Flower-shaped MoS2 loaded Ag3PO4 nanosphere composite visible light catalyst and preparation method thereof

A nanosphere, visible light technology, applied in the field of photocatalytic materials, can solve the problems of being relatively expensive, prone to self-corrosion, instability, etc., and achieve the effects of simple steps, excellent visible light catalytic performance, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Weigh 0.892g of Zn(NO 3 ) 2 ·6H 2 O. 0.228g of thiourea, 60ml of ethylenediamine and 4ml of deionized water were heated at 150°C for 12 hours to obtain a sheet-shaped ZnS material, which was ready for use.

[0038] 2) Mix the material obtained in 1) with a mixed aqueous solution (60mL) of 0.5mmol ammonium molybdate and 3.7mmol thioacetamide, and then heat at 180°C for 12h to obtain ZnS-ethylenediamine-MoS 2 hybrid materials.

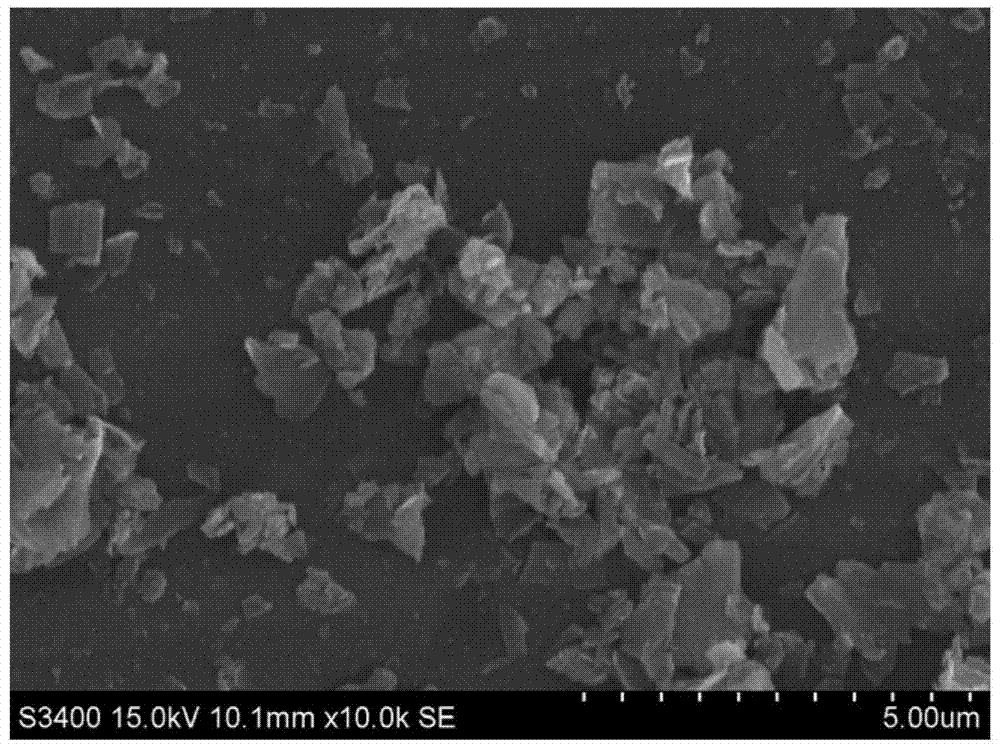

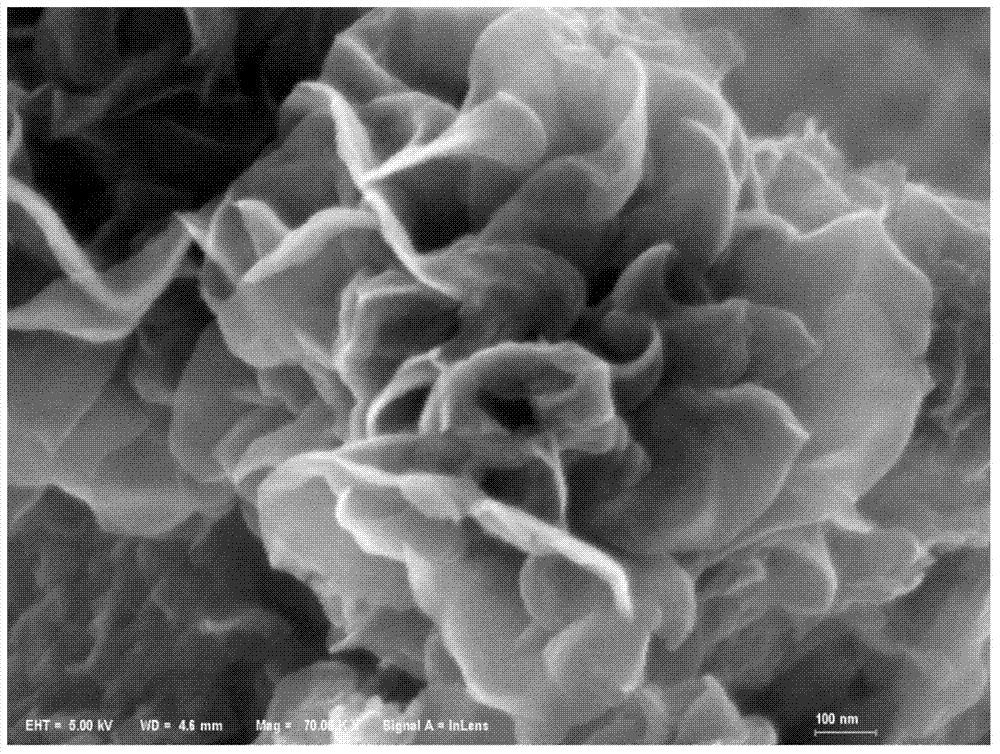

[0039] 3) Add 1M dilute hydrochloric acid solution to the hybrid material in 2), react for 8 hours, wash with centrifuge, and dry at 60°C to obtain black flower-like MoS 2 Material.

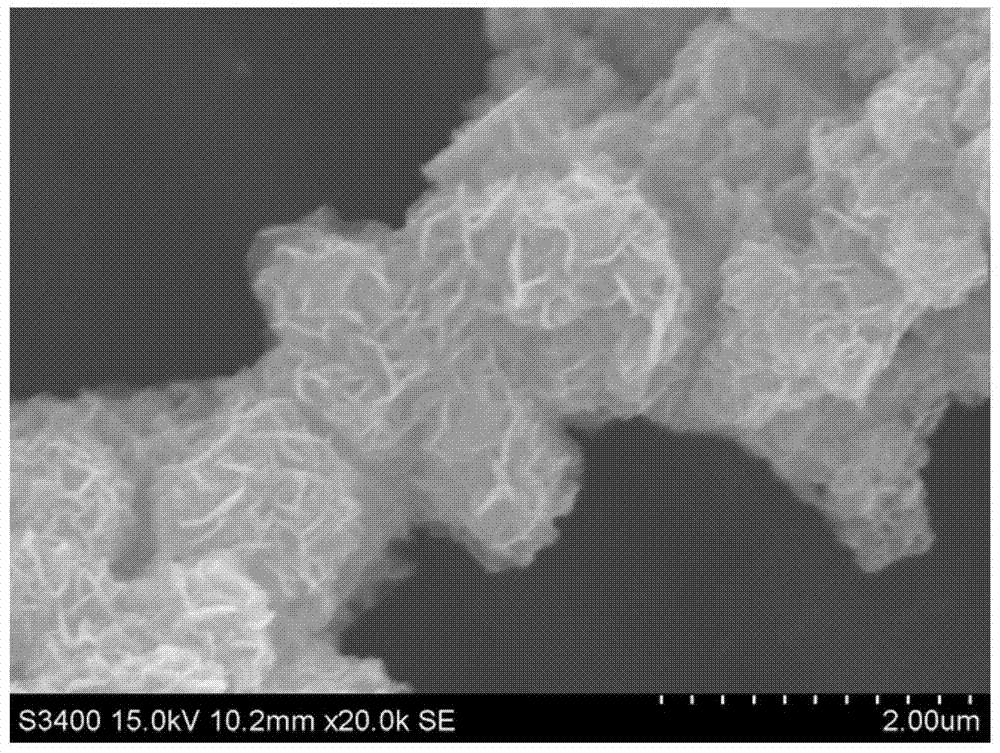

[0040] 4) Configure 0.0375M AgNO at room temperature and avoid light 3 aqueous solution (40mL), to which was added the MoS obtained in step 3)2 Material (0.005g), stirred for 30min. Then, under magnetic stirring, 5ml of 0.1M Na was added dropwise 3 PO 4 solution, a light yellow turbid liquid was obtained, which gradually turned yellow-green. After the dro...

Embodiment 2

[0047] 1) Weigh 0.446g of Zn(NO 3 ) 2 , 0.114g of thiourea, 60ml of ethylenediamine and 4ml of deionized water, and heated at 150°C for 12h to obtain a sheet-shaped ZnS material, which is ready for use.

[0048] 2) Mix the material obtained in 1) with a mixed aqueous solution (60mL) of 0.2mmol ammonium molybdate and 1.5mmol thioacetamide, and heat at 180°C for 12h to obtain ZnS-ethylenediamine-MoS 2 hybrid materials.

[0049] 3) Add 1M dilute hydrochloric acid solution to the hybrid material in 2), react for 8 hours, wash with centrifuge, and dry at 60°C to obtain black flower-like MoS 2 Material.

[0050] 4) Configure 0.0375M AgNO at room temperature and avoid light 3 aqueous solution (40mL), to which was added the MoS obtained in step 3) 2 Material (0.01 g), stirred for 30 min. Then, under magnetic stirring, 5ml of 0.1M Na was added dropwise 3 PO 4 solution, a light yellow turbid liquid was obtained, which gradually turned yellow-green. After the dropwise addition, ...

Embodiment 3

[0052] 1) Weigh 0.892g of Zn(NO 3 ) 2 , 0.228g of thiourea, 60ml of ethylenediamine and 4ml of deionized water, and hydrothermally heated at 150°C for 12h to obtain flaky ZnS material, which is ready for use.

[0053] 2) Mix the material obtained in 1) with a mixed aqueous solution (60mL) of 0.3mmol ammonium molybdate and 2.2mmol thioacetamide, and then heat at 180°C for 12h to obtain ZnS-ethylenediamine-MoS 2 hybrid materials.

[0054] 3) Add 1M dilute hydrochloric acid solution to the hybrid material in 2), react for 8 hours, wash with centrifuge, and dry at 60°C to obtain black flower-like MoS 2 Material.

[0055] 4) Configure 0.0375M AgNO at room temperature and avoid light 3 aqueous solution (40mL), to which was added the MoS obtained in step 3) 2 Material (0.02g), stirred for 30min. Then, under magnetic stirring, 5ml of 0.1M Na was added dropwise 3 PO 4 solution, a light yellow turbid liquid was obtained, which gradually turned yellow-green. After the dropwise a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com