A 3D printing method and system for refractory metal parts

A refractory metal and 3D printing technology, applied in the field of 3D printing, can solve problems such as difficult to realize 3D printing, and achieve the effect of simple structure and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

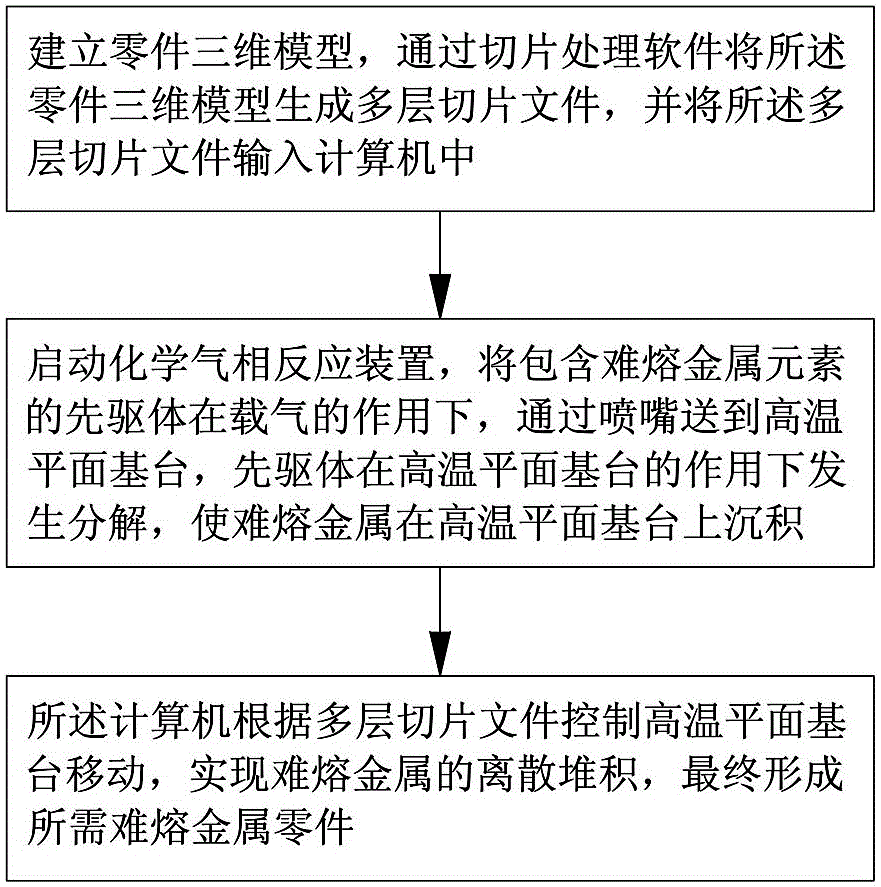

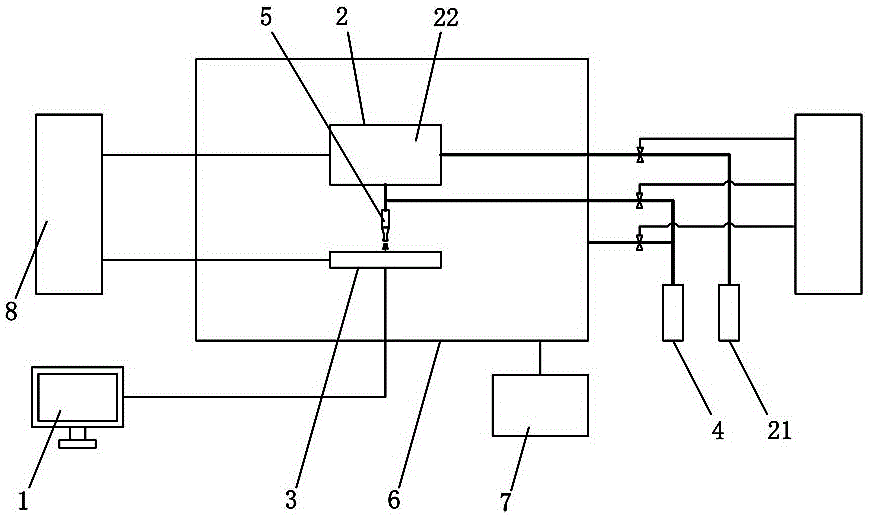

[0026] figure 1 A 3D printing method flow chart of a refractory metal part of the present invention is shown, the method includes the following steps:

[0027] S1: Establish a three-dimensional model of the part, generate a multi-layer slice file from the three-dimensional model of the part through slice processing software, and input the multi-layer slice file into the computer 1;

[0028] S2: Start the chemical gas phase reaction device 2, send the gaseous precursor containing refractory metal elements to the high-temperature flat base 3 through the nozzle 5 under the action of the carrier gas, and the gaseous precursor is generated under the action of the high-temperature flat base 3 Decompose, so that the refractory metal is deposited on the high-temperature flat base 3;

[0029] S3: The computer 1 controls the movement of the high-temperature planar abutment 3 according to the multi-layer slicing file, realizes the discrete accumulation of refractory metals, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com