Building brick and wall built by brick

A technology for building and brick body, which is applied in the direction of buildings, building components, building structures, etc. It can solve problems affecting construction operations, increasing construction costs, and increasing labor costs, so as to increase construction costs, reduce labor costs, and improve construction. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

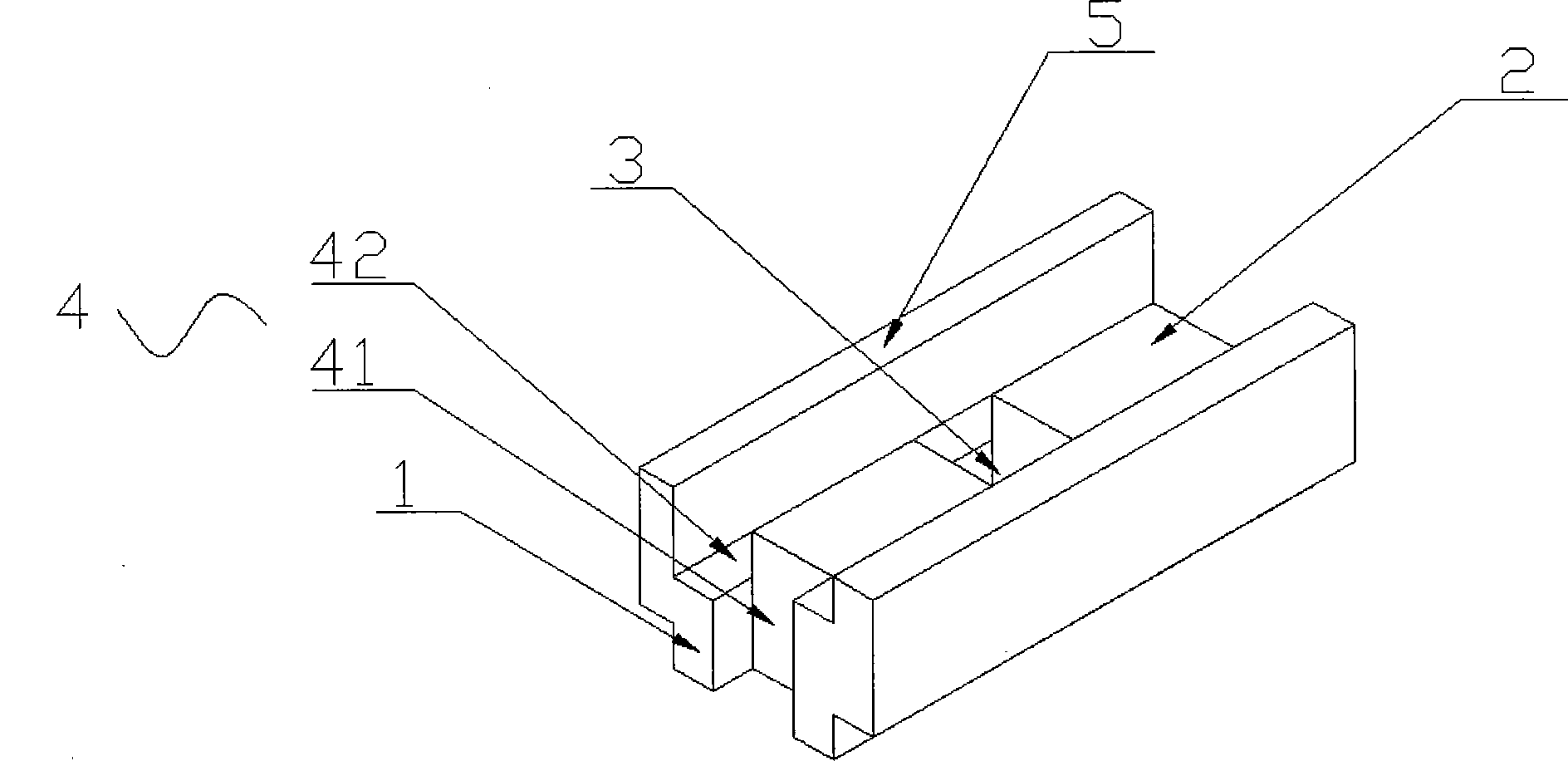

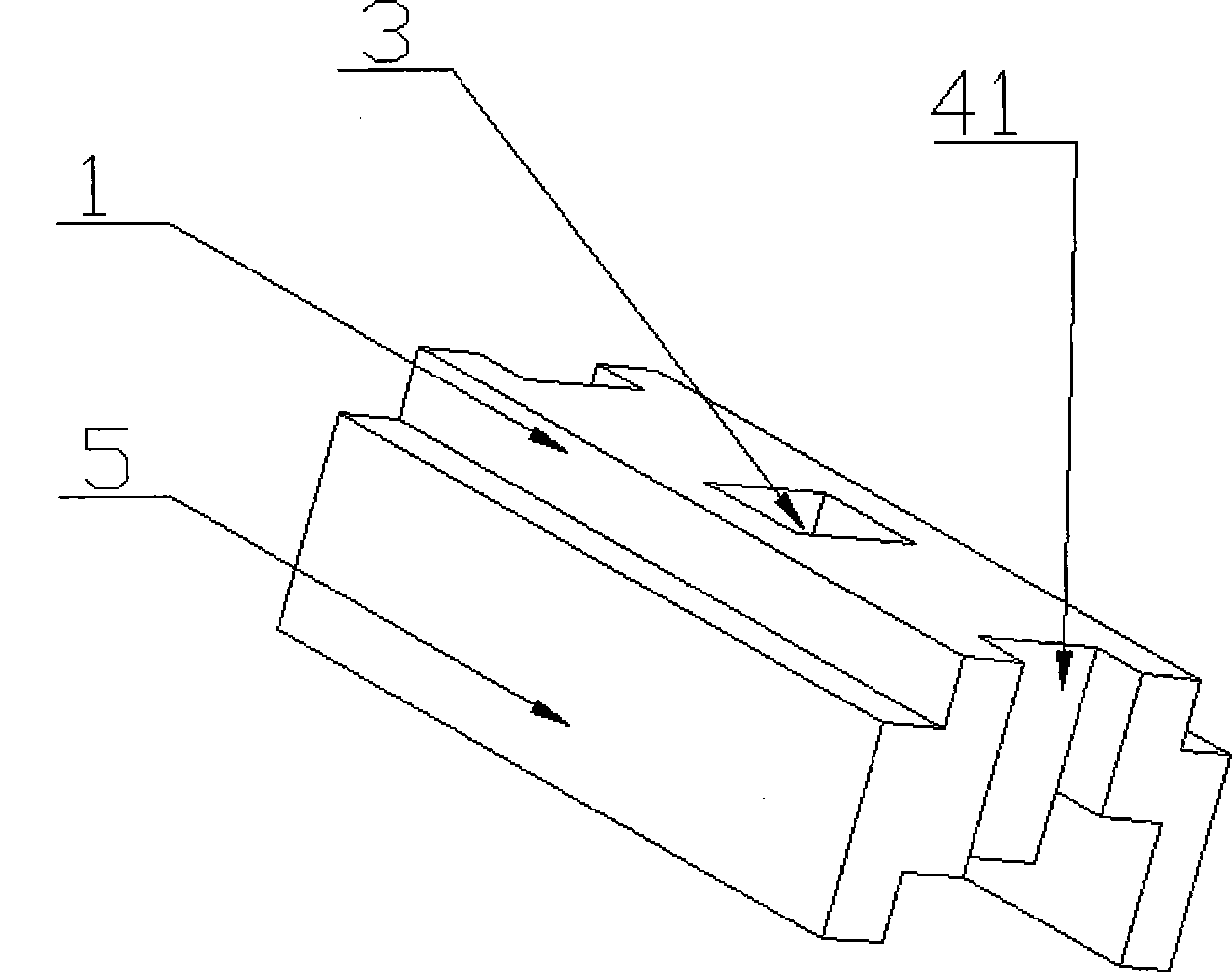

[0041] Such as Figure 1-Figure 2 As shown, a brick for building comprises a cuboid brick body, the brick body includes a convex hull 1 and a groove 2, and the convex hull 1 and the groove 2 are respectively arranged on two opposite sides; the brick body Several through holes 3 or / and several opening grooves 4 are arranged on the top, and the through holes 3 or / and opening grooves 4 all run through two opposite sides of the brick body.

[0042] The convex hull 1 is arranged on the lower surface of the brick body, the groove 2 is arranged on the upper surface of the brick body, and the two sides of the groove 2 are provided with an upwardly extending extension plate 5, and the groove 2 is the space between the two extension plates 5, the projection of the convex hull 1 on the vertical plane perpendicular to it is a rectangle, and the upper surface of the convex hull 1 is a plane and parallel to the lower surface of the brick body. The center line of the through hole 3 coincide...

Embodiment 2

[0048] The building brick described in this embodiment has basically the same structure as that in Embodiment 1, the difference being that: at least one of the front side and the rear side of the brick body is bonded with a smooth porcelain layer.

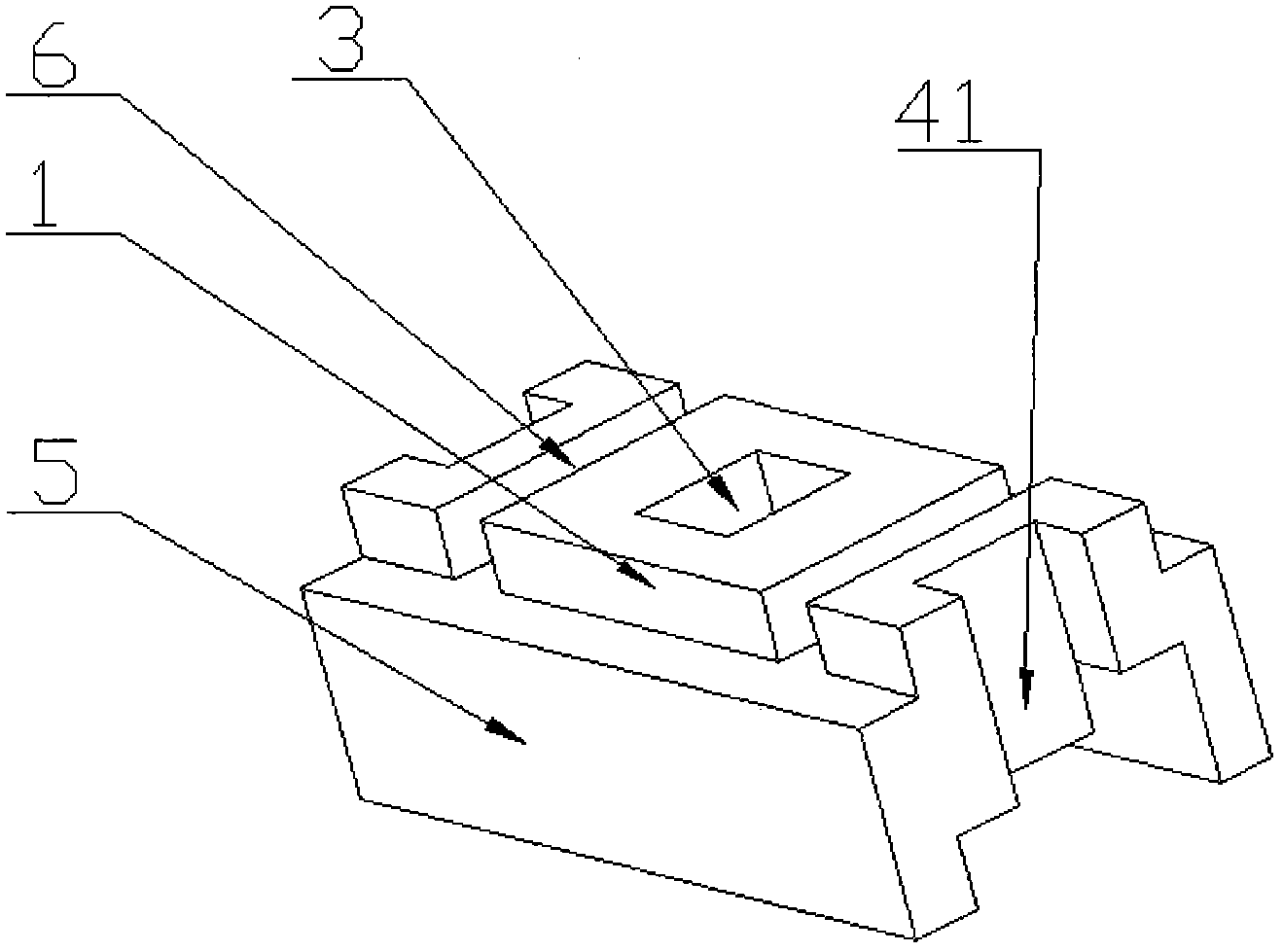

[0049] When the building is made of the wall described in Embodiment 2, the porcelain layer adopts the material and manufacturing process of ceramic tiles. When building the wall, the side with the porcelain layer is stacked on the inner wall, which can save a lot of money. Subsequent decoration such as: the cost of plastering and bonding tiles; the convex shell 1 can be provided with a clamping groove 6, which can realize the vertical stacking of the brick body of this layer and the brick body of the adjacent layer, and the layer formed by the adjacent brick body A horizontal tension is formed between them to make the wall more stable.

Embodiment 3

[0051] Such as image 3 As shown, the structure of the building brick described in this embodiment is basically the same as that of Embodiment 1, the difference is that: the convex hull 1 is provided with a locking groove 6 perpendicular to the extending direction of the convex hull 1, The clamping groove 6 cooperates with the two extension plates 5 forming the groove 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com