Metallic cathode electrophoretic paint and preparation method thereof

A technology for electrophoretic coatings and metal cathodes, applied in electrophoretic coatings, coatings, etc., can solve problems such as poor adhesion of paint films, achieve low curing temperature, improve binding ability, and enhance acid resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

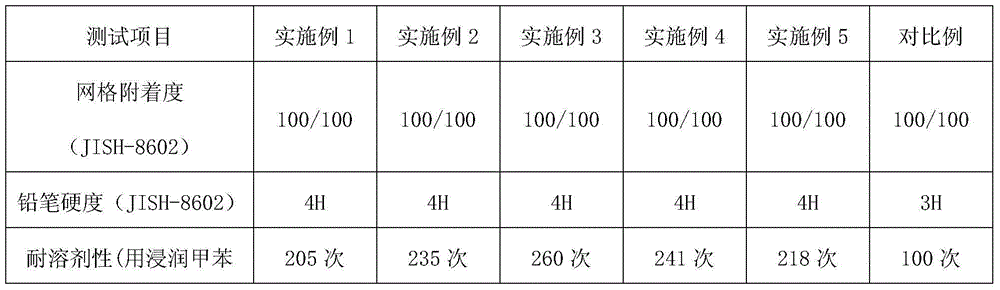

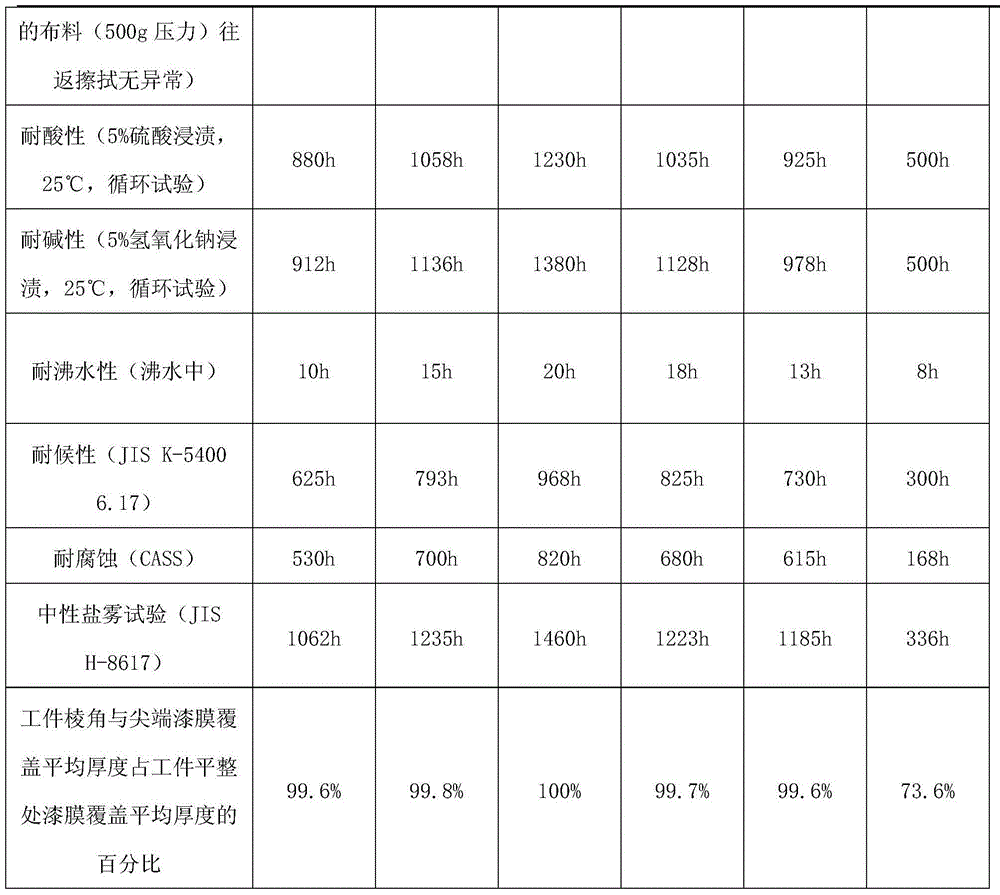

Examples

Embodiment 1

[0038] A metal cathodic electrophoretic coating, comprising: 20 parts of modified epoxy resins, 0.5 parts of methyltrimethoxysilane, 2 parts of hydroxypropyl cellulose acetate, and 5 parts of ethyl 2-cyanoacrylate by weight components , 0.8 part of acrylamide, 0.6 part of 2-acrylamido-2-methylpropanesulfonic acid, 1 part of hypromellose, 0.8 part of zinc stearate; wherein the formula of the modified epoxy resin is expressed in weight units The components include: 10 parts of epoxy resin, 4 parts of alkylphenol polyoxyethylene ether, 2 parts of toluene diisocyanate, 1 part of azobisisobutyronitrile, and 2 parts of maleic anhydride.

[0039] The particle size of the above zinc stearate was 100 μm.

[0040] (1) The preparation method of above modified epoxy resin is:

[0041] Step 1, adding epoxy resin to the reaction kettle, adding alkylphenol polyoxyethylene ether and azobisisobutyronitrile, stirring and mixing evenly, wherein the condition of stirring and mixing is that the s...

Embodiment 2

[0048] A metal cathodic electrophoretic coating, comprising: 25 parts of modified epoxy resins, 0.8 parts of methyltrimethoxysilane, 5 parts of hydroxypropyl cellulose acetate, and 8 parts of ethyl 2-cyanoacrylate by weight components , 1.2 parts of acrylamide, 1 part of 2-acrylamido-2-methylpropanesulfonic acid, 2 parts of hypromellose, 2 parts of zinc stearate; wherein the formula of the modified epoxy resin is expressed by weight The components include: 14 parts of epoxy resin, 5 parts of alkylphenol polyoxyethylene ether, 4 parts of toluene diisocyanate, 2 parts of azobisisobutyronitrile, and 3 parts of maleic anhydride.

[0049] The particle size of the above zinc stearate was 120 μm.

[0050] (1) The preparation method of above modified epoxy resin is:

[0051] Step 1, adding epoxy resin to the reaction kettle, adding alkylphenol polyoxyethylene ether and azobisisobutyronitrile, stirring and mixing evenly, wherein the conditions of stirring and mixing are stirring at a ...

Embodiment 3

[0058] A metal cathodic electrophoretic coating, comprising by weight components: 27 parts of modified epoxy resin, 1 part of methyltrimethoxysilane, 6 parts of hydroxypropyl cellulose acetate, 9 parts of ethyl 2-cyanoacrylate , 1.5 parts of acrylamide, 1.2 parts of 2-acrylamido-2-methylpropanesulfonic acid, 3 parts of hypromellose, 2.3 parts of zinc stearate; wherein the formula of the modified epoxy resin is expressed by weight The components include: 16 parts of epoxy resin, 6 parts of alkylphenol polyoxyethylene ether, 5 parts of toluene diisocyanate, 3 parts of azobisisobutyronitrile, and 4 parts of maleic anhydride.

[0059] The particle size of the above zinc stearate was 150 μm.

[0060] (1) The preparation method of above modified epoxy resin is:

[0061] Step 1: Add epoxy resin to the reaction kettle, add alkylphenol polyoxyethylene ether and azobisisobutyronitrile, stir and mix evenly, wherein the condition of stirring and mixing is that the stirring speed is 110 r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid resistance | aaaaa | aaaaa |

| alkali resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com