A double-sided forming grid stab-proof material and its manufacturing process

A double-sided molding, stab-proof technology, applied in protective equipment, synthetic resin layered products, offensive equipment, etc., can solve the problem of stab-proof performance discount, and achieve the effects of high production efficiency, improved mechanical strength and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

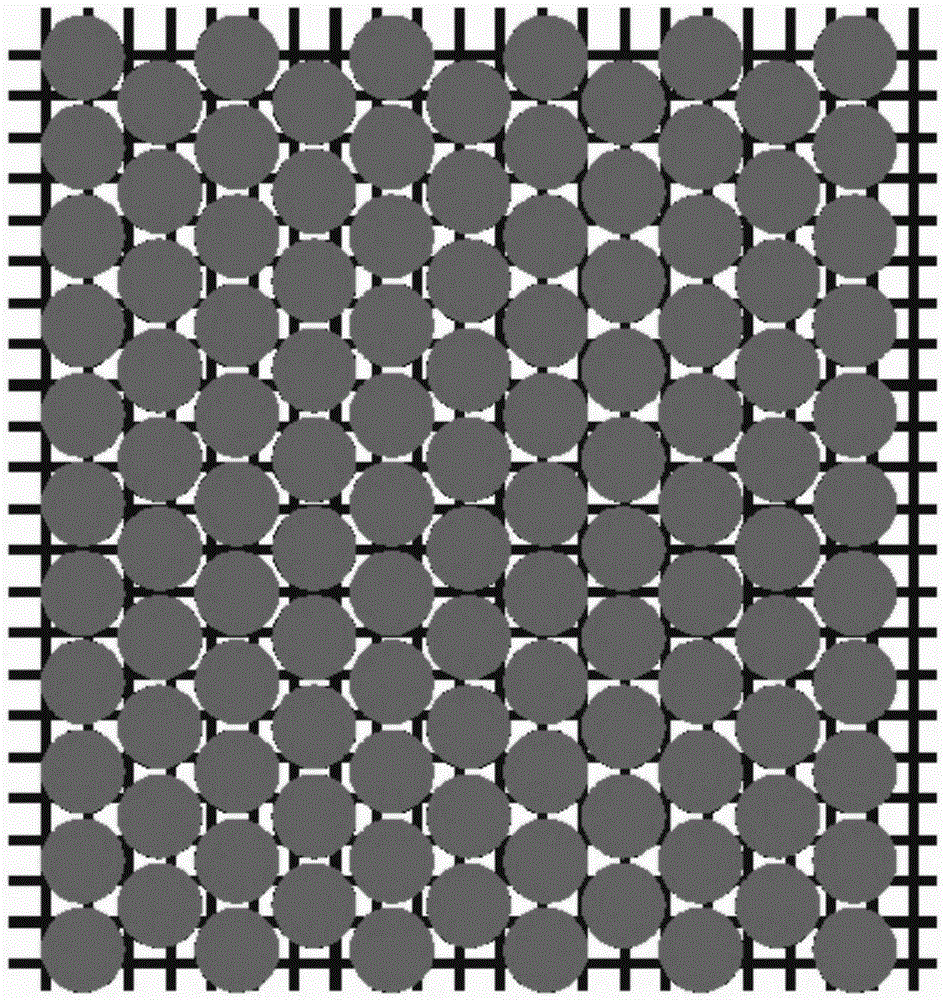

Embodiment 1

[0026] Using aramid 1414 mesh cloth, the surface density is 160g / m 2 , the thickness is 0.3mm, and the warp and weft density is 40×40 (root / 10cm). Polycarbonate resin is processed into round particles with a diameter of 10mm, a particle height of 1.5mm, and a particle gap of 0.8mm, and additives such as reinforcing agents, flame retardants, and color particles are added. Three layers of this double-sided forming grid composite material are used to be laminated alternately, and then the edges of each layer are sparsely stitched to each other, and then cut to make a protective body (stab-proof liner). The total weight of the anti-stab clothing of specification 175cm, 90A prepared with this protective body is 2.3kg, and the thickness is 10.2mm. The stab-resistant clothing adopts the latest standard GA68-2008 of the public safety industry of the People's Republic of China to conduct a puncture test according to 24J energy, and the results show that the stab-resistant clothing ful...

Embodiment 2

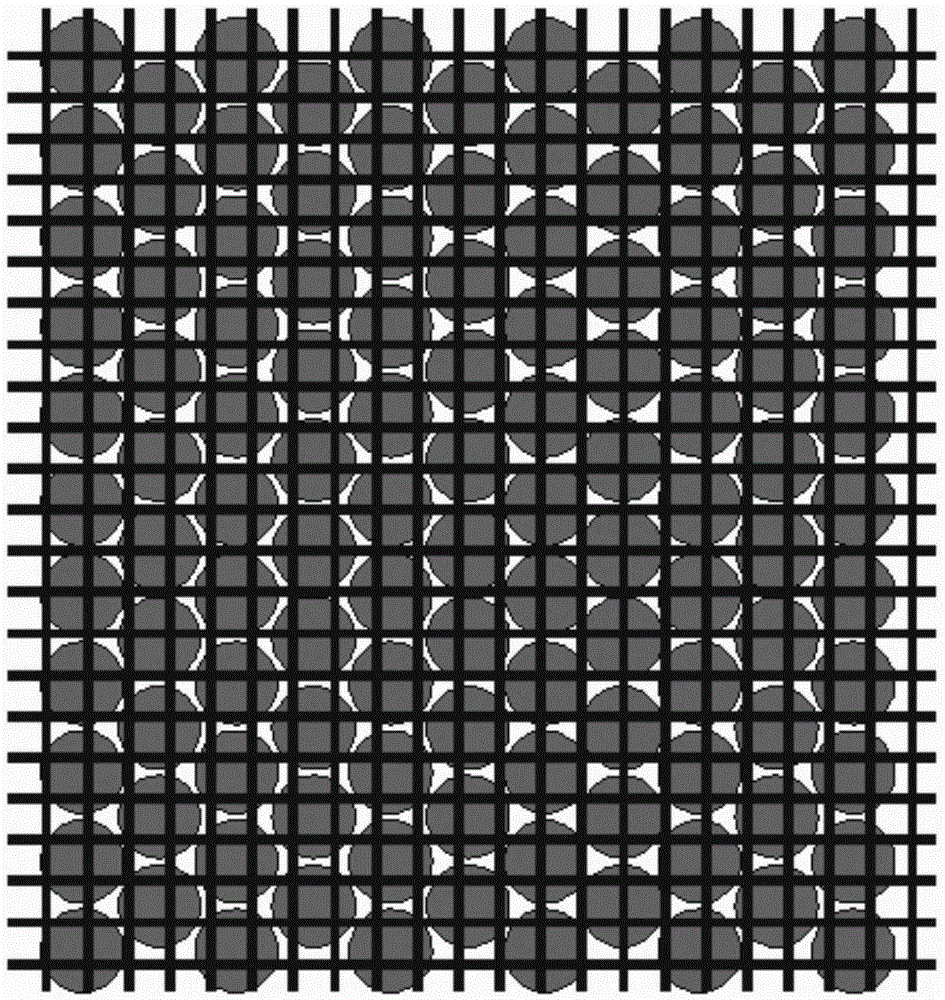

[0034] Aramid 1414 mesh cloth is used, the surface density is 180g / m2, the thickness is 0.4mm, and the warp and weft density is 36×36 (root / 10cm). The polyamide resin is processed into square particles with a side length of 5mm, a particle height of 1.3mm, and a particle gap of 0.8mm, and additives such as reinforcing agents, flame retardants, and color particles are added. Three layers of this double-sided forming grid composite material are used to be laminated alternately, and then the edges of each layer are sparsely stitched to each other, and then cut to make a protective body (stab-proof liner). The total weight of the anti-stab clothing of specification 175cm, 90A processed with this protective body is 2.4kg, and the thickness is 9.6mm. The stab-resistant clothing adopts the latest standard GA68-2008 of the public safety industry of the People's Republic of China to conduct a puncture test according to 24J energy, and the results show that the stab-resistant clothing f...

Embodiment 3

[0042]Glass fiber mesh cloth is used, the surface density is 160g / m2, the thickness is 0.4mm, and the warp and weft density is 34×34 (root / 10cm). Epoxy resin is processed into round particles with a diameter of 10mm, a particle height of 1.2mm, and a particle gap of 0.8mm. Add tougheners, diluents, and color particles to the epoxy resin. Four layers of this double-sided forming grid composite material are used to be laminated alternately, and then the edges of each layer are sparsely stitched to each other, and then cut to make a protective body (stab-proof liner). The total weight of the anti-stab clothing of specification 175cm, 90A prepared by this protective body is 2.8kg, and the thickness is 11.4mm. The stab-resistant clothing adopts the latest standard GA68-2008 of the public safety industry of the People's Republic of China to conduct a puncture test according to 24J energy, and the results show that the stab-resistant clothing fully meets the technical requirements st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com