A catalyst used for oxidation of elementary substance mercury in coal-fired flue gas, and a preparation method and a regeneration method of the catalyst

A technology of coal-fired flue gas and catalyst, which is applied in the directions of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of low catalytic oxidation efficiency of catalysts, inability to recycle catalysts, and inability to separate catalysts. Excellent catalytic oxidation performance, good economic benefits, and the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

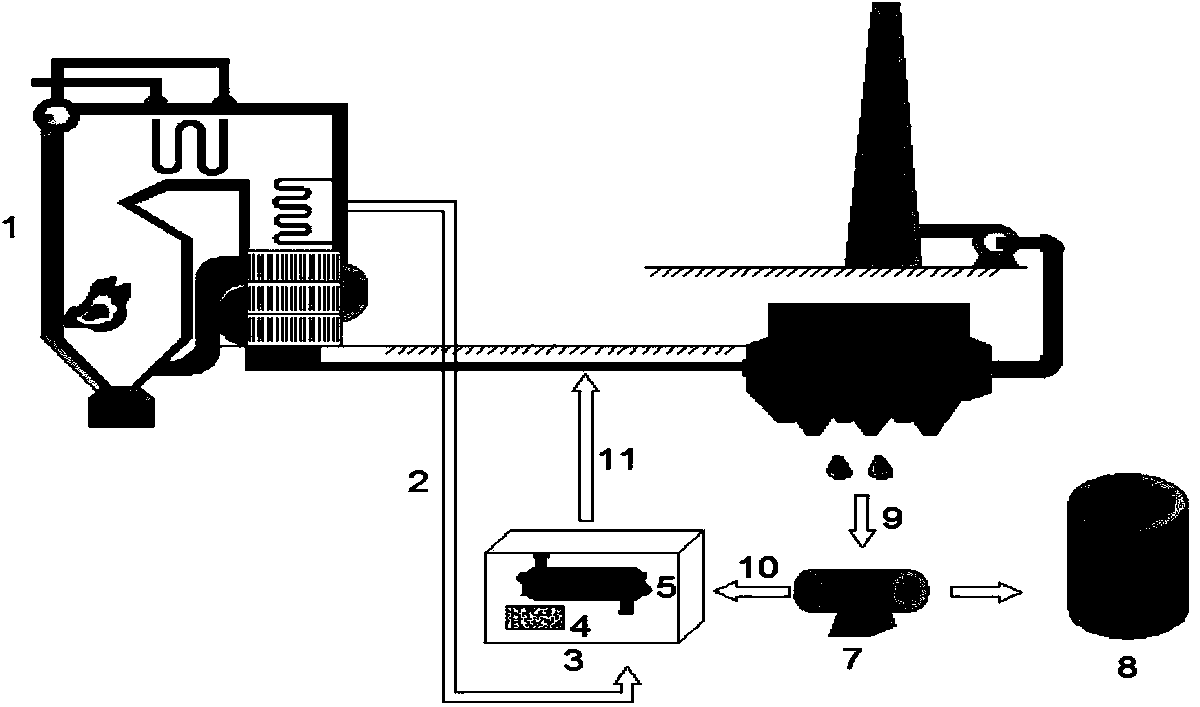

Method used

Image

Examples

Embodiment 1

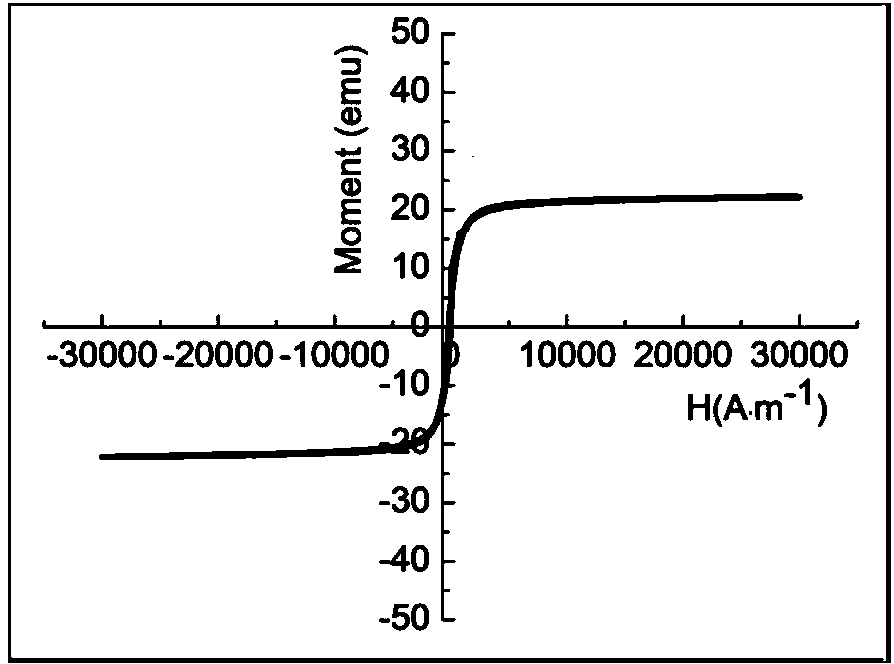

[0034] A magnetic separator is used to separate the magnetic beads from the fly ash, and after grinding, a 200-mesh standard sieve is used to screen the magnetic beads with a suitable particle size. Measure 0.2g CuCl 2 2H 2 O in a beaker, add 100ml deionized water and stir until completely dissolved, then add 2 2 g of magnetic beads were added to the aqueous solution, and mechanically stirred at room temperature for 2 hours, the magnetic beads loaded with active components were filtered and then dried in an oven at 100° C. for 12 hours to obtain the catalyst. The mass ratio of the active component to the support in the catalyst is 10%. The hysteresis curves of the prepared catalysts are shown in the attached figure 2 As shown, the catalyst exhibits superparamagnetism, so the catalyst after adsorbing mercury can be easily separated from the fly ash by magnetic separation for recycling.

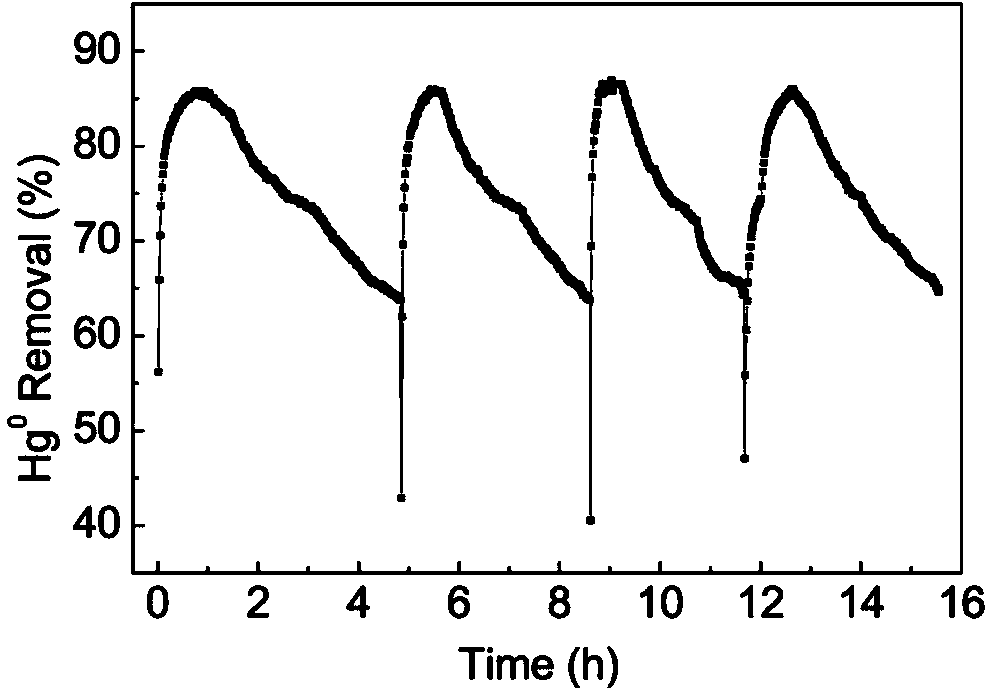

[0035] The catalyst prepared above was placed in a fixed-bed reactor to evaluate the c...

Embodiment 2

[0040] A magnetic separator is used to separate the magnetic beads from the fly ash, and after grinding, a 200-mesh standard sieve is used to screen the magnetic beads with a suitable particle size. Measure 0.1g CuCl 2 2H 2 O in a beaker, add 50ml deionized water and stir until completely dissolved, then slowly add 2g magnetic beads under continuous stirring, and mechanically stir for 2 hours at room temperature, filter the magnetic beads loaded with active components and put them in an oven Dry at 100°C for 12 hours to obtain the catalyst. The mass ratio of the active component to the support in the catalyst is 3%. The hysteresis curve of the prepared catalyst is similar to that of the catalyst described in Example 1, and will not be repeated here.

[0041] The catalyst prepared above was placed in a fixed-bed reactor to evaluate the catalytic oxidation activity of mercury, wherein the simulated flue gas component was 4% O 2 ,12%CO 2 ,10ppm HCl,1200ppmSO 2 ,300ppm NO,50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com