Solar heat pump composite modular dryer for wolfberry

A technology of solar heat pump and composite module, which is applied in dryers, dryers, partial agitation dryers, etc., can solve the problems of large energy consumption, large channel heat loss, environmental pollution, etc., and achieve high operational safety and ensure food quality Safe and guarantee the effect of drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

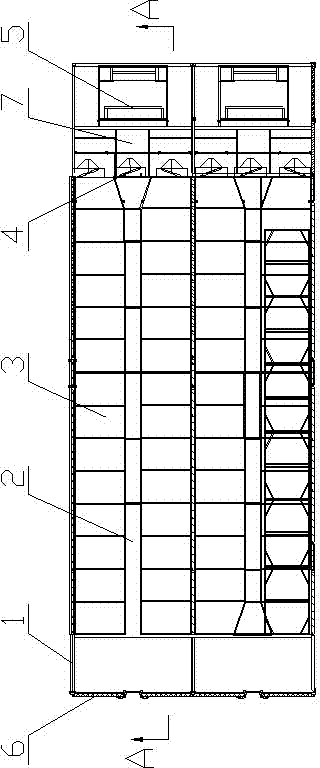

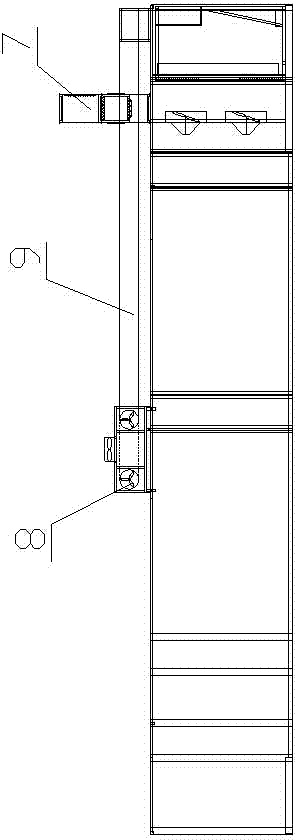

[0021] see figure 1 , figure 2 , the present invention is a compound modular drying machine for wolfberry solar energy heat pump, which includes a plurality of cabinet drying channel modules, each cabinet drying channel module includes a cabinet body 1, and the middle section of the cabinet body 1 is provided with a heat preservation channel 2 and a drying channel Road 3, the drying tunnel 3 is located on the left and right sides of the heat preservation passage 2, the rear end of the heat preservation passage 2 and the drying passage 3 are provided with a blower 4, the rear of the blower 4 is provided with an auxiliary heating system 5, and the drying passage 3 A material inlet and outlet 6 is provided in the front, and a solar heat collection module is provided above the plurality of box drying modules, and the solar heat collection module is connected with the plurality of box drying modules through a hot air passage 7, and the A plurality of interfaces of the hot air cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com