Cold laid bituminous mixture for roads and manufacturing method and construction technology thereof

A technology of cold-laying asphalt and construction technology, which is applied in the construction technology field of road repair and maintenance, and can solve problems such as poor bonding performance, repair failure, and impossibility of pothole repair in important road sections, and achieve the effect of fast construction and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0066] The composition of the road cold paving asphalt mixture of the present invention and the content thereof in parts by weight are as follows: weight unit is: kg

[0067]

[0068] The manufacture method and construction technology of road cold paved asphalt mixture of the present invention are as follows:

[0069] 1. When the base asphalt (road petroleum asphalt) is heated to 120°C, add petroleum resin and stir until the additives are completely melted to obtain modified asphalt;

[0070] 2. When the modified asphalt is cooled to 100°C, add No. 0 diesel oil to prepare cold paving asphalt binder;

[0071] 3. Mix the above-mentioned cold paved asphalt binder with mineral materials at a temperature of 80-100 °C to prepare a cold paved asphalt mixture;

[0072] 4. Before storing the stored cold asphalt mixture after mixing, it should be paved and cooled in a thin layer on a clean site in advance. When the temperature of the mixture drops to room temperature, it can be stor...

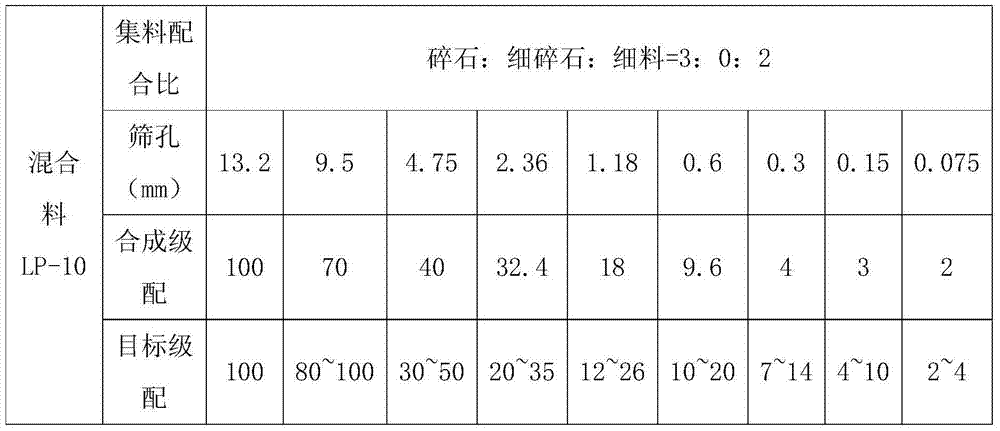

Embodiment 5

[0080] Take 1.8 tons of petroleum resin, 9.8 tons of No. 0 diesel oil, 35 tons of road petroleum asphalt, and 960 tons of mineral materials. (The coarse aggregate is made of crushed stone rolled from diabase, and the mineral powder is made of finely ground limestone. The gradation has been discussed above.) When the road petroleum asphalt (matrix asphalt) is heated to 120°C, put Add petroleum resin and stir until the road petroleum asphalt is completely melted to obtain modified asphalt; when the modified asphalt is cooled to 100°C, add No. 15% of the weight of road petroleum asphalt; continue to cool to 80-90 ° C, mix the above-mentioned cold-paved asphalt binder with mineral materials, and make the cold-paved asphalt mixture of the present invention.

[0081] When the cold paving mixture prepared in this embodiment is used for asphalt pavement potholes and cement pavement potholes for repairing, the potholes should be treated in advance, and there should be stable side limit...

Embodiment 6

[0083] Take 2.5 tons of petroleum resin, 7.8 tons of No. 0 diesel oil, 55 tons of road petroleum asphalt, and 930 tons of mineral materials. (The coarse aggregate is made of crushed stone rolled from diabase, and the mineral powder is made of finely ground limestone. The gradation has been discussed above.) When the road petroleum asphalt (matrix asphalt) is heated to 120°C, put Add petroleum resin and stir until the road petroleum asphalt is completely melted to obtain modified asphalt; when the modified asphalt is cooled to 100°C, add No. 17% of the weight of road petroleum asphalt; continue to cool to 80-90 ° C, mix the above-mentioned cold-paved asphalt binder with mineral materials, and make the cold-paved asphalt mixture of the present invention.

[0084] When the cold paving mixture prepared in this embodiment is used for asphalt pavement potholes and cement pavement potholes for repairing, the potholes should be treated in advance, and there should be stable side limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com