Bromine base fire retardation agent and preparation method thereof

A brominated flame retardant and technology of flame retardants, applied in the field of flame retardants, can solve problems such as unsatisfactory effects of brominated flame retardants, achieve good flame retardancy and practicability, better effect and less addition amount Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

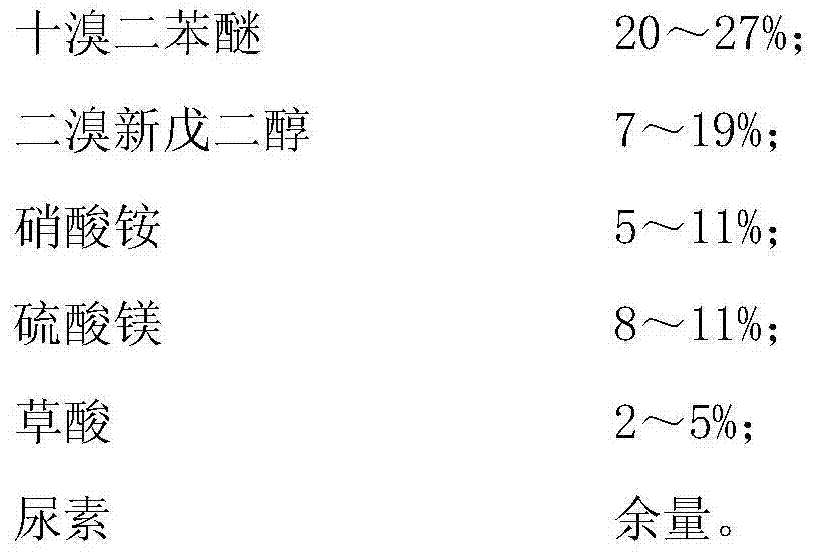

[0015] Components and their weight ratios: 20% decabromodiphenyl ether, 19% dibromoneopentyl glycol; 11% ammonium nitrate; 8% magnesium sulfate; 5% oxalic acid, 37% urea.

[0016] Preparation method: Mix the above components into a blender, add water until submerged, and stir at 50°C for 2 hours.

Embodiment 2

[0018] Components and their weight ratios: 27% decabromodiphenyl ether, 7% dibromoneopentyl glycol; 5% ammonium nitrate; 11% magnesium sulfate; 2% oxalic acid, 48% urea.

[0019] Preparation method: Mix the above components into a blender, add water until submerged, and stir at 40°C for 4 hours.

Embodiment 3

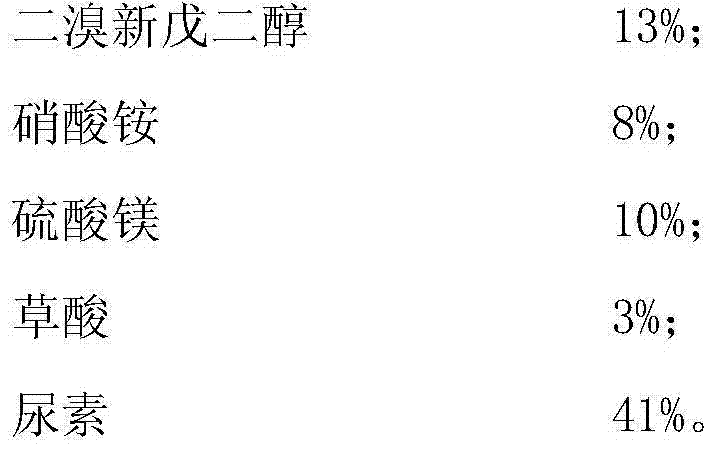

[0021] Components and their weight ratios: 25% decabromodiphenyl ether, 13% dibromoneopentyl glycol; 8% ammonium nitrate; 10% magnesium sulfate; 3% oxalic acid, 41% urea.

[0022] Preparation method: Mix the above components into a blender, add water until submerged, and stir at 45°C for 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com