Sealing gasket of transformer and preparation method thereof

A technology for gaskets and transformers, applied in the field of transformer parts, can solve problems such as easy aging, economic losses of power systems and users, and oil leakage from transformers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

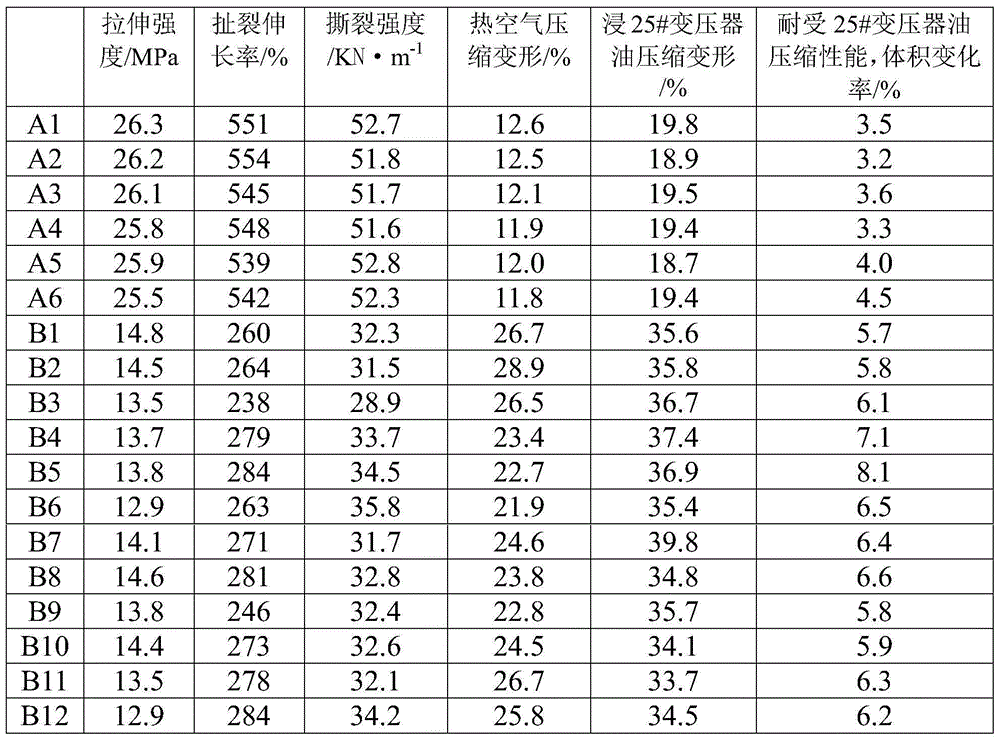

Examples

preparation example Construction

[0013] The present invention provides a kind of preparation method of transformer gasket, and described preparation method comprises:

[0014] a. At 125-135°C, knead epichlorohydrin rubber, carbon black, silicone rubber, epoxy butyl stearate and expanded vermiculite to obtain the first mixture;

[0015] b. Add magnesium chloride, zinc stearate, nano-titanium dioxide, accelerator and anti-aging agent to the first mixture at 90-100°C and knead to obtain the second mixture;

[0016] c. kneading the second mixture and vulcanizing agent at 170-190° C. to perform vulcanization treatment to obtain a transformer gasket;

[0017] Wherein, relative to 100 parts by weight of the chlorohydrin rubber, the consumption of the carbon black is 7-11 parts by weight, the consumption of the silicone rubber is 40-60 parts by weight, and the consumption of the epoxy butyl stearate is 20-25 parts by weight, the consumption of the expanded vermiculite is 8-12 parts by weight, the consumption of the ...

Embodiment 1

[0031] a. At 130°C, mix 100kg of chlorohydrin rubber, 9kg of carbon black, 50kg of silicone rubber, 22kg of epoxy butyl stearate and 10kg of expanded vermiculite for 1.5 hours to obtain the first mixture; After heat treatment at 220°C for 2.5 hours and grinding, the particle size of expanded vermiculite is 1 mm; the weight average molecular weight of epichlorohydrin rubber is 70,000; the weight average molecular weight of silicone rubber is 40,000.

[0032] b. At 95°C, 3.5 kg of magnesium chloride, 20 kg of zinc stearate, 1 kg of nano-titanium dioxide, 1.3 kg of N-tert-butyl bis-2-benzothiazole sulfenic acid amine and 2,2,4-trimethyl - 0.8 kg of 1,2-dihydroquinoline was added to the first mixture and kneaded for 10 hours to prepare the second mixture; wherein, the particle size of the nano-titanium dioxide was 8 nm.

[0033] c. Knead the second mixture and 4 kg of tetraethylthiuram disulfide at 180° C. for 6 hours to perform vulcanization treatment to obtain transformer gasket...

Embodiment 2

[0036] a. At 125°C, mix 100kg of chlorohydrin rubber, 7kg of carbon black, 40kg of silicone rubber, 20kg of epoxy butyl stearate and 8kg of expanded vermiculite for 1 hour to obtain the first mixture; After heat treatment at 200°C for 2 hours and grinding, the particle size of expanded vermiculite is 0.5 mm; the weight average molecular weight of epichlorohydrin rubber is 50,000; the weight average molecular weight of silicone rubber is 20,000.

[0037] b. At 90°C, 3 kg of magnesium chloride, 15 kg of zinc stearate, 0.5 kg of nano-titanium dioxide, 1.2 kg of N-tert-butyl bis-2-benzothiazole sulfenic acid amine and 2,2,4-trimethyl - 0.5 kg of 1,2-dihydroquinoline was added to the first mixture and kneaded for 8 hours to prepare the second mixture; wherein, the particle size of nano-titanium dioxide was 5 nm.

[0038] c. Knead the second mixture and 3 kg of tetraethylthiuram disulfide at 170° C. for 5 hours to perform vulcanization treatment to obtain transformer gasket A2.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com