Medical titanium metal material and preparation method thereof

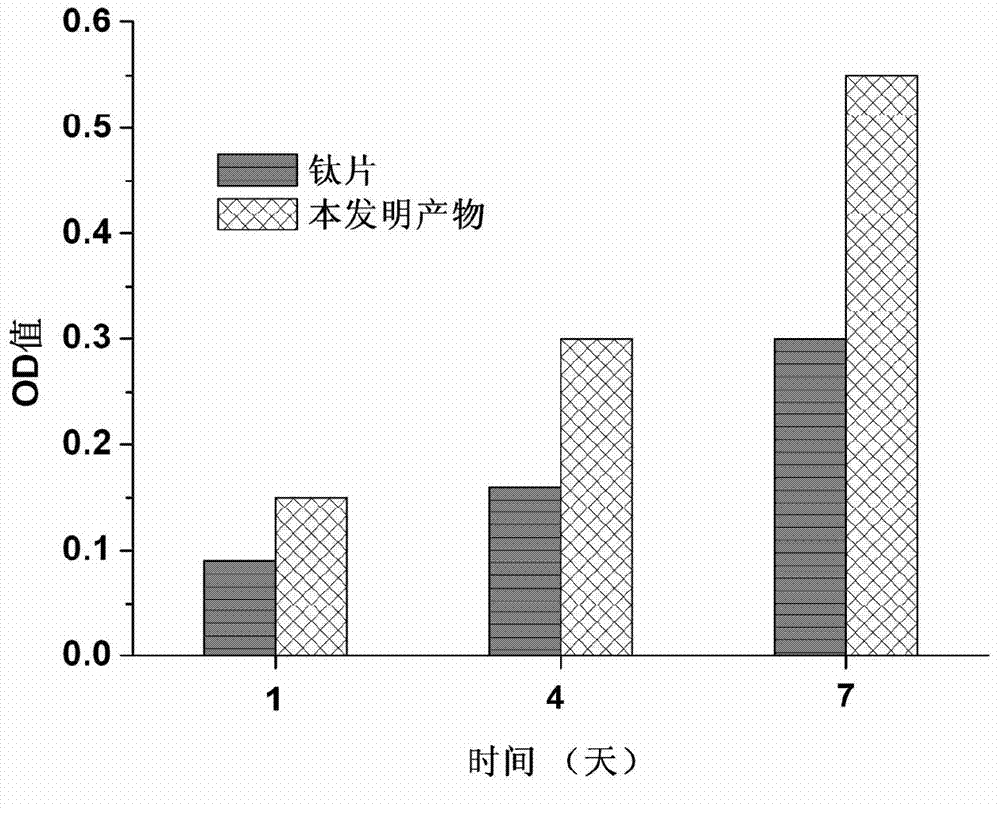

A technology of titanium metal and adhesion layer, which is applied in the field of surface modification of biomedical materials, can solve the problems of not being able to provide fixation and growth of osteoblasts, and achieve the goal of avoiding adhesion and reproduction, preventing shedding, and improving anti-bacterial adhesion ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a medical titanium metal material, wherein the method comprises the following steps:

[0041]Step 1. Pretreatment: The surface of the titanium sheet was sequentially polished with silicon carbide sandpaper No. 600 to No. 1200, and then ultrasonicated with acetone, ethanol and distilled water for 30 minutes in sequence, and vacuum-dried at 80°C to obtain the processed product 1;

[0042] Step 2. Preparation of titanium metal nanotubes: In the anodic oxidation electrolyte, connect the product 1 to the anode of the power supply, use a platinum sheet electrode as the cathode, and slowly increase the anodic oxidation voltage to the final voltage at a rate of 1V / s. During the oxidation process The electrolyte has been electromagnetically stirred, and after the anodic oxidation treatment is completed, it is immediately rinsed with a large amount of distilled water and dried to obtain product 2, which is a titanium metal matrix with a nanotube structure fo...

Embodiment 1

[0051] 1. Product preparation

[0052] The surface of the titanium sheet was sequentially polished with silicon carbide sandpaper No. 600 to No. 1200, and then ultrasonicated with acetone, ethanol and distilled water for 30 minutes, and vacuum-dried at 80°C to obtain the processed product 1; in the anodic oxidation electrolyte, the product 1 was connected to To the anode of the power supply, the cathode uses a platinum sheet electrode, and the anodizing voltage is slowly increased to the final voltage at a rate of 1V / s. During the oxidation process, the electrolyte has been electromagnetically stirred. Product 2 was obtained; then product 2 was soaked in 5mmol 3-(trifluoromethyl) benzyl mercaptan, soaked for 24 hours, washed with distilled water, and dried to obtain product 3; Glycol methyl ether ester, 0.19 mmol polyethylene glycol methacrylate with a molecular weight of 600, 5 mmol CuCl 2 Add 30ml of water and 15ml of ethanol, stir evenly, add 1~5mL with a density of 2×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com