw materials by weight percentage: 55% of sodium humate, 10% of polyacrylamide, 15% of sodium polyacrylate, 2% of potassium persulfate and 18% of water.

[0033] Its preparation method comprises the following steps:

[0034] First, prepare raw materials according to the following weight percentages: sodium humate 55g, polyacrylamide 10g, sodium polyacrylate 15g, potassium persulfate 2g, water 18g, first add water to the reaction vessel, then add other raw materials, mix evenly, and place at a constant temperature 30 minutes, then add NaOH to neutralize to a pH value of 7 to prepare a mixed solution; then put the mixed solution into a microwave oven, and react for 15 minutes under the reaction conditions that the microwave frequency is 2450MHz and the power is 500W to prepare Sodium humate-polyacrylamide-sodium polyacrylate copolymer is obtained; after the obtained copolymer is cooled, it is put into a grinder ...

Embodiment 3

[0043] A composite ceramic dispersant is composed of the following raw materials by weight percentage: 60% of sodium humate, 8% of polyacrylamide, 17% of sodium polyacrylate, 1% of potassium persulfate and 14% of water.

[0044] Its preparation method comprises the following steps:

[0045]First prepare the raw materials according to the following weight percentages: sodium humate 60g, polyacrylamide 8g, sodium polyacrylate 17g, potassium persulfate 1g, water 14g, first add water to the reaction vessel, then add other raw materials, mix well, and place at a constant temperature 30 minutes, then add NaOH to neutralize to a pH value of 7 to prepare a mixed solution; then put the mixed solution into a microwave oven, and react for 15 minutes under the reaction conditions that the microwave frequency is 2450MHz and the power is 200W to prepare Sodium humate-polyacrylamide-sodium polyacrylate copolymer is obtained; after the obtained copolymer is cooled, it is put into a grinder fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Relative viscosity | aaaaa | aaaaa |

| Relative viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com