Waste copper pretreating and refining technology

A pretreatment and refining technology, applied in the direction of improving process efficiency, can solve problems such as harm to workers' health, difficulties, loss of valuable components of metal copper, etc., and achieve the effects of speeding up the smelting time, improving the utilization rate, and improving the purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

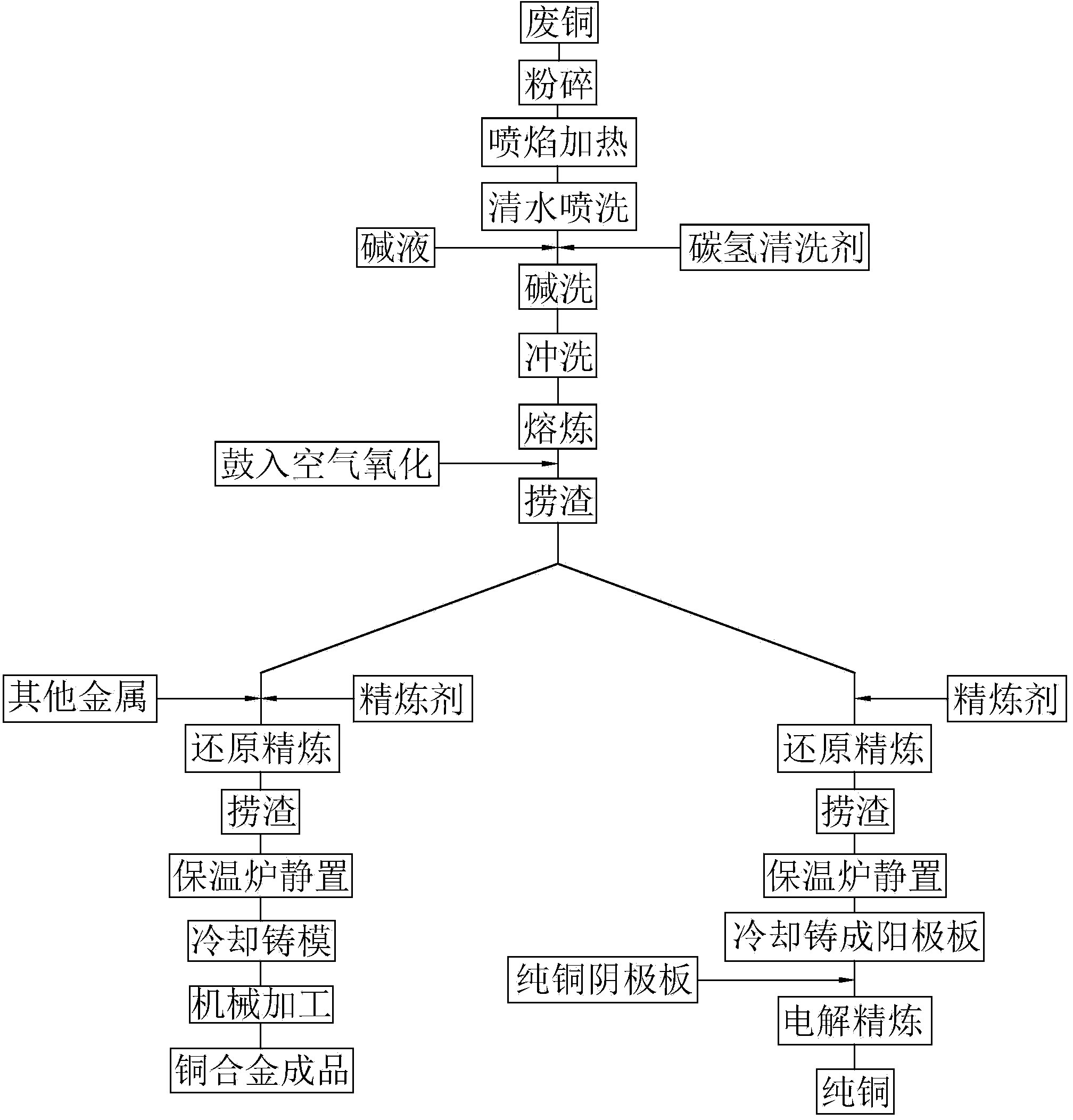

[0037] refer to figure 1 The embodiment of the waste copper pretreatment and refining process of the present invention will be further described.

[0038] like figure 1 As shown, a copper scrap pretreatment and refining process, the copper scrap pretreatment process steps are as follows:

[0039] ①Material selection and crushing: Select scrap copper according to the finished product to be prepared, put the scrap copper into a crusher for crushing, and screen and distinguish scrap copper from impurities such as plastics;

[0040] ②Flame heating: Perform high-temperature flame surface heating treatment on the pulverized waste copper fragments, the heating temperature is controlled at 600-900°C, and heated for 3 minutes;

[0041] ③Water spray washing: Use a high-pressure water gun to clean the high-temperature waste copper fragments;

[0042] ④ Alkali washing: The cleaned copper scraps are soaked in lye. The lye includes alkaline substances and hydrocarbon cleaning agents. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com