Preparation method of three-dimensional porous g-C3N4 material

A three-dimensional porous, g-c3n4 technology, applied in chemical instruments and methods, inorganic chemistry, organic compound/hydride/coordination complex catalysts, etc., can solve problems such as difficult recovery, low yield, and reduced photocatalytic activity , to achieve the effect of recycling and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

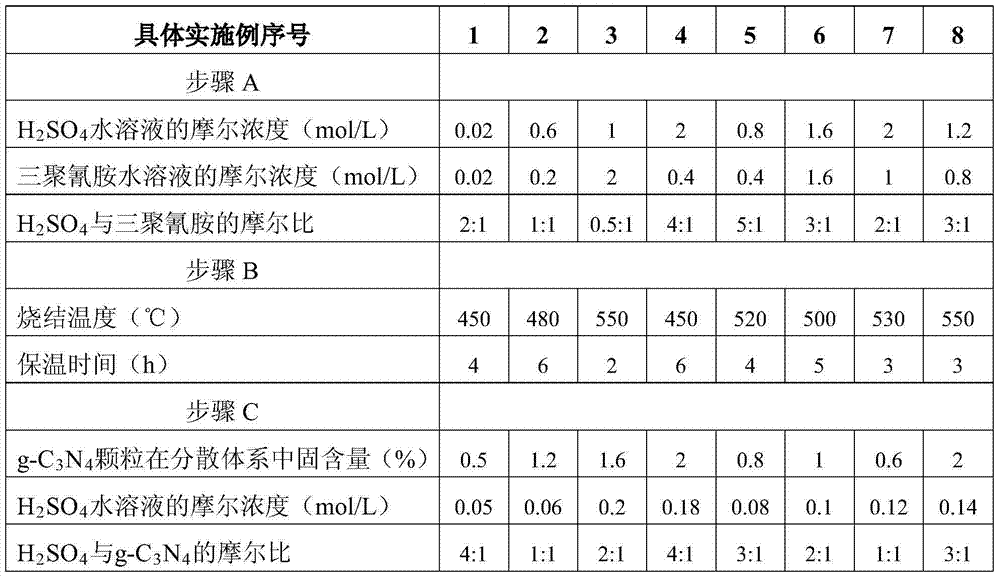

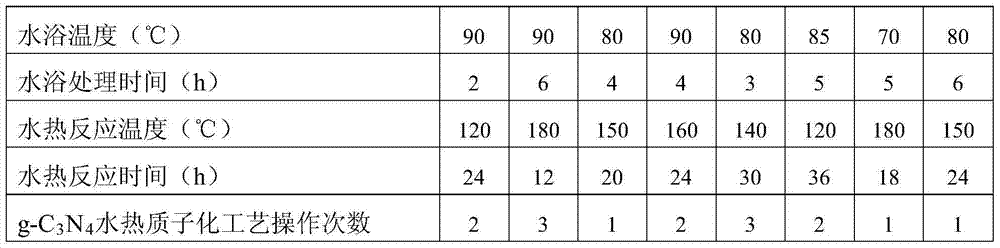

[0020] Three-dimensional porous g-C 3 N 4 The preparation method of the material includes the following steps:

[0021] Step A: Under stirring conditions, add H 2 SO 4 The aqueous solution was added dropwise to the 80°C melamine aqueous solution to form a white suspension; the precipitate was obtained after stirring for 2 hours; the precipitate was filtered and washed with distilled water and absolute ethanol three times, and dried at 60°C for 24 hours to obtain melamine sulfate;

[0022] Where the H 2 SO 4 The molar concentration of the aqueous solution is 0.02mol / L~2mol / L, the molar concentration of the melamine aqueous solution is 0.02mol / L~2mol / L, and the amount of reactants is controlled to make H 2 SO 4 The molar ratio to melamine is 5:1 to 0.5:1.

[0023] Step B: Put the melamine sulfate in a corundum boat, and then place it in a tube furnace for sintering. After cooling to room temperature, the obtained yellow polymer product is ground to powdery particles to obtain g-C 3 N 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com