A Multilayer Power Distribution Network Based on High Frequency Printed Board with Resistive Film

A technology of power distribution network and distribution network, which is applied in the direction of circuits, electrical components, printed circuit components, etc., and can solve problems such as low quality reliability, poor channel consistency, and large assembly workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

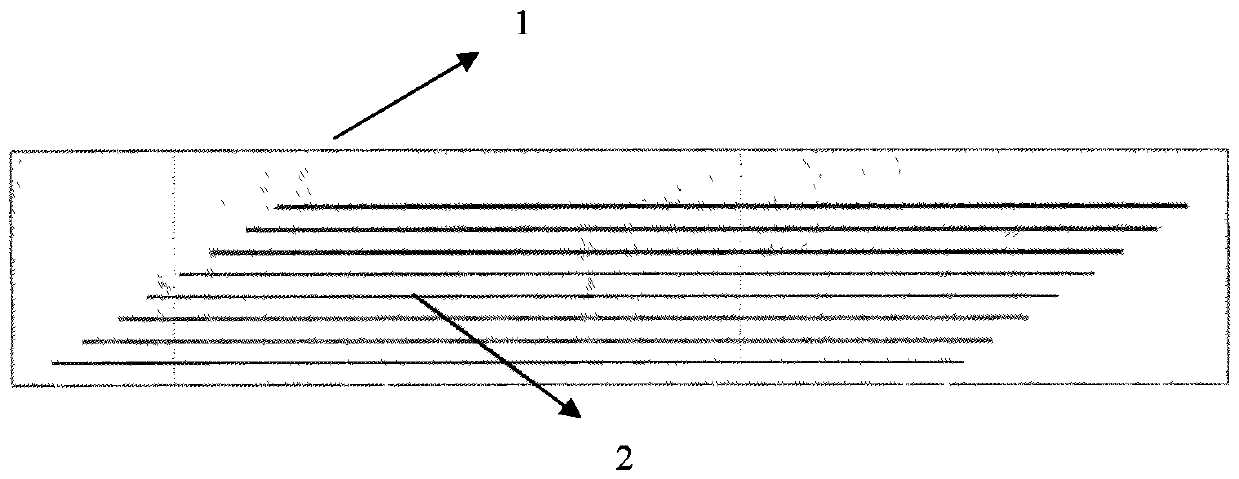

[0015] The invention provides a multilayer power distribution network based on a high-frequency printed board with a resistive film, a multilayer power distribution network based on a copper clad board with a resistive film, and each layer of the multilayer power distribution network is set as a Stripline structure, the lower medium of the stripline structure is a core board, and the upper medium of the stripline structure is a prepreg; the multi-layer power distribution network is provided with ladder slots to lead out signal lines, so as to facilitate communication with other circuits Interconnection: use the printed board multi-layer mixed voltage process to integrate the power division network with other circuits.

[0016] In the above, the core plate is a high-frequency plate with a built-in resistive film and a small loss angle; the prepreg is a high-frequency plate with a small loss angle; the core plate and the prepreg have the same dielectric constant.

[0017] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com