A sample axial erosion corrosion test device and method

A technology of erosion corrosion and test equipment, which is applied in the direction of measuring equipment, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of high performance requirements of mechanical pumps, high construction and operation costs, low fluid flow rate, etc., to achieve the test Effects of compact device, large device scale, and low construction and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

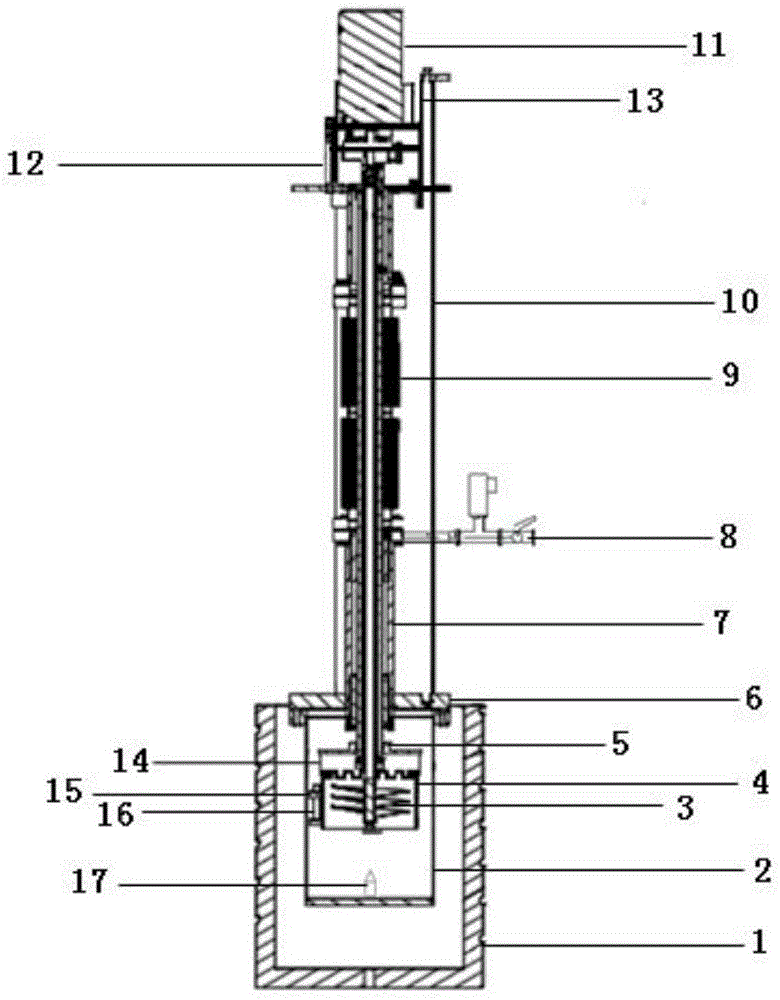

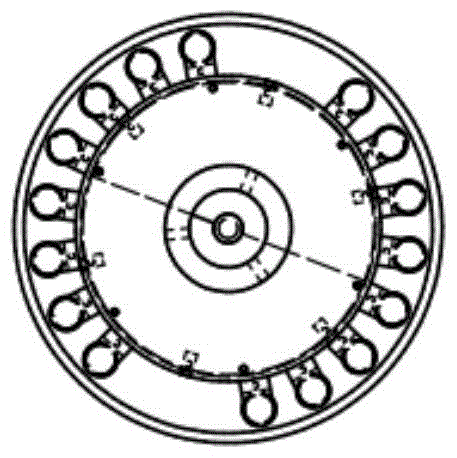

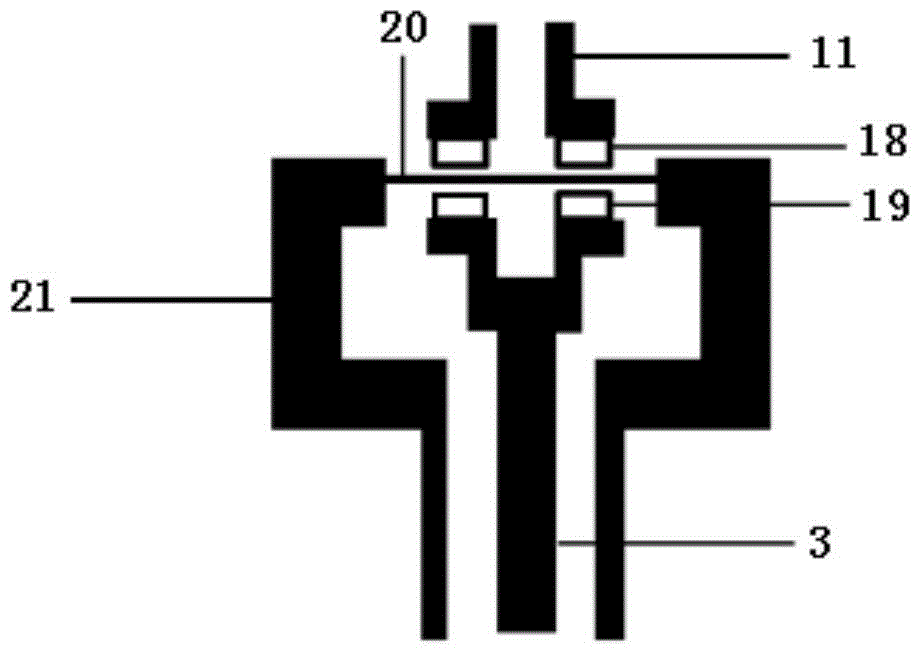

Embodiment 1

[0043] Implementation Example 1: According to the above description, a liquid lead-bismuth alloy corrosion experiment device was designed and developed and a corrosion experiment was carried out. The motor 11 is a high-power stepping motor; the number of threads of the screw type stirring paddle 3 is 3.5; the sample 16 is 16 outer Stainless steel hollow rods with the same diameter and height, the sample 16 is installed and fixed on the outer wall of the guide tube 4 through the sample holder 15. The corrosion test procedure is as follows:

[0044] (1) Add a solid lead-bismuth block with a calculated weight into the tank body 2, put the guide tube 4 and the screw-type stirring paddle 3 with the sample 16 installed, and seal the tank body top cover 6.

[0045] (2) Open the vacuum system 8, replace the air in the bellows 9 and the tank body 2 with argon, and close the vacuum system 8.

[0046] (3) Open the heating and heat preservation system 1 outside the tank body 2 to heat th...

Embodiment 2

[0052] Implementation example 2: Use water to calibrate the driving efficiency of the corrosion experimental device, the calculation process is as follows:

[0053] η = 4 × Q π × ( D 2 - d 2 ) × ( H - h ) × ω

[0054] In the formula:

[0055] η is the driving efficiency of the test device;

[0056] D is the diameter of the screw type impeller;

[0057] d is the diameter of the drive shaft of the screw-type stirring paddle;

[0058] H is the pitch of the screw-type stirring paddle blade;

[0059] h is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com