A kind of L-shaped steam seal sheet molding device and production method

An air-sealing sheet and L-shaped technology, which is applied in the field of L-shaped steam-sealing sheet forming devices, can solve the problems of low product precision, cumbersome and time-consuming processes, no steam-sealing sheet device and production method involved, etc., so as to achieve mass production and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the drawings and embodiments of the description.

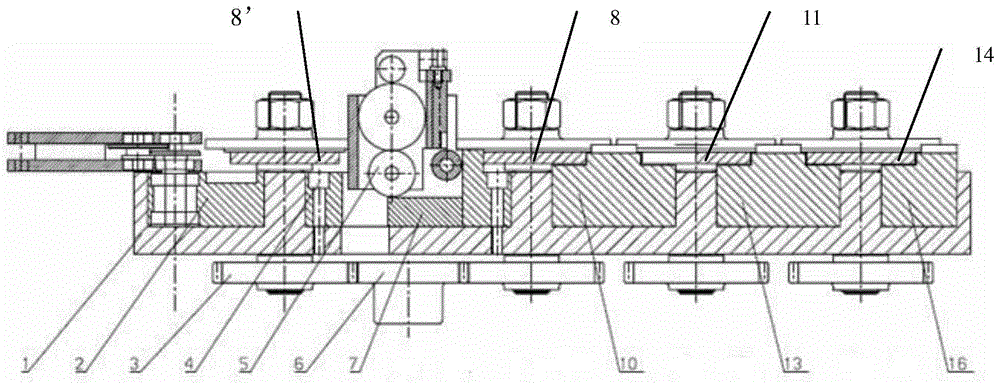

[0049] like figure 1 , 2 As shown, the L-shaped steam seal forming device of the present invention is mainly composed of a fuselage, a forming wheel device, a planing device, an arc bending device, a gear transmission device and the like.

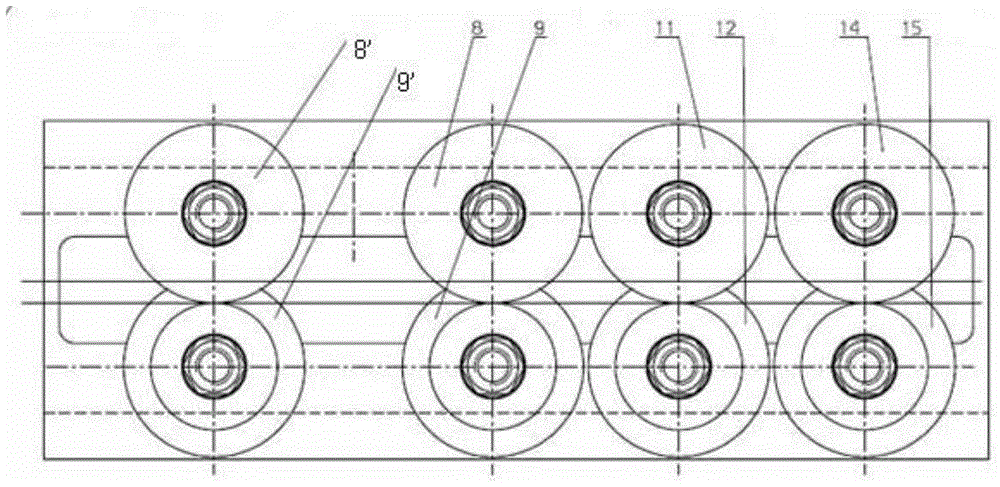

[0050] Wherein, the specific position structure and connection mode of the gear transmission device are as follows: figure 2 shown.

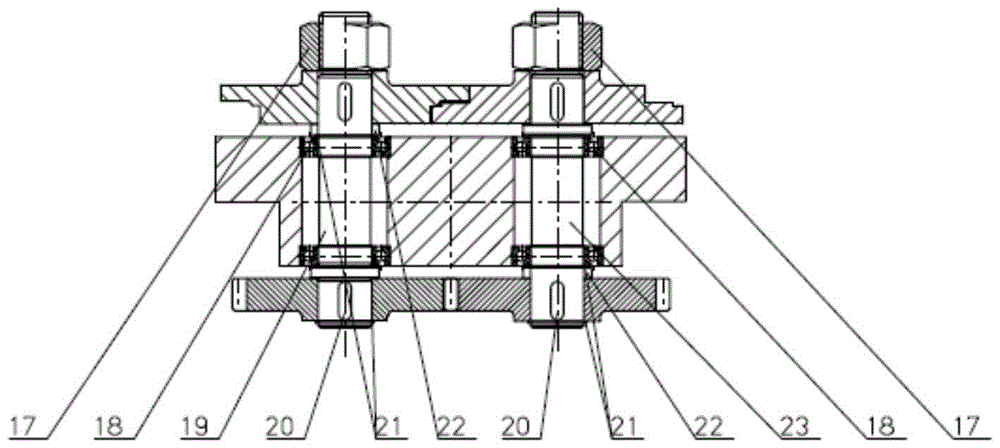

[0051] like figure 1 , 2, 3, the described forming wheel device includes: 1#, 2# main shafts 19, 23 are fixed on the fuselage 1 by positioning sleeves 22, angular contact ball bearings 18, and shaft circlips 21; The main shaft 19,23 is connected with the gear; the hexagonal nut 17 connects and fixes the first forming upper and lower wheels 14,15 and 1#, 2# main shafts 19,23; the first forming upper and lower wheels 14,15; the second Form upper and lower wheels 11, 12 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com