Damp-proof corrosion-resistant inflaming-retarding electric power communication cable

A power communication and corrosion-resistant technology, which is applied in the direction of power cables with shielding layers/conductive layers, insulated cables, twisted/quad-stranded cables, etc., can solve the problem of moisture-proof and corrosion-resistant effects , reduced working life of cables, unstable power transmission and other problems, to achieve good softness and elasticity, long service life and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

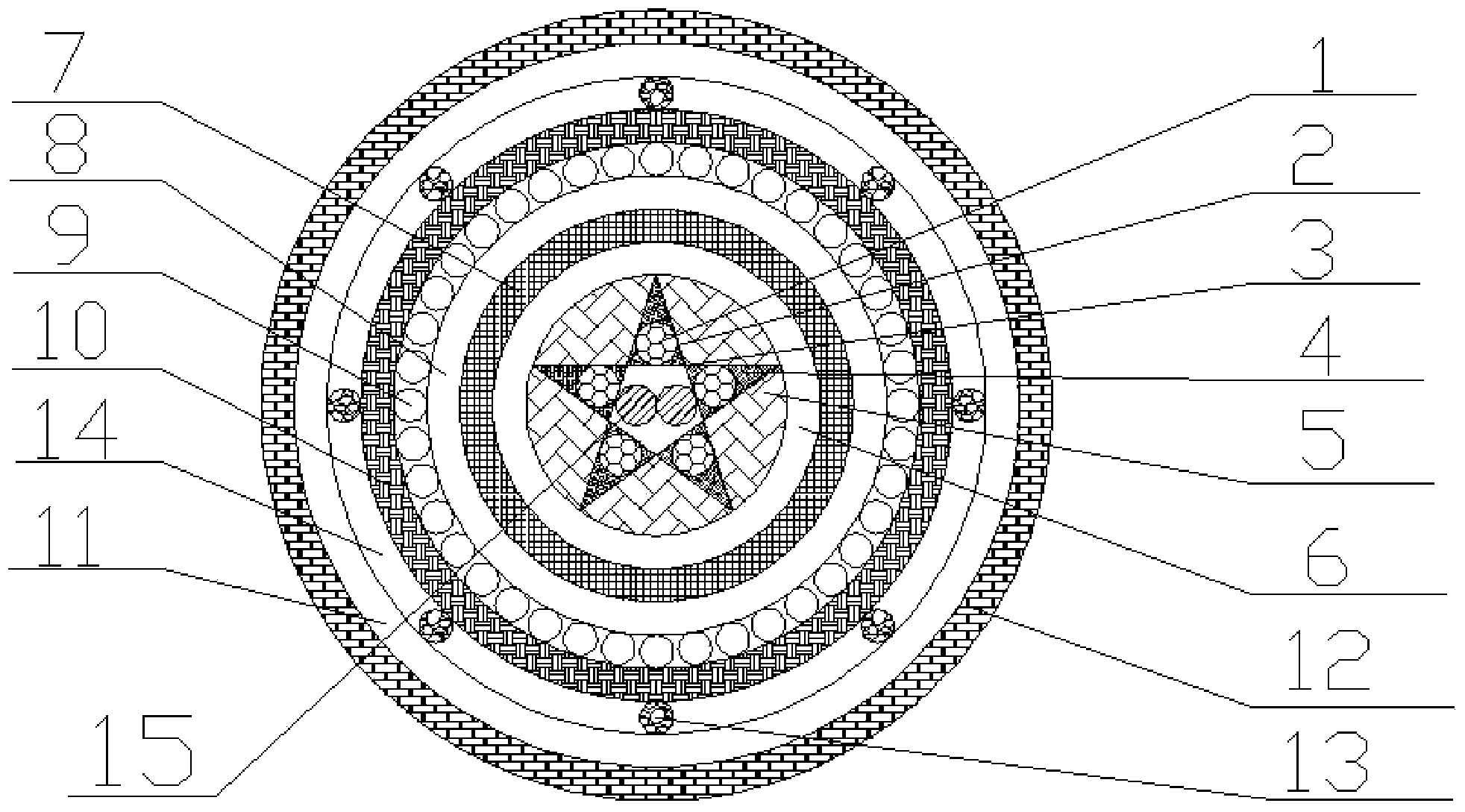

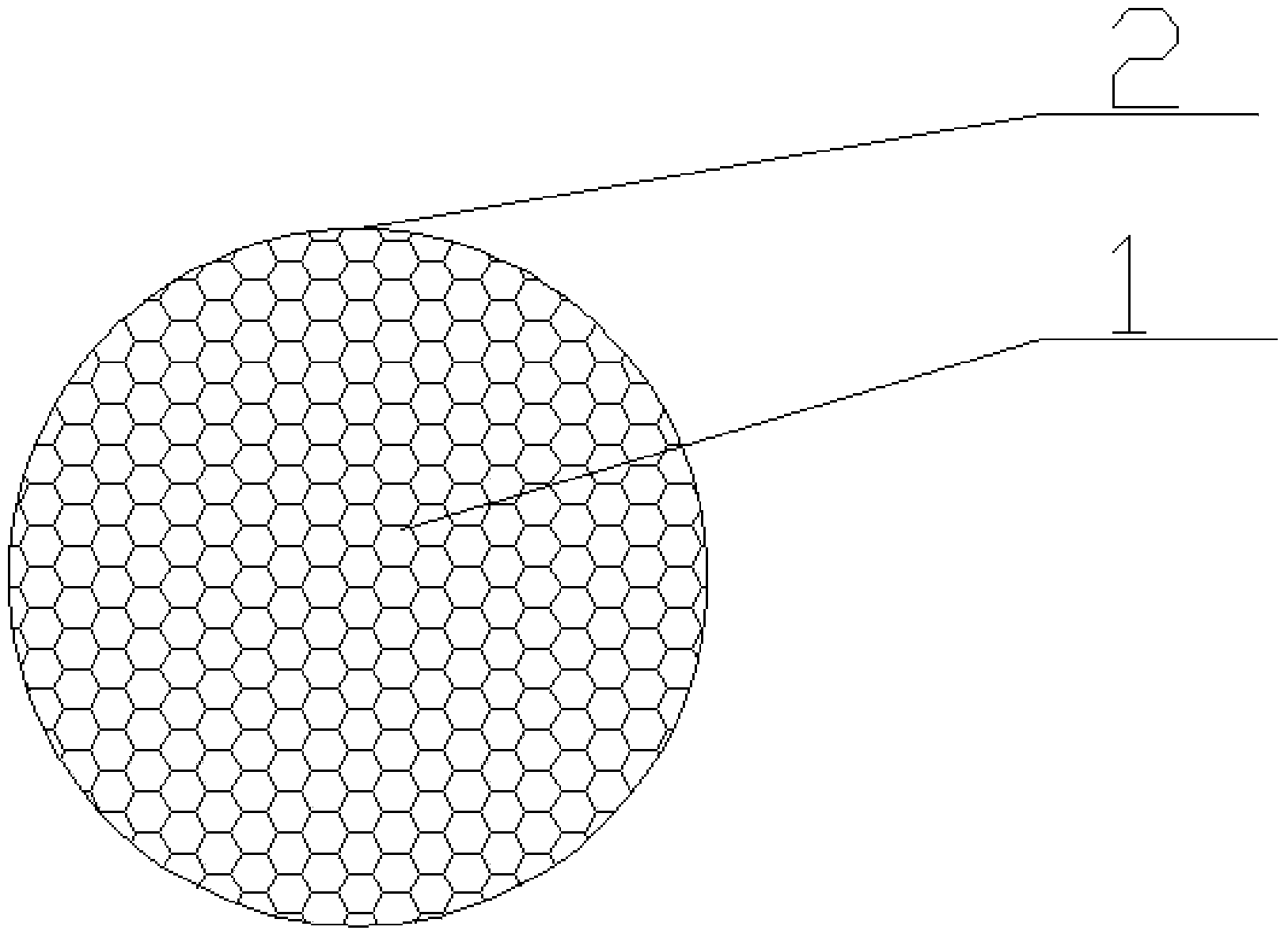

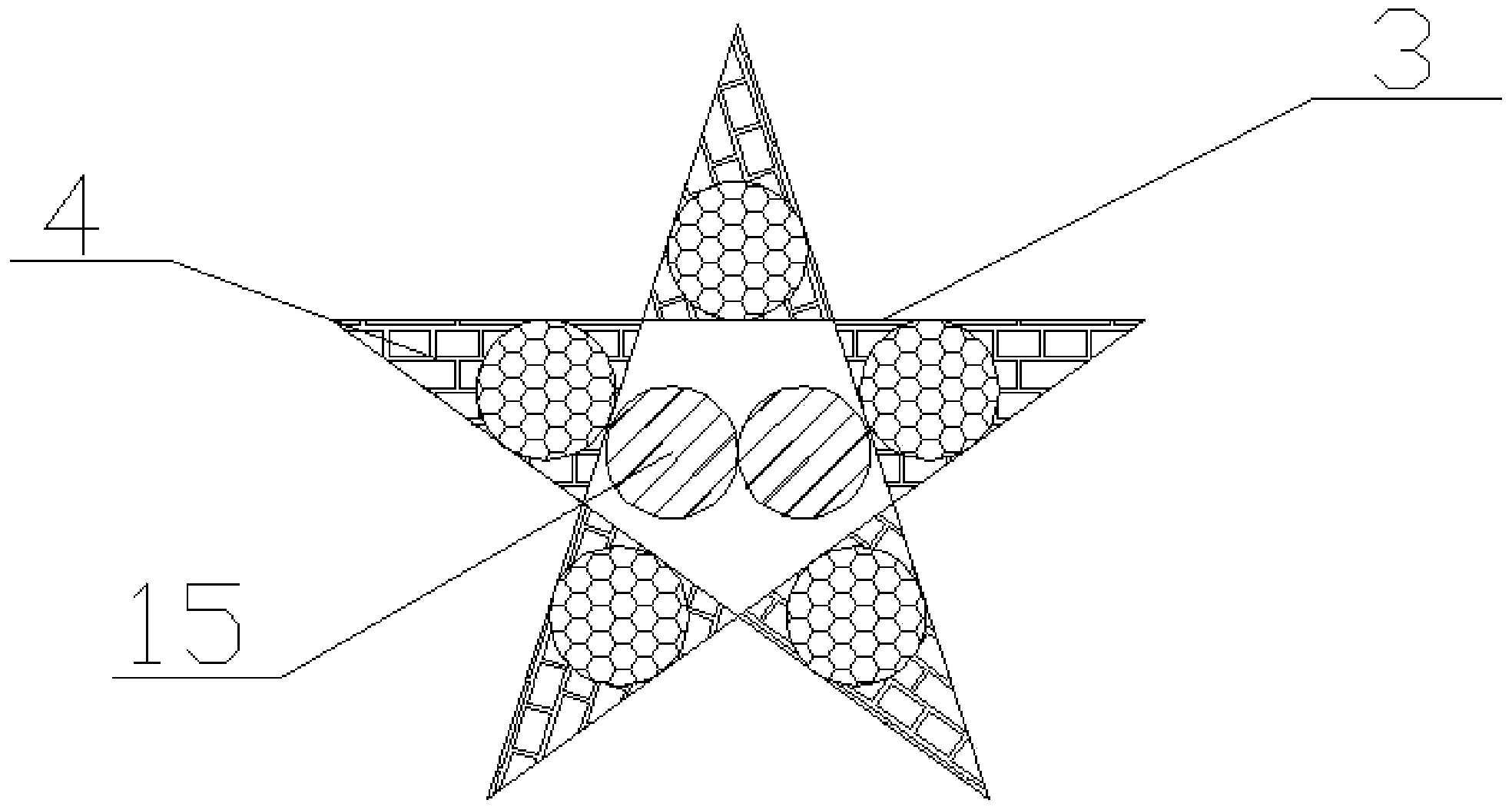

[0026] Such as Figures 1 to 3 As shown, the first specific embodiment of the present invention is: a moisture-proof, corrosion-resistant and flame-retardant power communication cable, which includes a conductor 2 and an insulating layer 6, and the cross-section of the conductor 2 is a circular structure; the conductor 2 A plurality of wire cores 1 are arranged inside; and the conductor 2 is arranged in the PVC plastic connecting rod 3; the gap between the PVC plastic connecting rod 3 and the conductor 2 is provided with a water-blocking filling layer 4; the PVC plastic connecting rod 3. There are two aluminum alloy hoses 15 arranged in the center; the PVC plastic connecting rod 3 is extruded with a layer of insulating layer 6; the gap between the insulating layer 6 and the PVC plastic connecting rod 3 is provided with a filler 5; The insulating layer 6 is tightly extruded with a layer of shielding layer 7; the shielding layer 7 is tightly extruded from the inside to the outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com