A kind of lotus seed enzyme

A technology of lotus seeds and enzymes, applied in the functions of food ingredients, food science, applications, etc., can solve the problems that the value of by-products of distiller's grains has not been deeply excavated, the value of distiller's grains has not been deeply excavated, and lotus seed enzyme products have not been seen, and achieve the benefits of The effect of sustainable development, enriching the enzyme market, and improving the utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Lotus seed distiller's grains of the present invention comes from the preparation technology of following scheme:

[0041] Cooked rice husk: Steam the rice husk with dry hot steam for more than 120 minutes until the aroma is released, then take it out of the retort and cool it down.

[0042] plan 1:

[0043] A. Requirements for brewing water and lotus seeds: the brewing water should be colorless, odorless and sterile, and the iron content should be less than 0.02ppm; the lotus seeds should be plump, round, white and clean, with lotus heart, moisture content below 14%, and no mildew , no insects, no impurities.

[0044] B. Broken lotus seeds: The lotus seeds are crushed into 2-4 petals with a double-roll mill, and no fine powder is required.

[0045] C. Soaking: soak the broken lotus seeds with the brewing water of step A at low temperature, the water temperature is 10°C, and the soaking time is 10 hours.

[0046] D. Cooking and gelatinization: the lotus seeds soaked ...

Embodiment 1

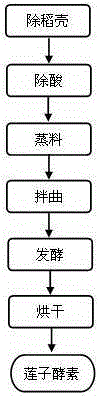

[0071] Such as figure 1 A kind of lotus seed ferment shown is prepared by the following steps:

[0072] (1) Rice husk removal: Wash the lotus seed distiller's grains with clean water to remove the rice husk.

[0073] (2) Deacidification: The lotus seed distiller's grains obtained in step (1) were soaked in water for 12 hours to deacidify.

[0074] (3) Steaming: Steam the lotus seed distiller's grains obtained in step (2) for 60 minutes with dry hot steam at 100°C.

[0075] (4) Mixing koji: Cool the lotus seed distiller's grains obtained in step (3) to 20°C, and then mix the koji. 3.042 Aspergillus oryzae strains), the consumption of Rhizopus Q303 is 0.5% of the weight of lotus seed distiller's grains, and the consumption of Aspergillus oryzae is 0.05% of the weight of lotus seed distiller's grains.

[0076] (5) Fermentation: Evenly spray alcohol with an alcohol content of 40° on the surface of the lotus seed distiller's grains obtained in step (4), the amount of alcohol is ...

Embodiment 2

[0079] Such as figure 1 A kind of lotus seed ferment shown is prepared by the following steps:

[0080] (1) Rice husk removal: Wash the lotus seed distiller's grains with clean water to remove the rice husk.

[0081] (2) Deacidification: The lotus seed distiller's grains obtained in step (1) were soaked in water for 48 hours to deacidify.

[0082] (3) Steaming material: Mix the lotus seed distiller's grains obtained in step (2) with rice flour and steam the material with dry hot steam at 120°C for 20 minutes, and the amount of rice flour is 30% of the weight of lotus seed distiller's grains.

[0083] (4) Mixing koji: Cool the lotus seed distiller's grains obtained in step (3) to 40°C, and then mix the koji. 3.042 Aspergillus oryzae strains), the consumption of Rhizopus Q303 is 1.5% of the weight of lotus seed distiller's grains, and the consumption of Aspergillus oryzae is 0.03% of the weight of lotus seed distiller's grains.

[0084] (5) Fermentation: Evenly spray alcohol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com