Detection method of trace vanadium volatilization rate in vanadium-based selective catalyst

A detection method and catalyst technology, which are used in the preparation of test samples, analytical materials, instruments, etc., to achieve the effect of reducing the difficulty of digestion, simple calculation method, and reducing the amount of sample weighing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Take a small sample: Use a cutting tool such as an angle grinder to peel off the metal package shell of the complete ceramic carrier vanadium-based selective catalyst sample, take out a large sample of the vanadium-based selective catalyst, and use a sampling tool to take two samples from the large catalyst sample. Catalyst small sample, small sample volume is 0.02L.

[0034] (2) Small sample hydrothermal aging: A hydrothermal aging simulation reactor was used to perform rapid hydrothermal aging on one of the vanadium-based selective catalyst samples. The hydrothermal aging conditions were: 600°C, water vapor content 10%, and aging time 50h.

[0035] (3) Sample preparation: the fresh catalyst sample and the aged catalyst sample were respectively pulverized and ground to below 200 mesh to obtain two sample samples.

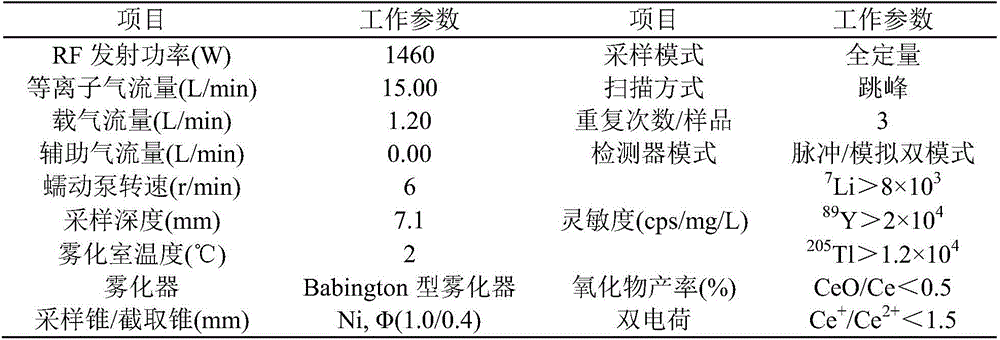

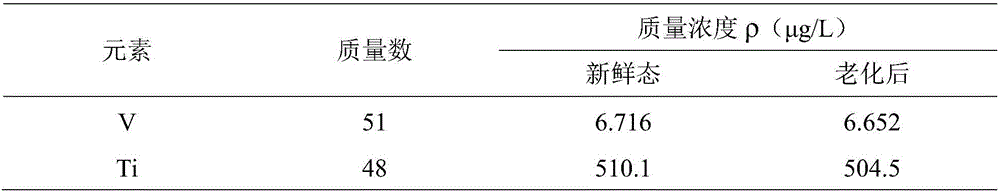

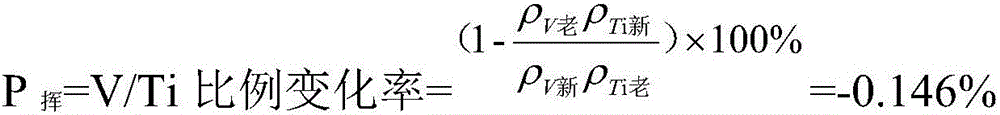

[0036] (4) Preparation and analysis of sample test solution: take 2 parallel samples of 0.01 g from the two samples respectively, and carry out heating ...

Embodiment 2

[0065] (1) Aging on the engine bench

[0066] Take two SCR devices of the same batch, and one of them is subjected to a 100h durability test on the engine bench according to HJ451-2008 "Technical Requirements for Environmental Protection Products Diesel Vehicle Exhaust Aftertreatment Devices", and then unloaded from the bench.

[0067] (2) Take a small sample: Cut off the exhaust pipes at the inlet ends of the two SCR devices respectively, and dig about 1g of sample powder at the center of the inlet ends of the vanadium-based selective catalyst.

[0068] (3) Sample preparation: Grind fresh and aged catalyst samples to below 200 mesh respectively.

[0069] (4) Analysis: Take 2 parallel samples of 0.1g from the two samples respectively, place the samples in a polytetrafluoroethylene digestion tank, add 10mLHCl, 2mLHNO 3 , 1mLHF, 5mLH 2 O, digested at 210°C for 15 minutes under a sealed seal. After cooling to room temperature, open the can, transfer the test solution to a PET ...

Embodiment 3

[0079] (1) Take a small sample: Use a cutting tool such as an angle grinder to peel off the metal package shell of the complete ceramic carrier vanadium-based selective catalyst sample, take out a large sample of the vanadium-based selective catalyst, and use a sampling tool to take two samples from the large catalyst sample. Catalyst small sample, small sample volume is 0.08L.

[0080] (2) Small sample hydrothermal aging: A hydrothermal aging simulation reactor was used to perform rapid hydrothermal aging on one of the vanadium-based selective catalyst samples. The hydrothermal aging conditions were: 850°C, 20% water vapor content, and 400h aging time.

[0081] (3) Sample preparation: the fresh catalyst sample and the aged catalyst sample were respectively pulverized and ground to below 200 mesh to obtain two sample samples.

[0082] (4) Preparation and analysis of sample test solution: take 0.9 g of two parallel samples of the two samples respectively, and carry out digestio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com