AgBr-Co3O4-BiOBr composite material as well as preparation method and application thereof

A composite material and solvothermal reaction technology, which is applied in the preparation of carbon-based compounds, organic compounds, chemical instruments and methods, etc., can solve the problems of unsatisfactory selectivity and low efficiency of electron-hole separation, and achieve easy operation , low cost, high catalytic selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

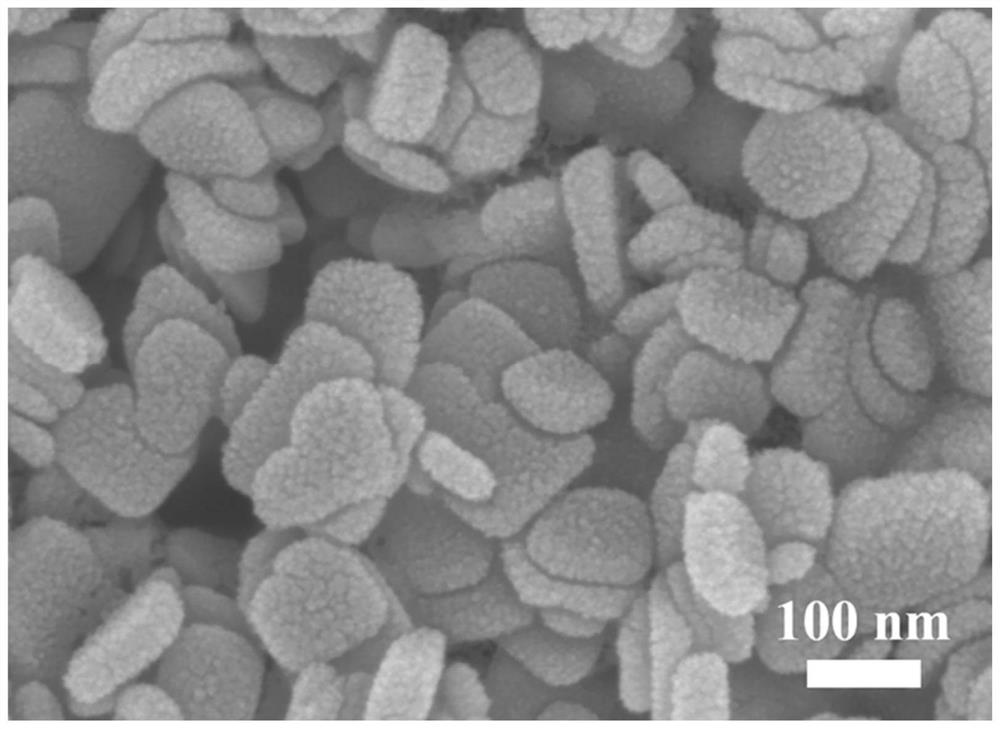

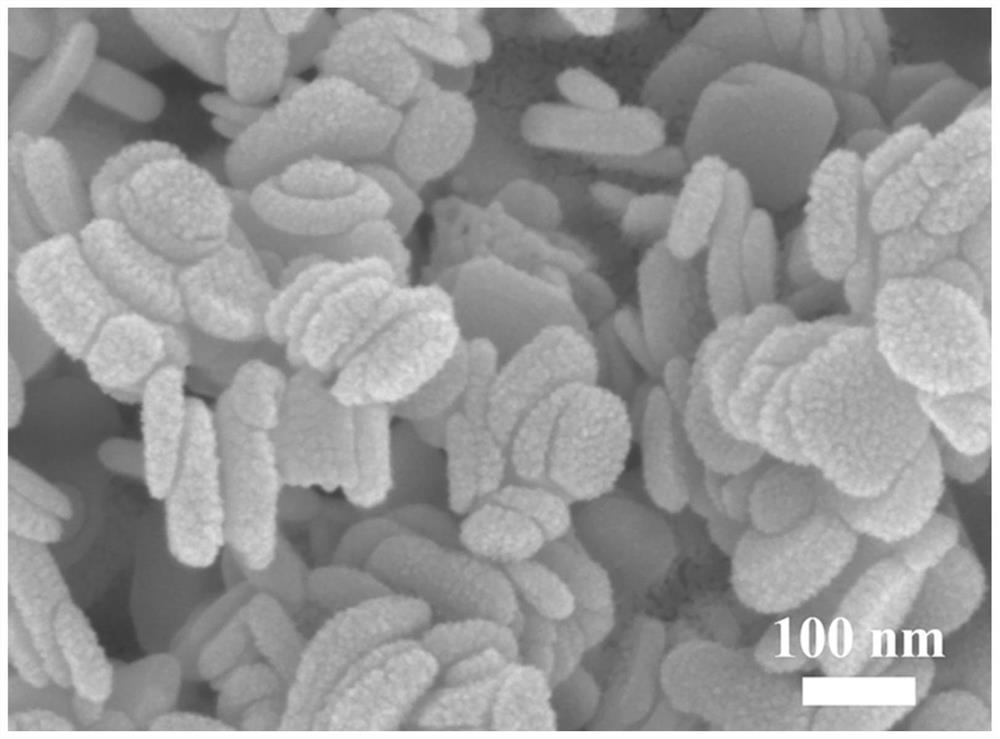

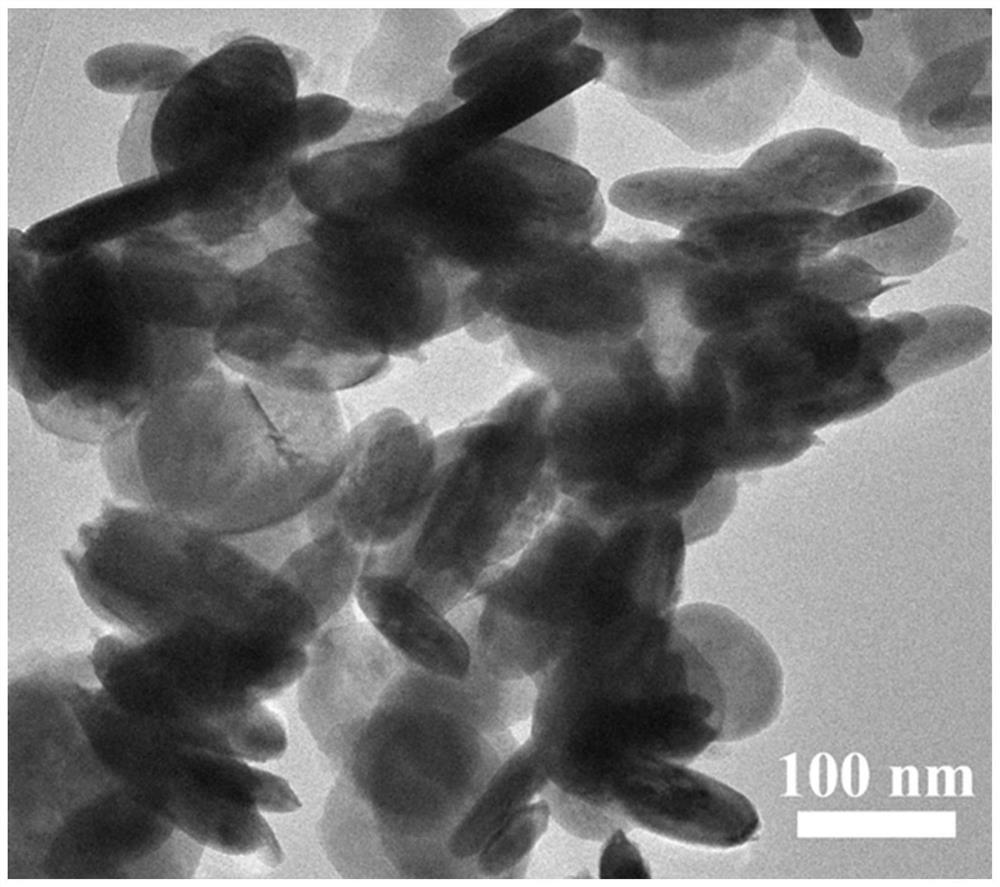

[0054] a AgBr-Co 3 o 4 -BiOBr composite material, its preparation method comprises the following steps:

[0055] S1: Synthesis of BiOBr nanosheet materials:

[0056] Weigh 0.1191g of potassium bromide and add it to 10mL of deionized water, ultrasonically disperse evenly to obtain a potassium bromide solution, weigh 0.4853g of bismuth nitrate pentahydrate and add it to 20mL of ethylene glycol and stir until dissolved to obtain a bismuth nitrate solution, then dissolve the potassium bromide solution Add it dropwise into the bismuth nitrate solution, stir vigorously for 30 minutes, then transfer the resulting mixed solution into a reaction kettle for solvothermal reaction, keep it at 120°C for 6 hours, cool it naturally to room temperature after the reaction, and wash the obtained product with deionized water and anhydrous ethanol for 3 times, and then dried in a drying oven at 60°C, taken out and ground to obtain a powdered BiOBr material;

[0057] S2: Synthesis of AgBr-Co 3...

Embodiment 2

[0070] BiOBr nanometer material and AgBr-Co prepared by comparative example 1 3 o 4 -BiOBr composite photocatalytic selective oxidation of toluene to benzaldehyde performance difference:

[0071] Get 50mg powder samples (respectively BiOBr nano material and AgBr-Co prepared in embodiment 1) 3 o 4 -BiOBr composite material) was dispersed in 10mL of acetonitrile, ultrasonically dispersed for 10min, put into the photocatalytic reaction container, then added 1mmol of toluene and continuously stirred oxygen bubbling for 30min, the temperature of the circulating cooling water was kept at room temperature, and the reactor 4 was continuously illuminated with a 300W xenon lamp hours, centrifuged after the reaction, and the liquid product was detected by gas chromatography, and the reaction product and the amount of production were judged according to the peak position and the peak area of the gas chromatography and gas chromatography-mass spectrometry. BiOBr nanomaterials and AgBr...

Embodiment 3

[0079] The AgBr-Co prepared by Comparative Example 1 3 o 4 -BiOBr composite photocatalytic selective oxidation of toluene homologue performance:

[0080] Get many parts of 50mg powder samples (AgBr-Co prepared by embodiment 1 3 o 4 -BiOBr composite material), each part was dispersed in 10mL acetonitrile, ultrasonically dispersed for 10min, then placed in a photocatalytic reaction container, and then 1mmol of toluene homologue was added to each part, and oxygen bubbling was continuously stirred for 30min, and the temperature of circulating cooling water was kept at room temperature , use a 300W xenon lamp to continuously illuminate the reactor for 4 hours, centrifuge after the reaction, and detect the liquid product by gas chromatography, and judge the reaction product and production amount according to the peak position and peak area of the gas chromatography and gas chromatography-mass spectrometry. AgBr-Co of the present invention 3 o 4 The substrate conversion and se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com