Preparation method of conductive polymer film having inverse opal structure

An inverse opal structure, conductive polymer technology, applied in the electrolysis process, electrolysis components, electrolysis organic production and other directions, to achieve the effect of good structural environmental stability, shortening the distance that the balance ions in the electrolyte enter the membrane, and improving the color conversion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The monomer is 1,4-bis(2-thiophene)benzene (BTB), and its structure is as follows:

[0052]

[0053] Operation process:

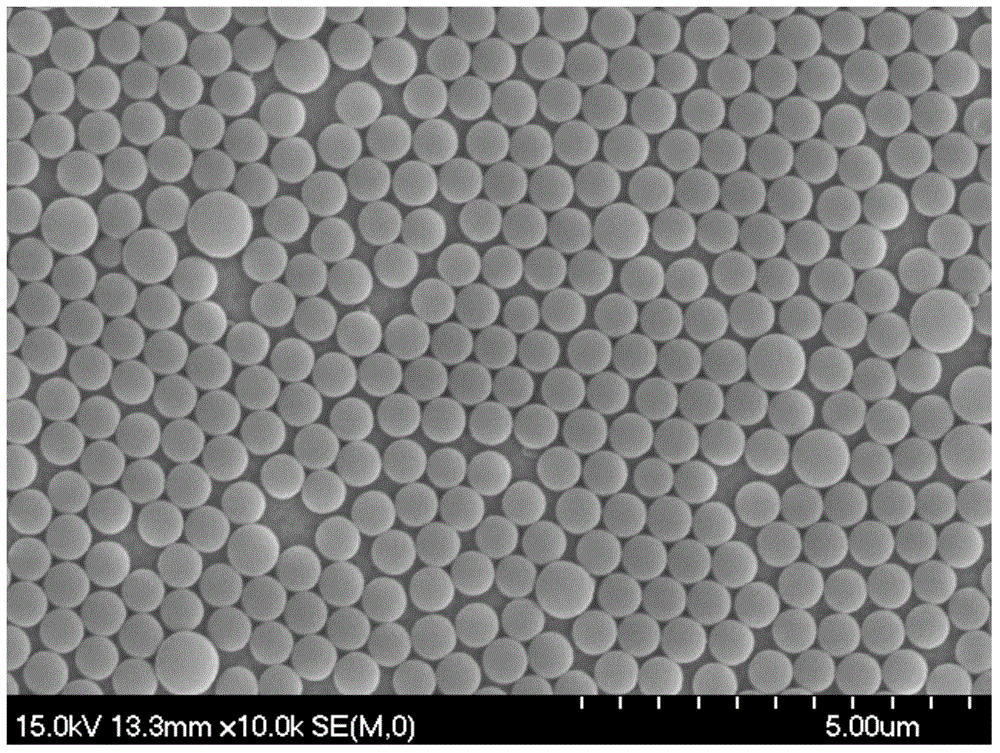

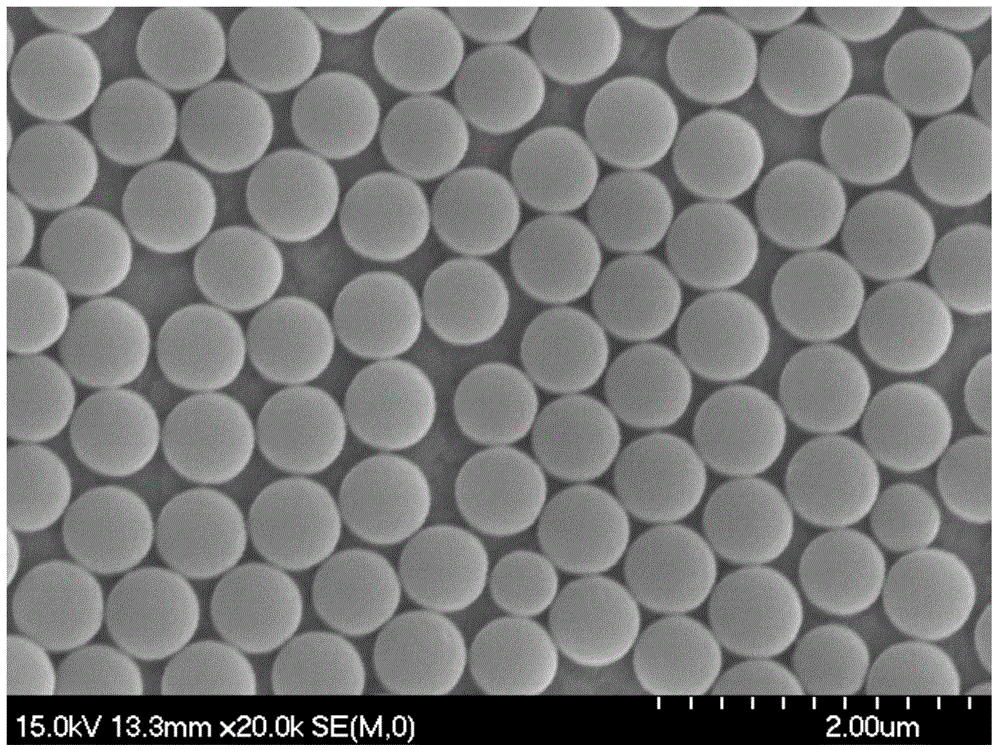

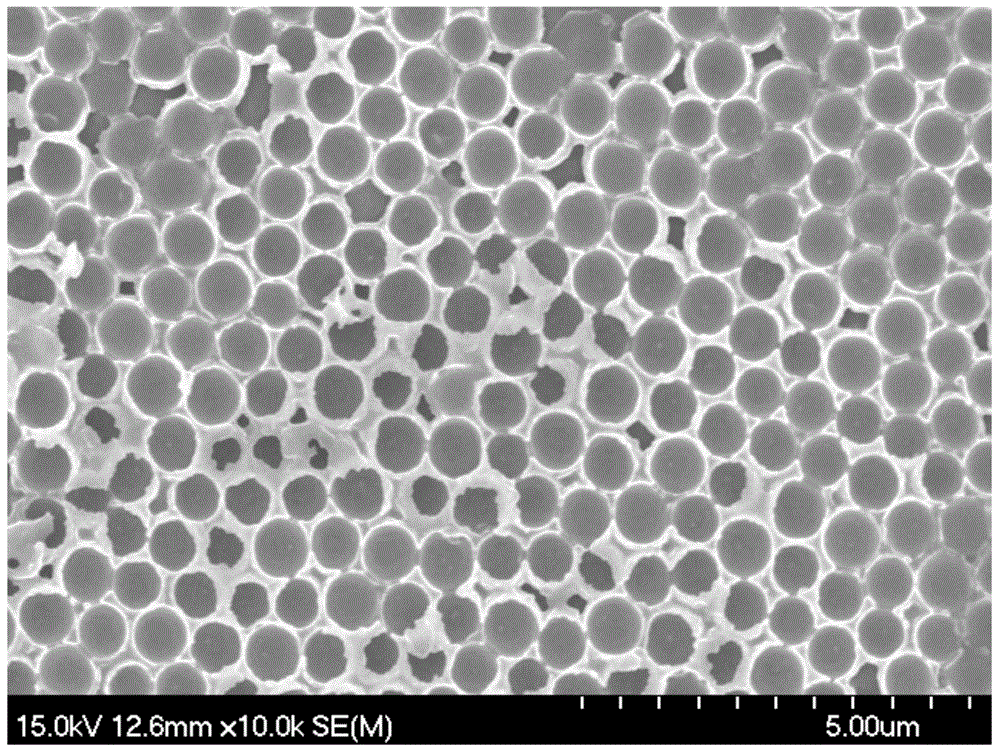

[0054] (1) Preparation of polystyrene microsphere monolayer template: ITO glass with an area of 2 cm × 4 cm was ultrasonically cleaned and dried, and a small amount of polystyrene microspheres (2.5% w / v, microsphere pore size 600 nm ) evenly spread a layer on the ITO glass (reserve the area for clamping the clip in the subsequent test), then place it horizontally for 30-40s, then slowly tilt it to a vertical state, and then place it on the bottom of the ITO glass for 10-20s Put it into a petri dish filled with deionized water, and the excess polystyrene microspheres will quickly disperse in the deionized water, and finally pull it out of the water surface to dry vertically to obtain a single self-assembled polystyrene microsphere. Layer template, and its scanning electron microscope (SEM) test ( figure 1 , as shown in 2).

[0055] (2) Prepara...

Embodiment 2

[0057] The monomer is 1,4-bis(3-thiophene)benzene, and its structure is as follows:

[0058]

[0059] The electrolyte solution and the blank solution are the same as in Example 1, and the polymerization electric quantity becomes 0.035C.

[0060] Operation process:

[0061] (1) Preparation of polystyrene microsphere monolayer template: ITO glass with an area of 2 cm × 4 cm was ultrasonically cleaned and dried, and a small amount of polystyrene microspheres (2.5% w / v, microsphere pore size 600 nm ) evenly spread on the ITO glass (reserve the area used for clamping the clip in the subsequent test), then place it horizontally for 30-40s, then slowly tilt it to a vertical state, and then put the bottom of the ITO glass into it after 10-20s In the petri dish filled with deionized water, the excess polystyrene microspheres will be quickly dispersed in deionized water, and finally pulled out of the water surface to dry vertically to obtain a single-layer template composed of pol...

Embodiment 3

[0064] The monomer is (three (4-(2-thiophene)) triphenylamine), and its structure is as follows:

[0065]

[0066] The electrolyte solution and the blank solution were the same as in Example 1, except that the microspheres were changed to polystyrene microspheres with amino groups (600-1000nm 2.5% w / v).

[0067] Operation process:

[0068] (1) Preparation of aminopolystyrene microsphere monolayer template: ultrasonically clean the ITO glass with an area of 2cm×4cm and dry it, and take a small amount of aminopolystyrene microspheres (2.5% w / v, 600nm) with a dropper Evenly spread it on the ITO glass (reserve the area for clamping the clip in the follow-up test), then place it horizontally for 30-40 seconds, then slowly tilt it to a vertical state, and then put the bottom of the ITO glass into the container after 10-20 seconds. In the petri dish with deionized water, the excess aminopolystyrene microspheres will be quickly dispersed in deionized water, and finally pulled ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com