Silica nanosphere supported molybdenum oxide quantum dot catalyst and preparation method thereof

A silica and nanosphere technology, applied in metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the synthesis method of supported molybdenum oxide quantum dot catalytic material Unrealized and other problems, to achieve the effects of excellent catalytic oxidation performance, uniform particle morphology, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

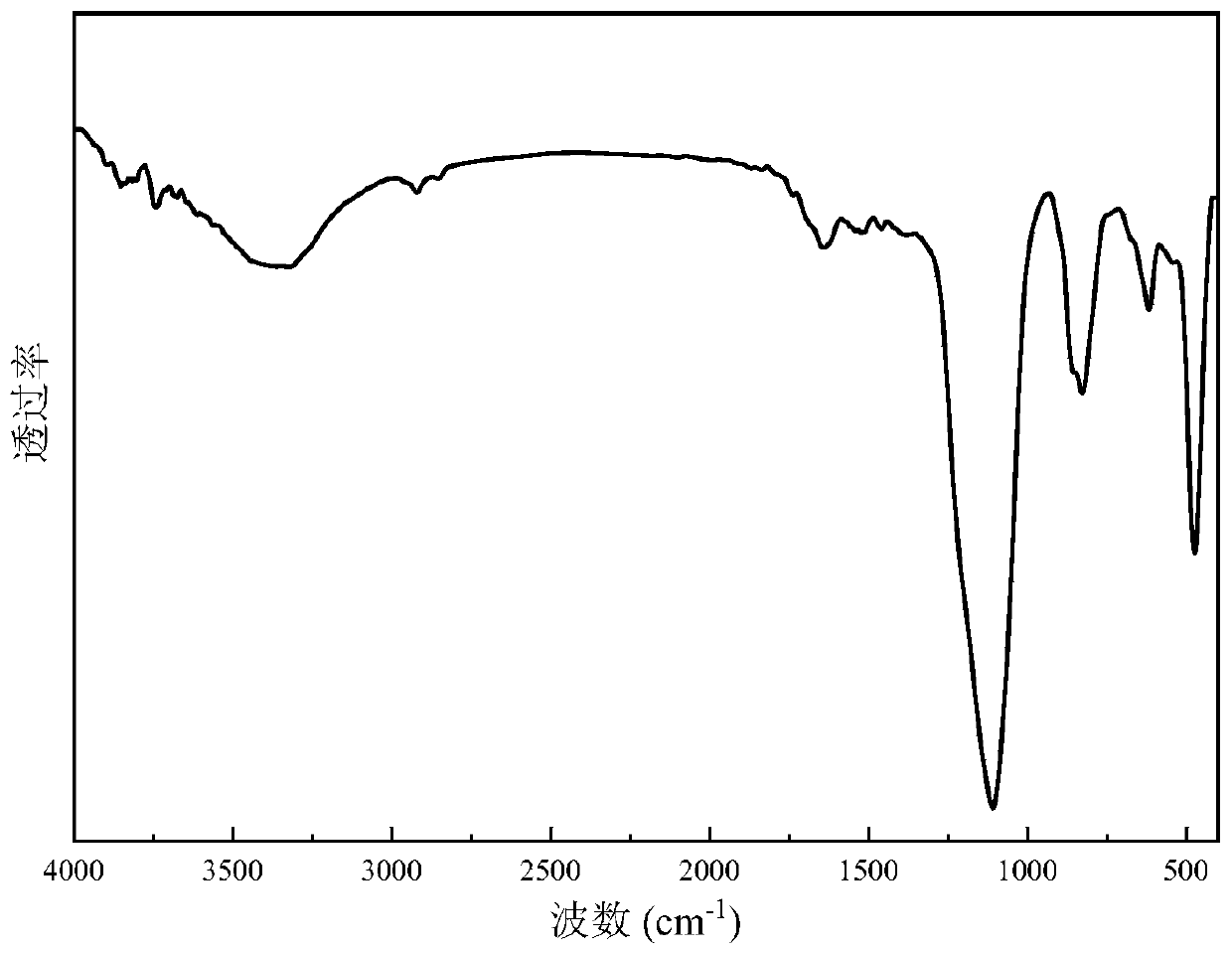

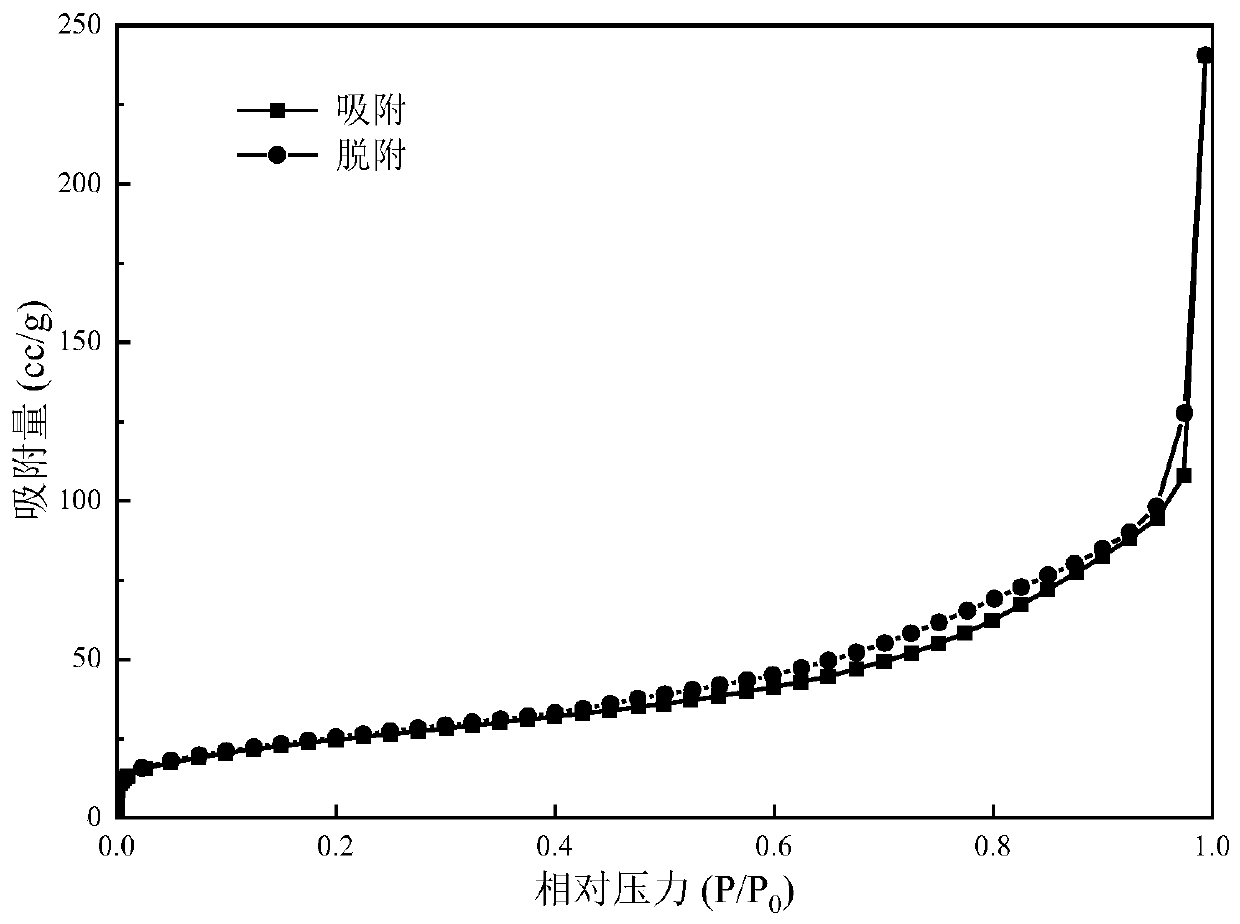

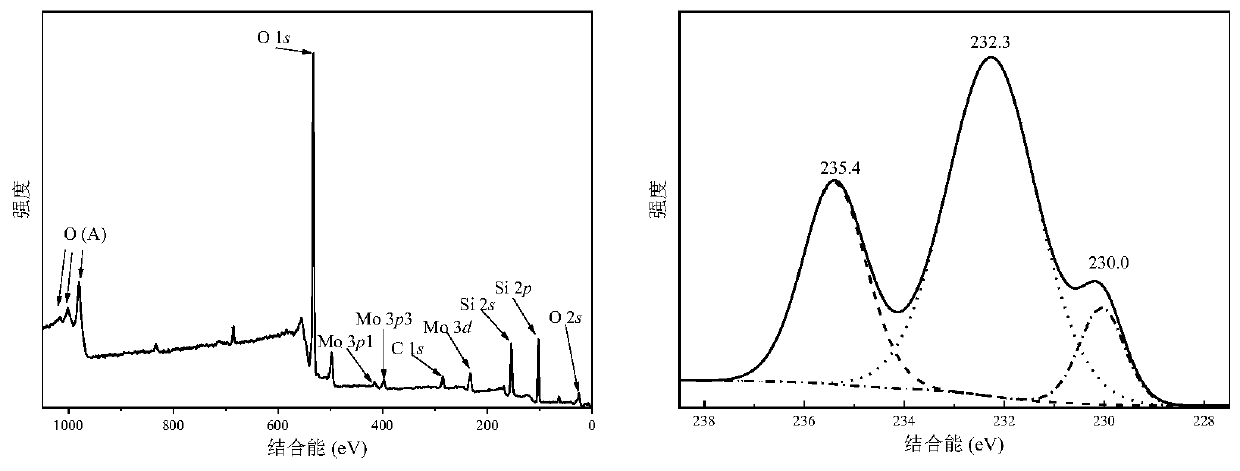

[0029] The mol ratio of Mo and Si is 0.125 in this example, and concrete preparation steps are as follows:

[0030] 0.09g of MoS 2 The powder and prepared silica nanospheres of corresponding quality were dissolved in 6 mL deionized water, and mixed under magnetic stirring until MoS 2 Mix the powder and silica nanospheres evenly, add 4mL hydrogen peroxide (30%, wt), react at room temperature for 10min, and then titrate the reaction solution to neutrality with 10.0mol / L NaOH solution, after titration, the sample is placed at 8000rpm Centrifuge for 10 minutes, take the precipitate and wash it with deionized water, then centrifuge at 8000rpm for 10 minutes, repeat the above operation for more than 3 times, and finally dry it in vacuum at 60°C to obtain the catalyst sample. Such as Figure 4 As shown, the average particle size of the samples prepared in this embodiment is about 300nm.

Embodiment 2

[0032] In this example, the reaction time is 20min, and the concrete preparation steps are as follows:

[0033] According to the molar ratio of Mo and Si is 0.125, 0.09g of MoS 2 The powder and prepared silica nanospheres of corresponding quality were dissolved in 6 mL deionized water, and mixed under magnetic stirring until MoS 2 Mix the powder and silica nanospheres evenly, add 4mL hydrogen peroxide (30%, wt), react at room temperature for 20min, then titrate the reaction solution to neutrality with 10.0mol / L NaOH solution, after titration, the sample is placed at 8000rpm Centrifuge for 10 minutes, take the precipitate and wash it with deionized water, then centrifuge at 8000rpm for 10 minutes, repeat the above operation for more than 3 times, and finally dry it in vacuum at 60°C to obtain the catalyst sample. Such as Figure 5 As shown, the average particle diameter of the samples prepared in this embodiment is about 330nm.

Embodiment 3

[0035] This example is a silica nanosphere-supported molybdenum oxide quantum dot catalyst to test the catalytic oxidation desulfurization performance of organic sulfur compounds. The selected sample is the silica nanosphere-supported molybdenum oxide quantum dot catalyst in Example 1. The used The target sulfur compound is benzothiophene.

[0036] Add 10mL of 400ppm benzothiophene model oil, 0.05g of catalyst and 30μL of hydrogen peroxide into a round-bottomed flask, and then place it in a constant temperature water bath with a preset temperature for reaction. After the reaction time is up, immediately take out the reaction flask and put it in ice water After cooling, constant volume and centrifugation, the upper organic phase was taken for sulfur content determination. As shown in the figure, the desulfurization rate of the sample prepared in this embodiment is 92.57%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com