Modified manganese oxide catalyst, preparation method and application thereof

A manganese oxide and catalyst technology, applied in the field of modified manganese oxide catalyst and its preparation, can solve the problems of unfavorable industrial application and high catalyst cost, and achieve the effects of excellent catalytic oxidation performance, excellent resistance to high space velocity, and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] The preparation method of modified manganese oxide catalyst:

[0088] (1) preparing manganese oxide, the preparation method of described manganese oxide comprises the following steps:

[0089] (1) add glacial acetic acid in the manganese acetate aqueous solution that concentration is 0.75mol / L, obtain the first mixed solution, the mol ratio of manganese acetate and glacial acetic acid in the first mixed solution of gained is 1:3;

[0090] (2) concentration is that the aqueous potassium permanganate solution of 0.32mol / L is added in the first mixed solution of step (1) gained, obtains the second mixed solution, the potassium permanganate in the described potassium permanganate aqueous solution and step ( 1) The molar ratio of manganese acetate in the manganese acetate aqueous solution is 0.87:1

[0091] (3) subjecting the second mixed solution obtained in step (2) to hydrothermal treatment at 100°C for 24 hours, and roasting at 700°C for 3 hours to obtain the manganese ...

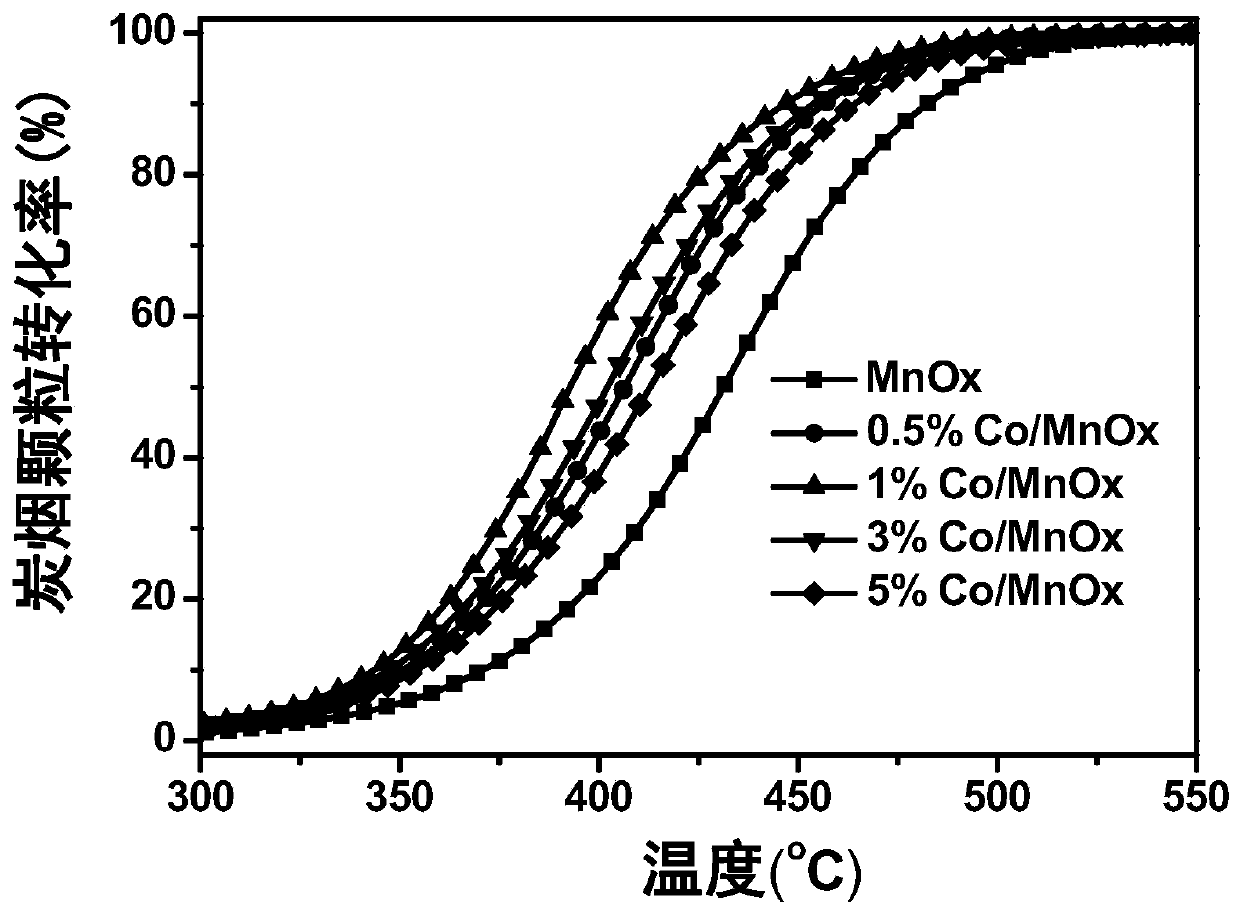

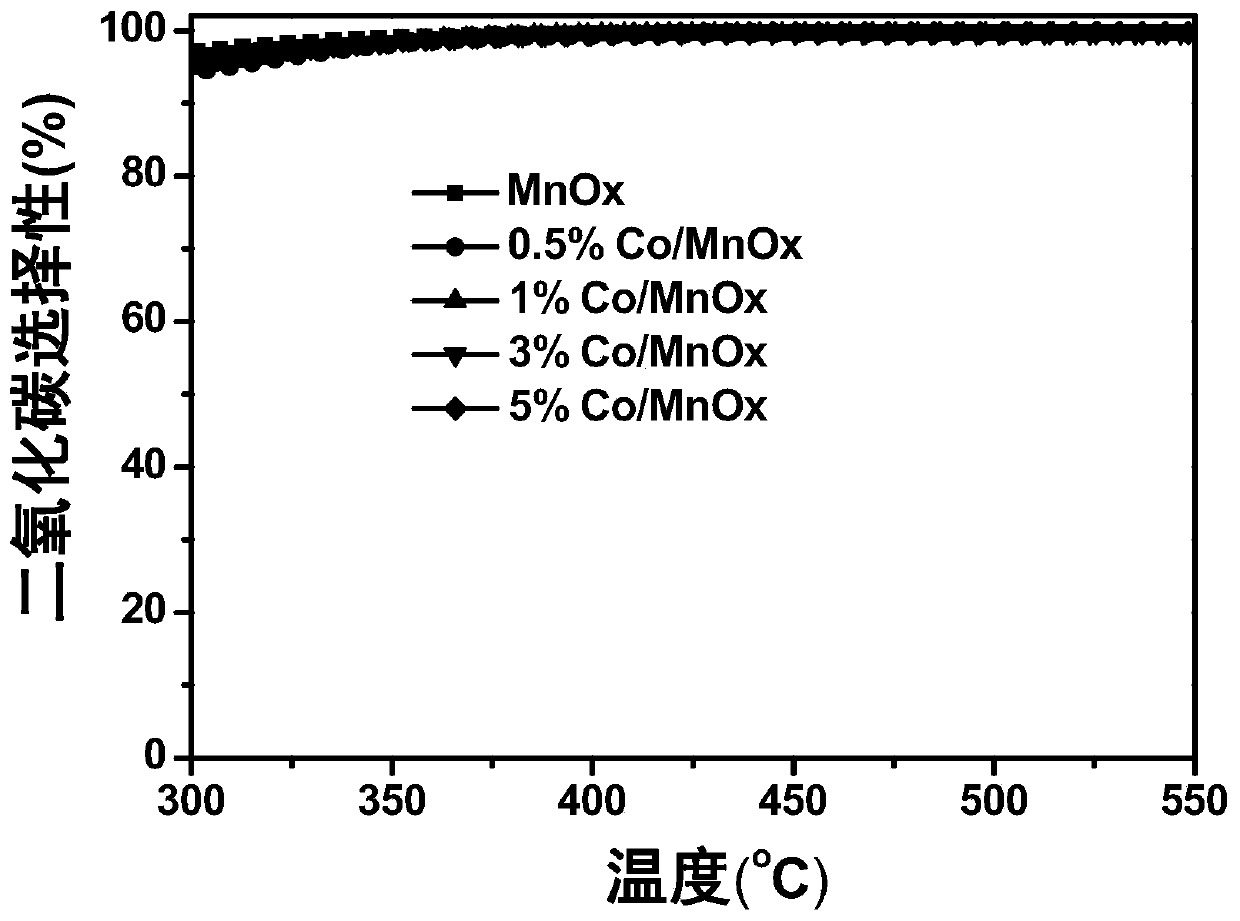

Embodiment 2

[0094] The difference between this embodiment and embodiment 1 is that in step (II) Co(NO 3 ) 2 ·6H 2 The concentration of O aqueous solution is replaced by 6.81×10 -3 mol / L, other conditions are identical compared with embodiment 1;

[0095] The loading capacity of Co element on the catalyst obtained in this example is 1%, and the catalyst is recorded as 1% Co / MnO x .

Embodiment 3

[0097] The difference between this embodiment and embodiment 1 is that in step (II) Co(NO 3 ) 2 ·6H 2 The concentration of O aqueous solution is replaced by 20.4×10-3 mol / L, other conditions are identical compared with embodiment 1;

[0098] The loading capacity of Co element on the catalyst obtained in this embodiment is 3%, and the catalyst is recorded as 3% Co / MnO x .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com