Reflective broadband 1/4 wave plate

A reflective, wave plate technology, applied in the direction of optics, instruments, optical components, etc., can solve the problems that cannot meet the broadband application, and achieve the effect of broadband high-efficiency reverse diffraction and high-efficiency diffraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

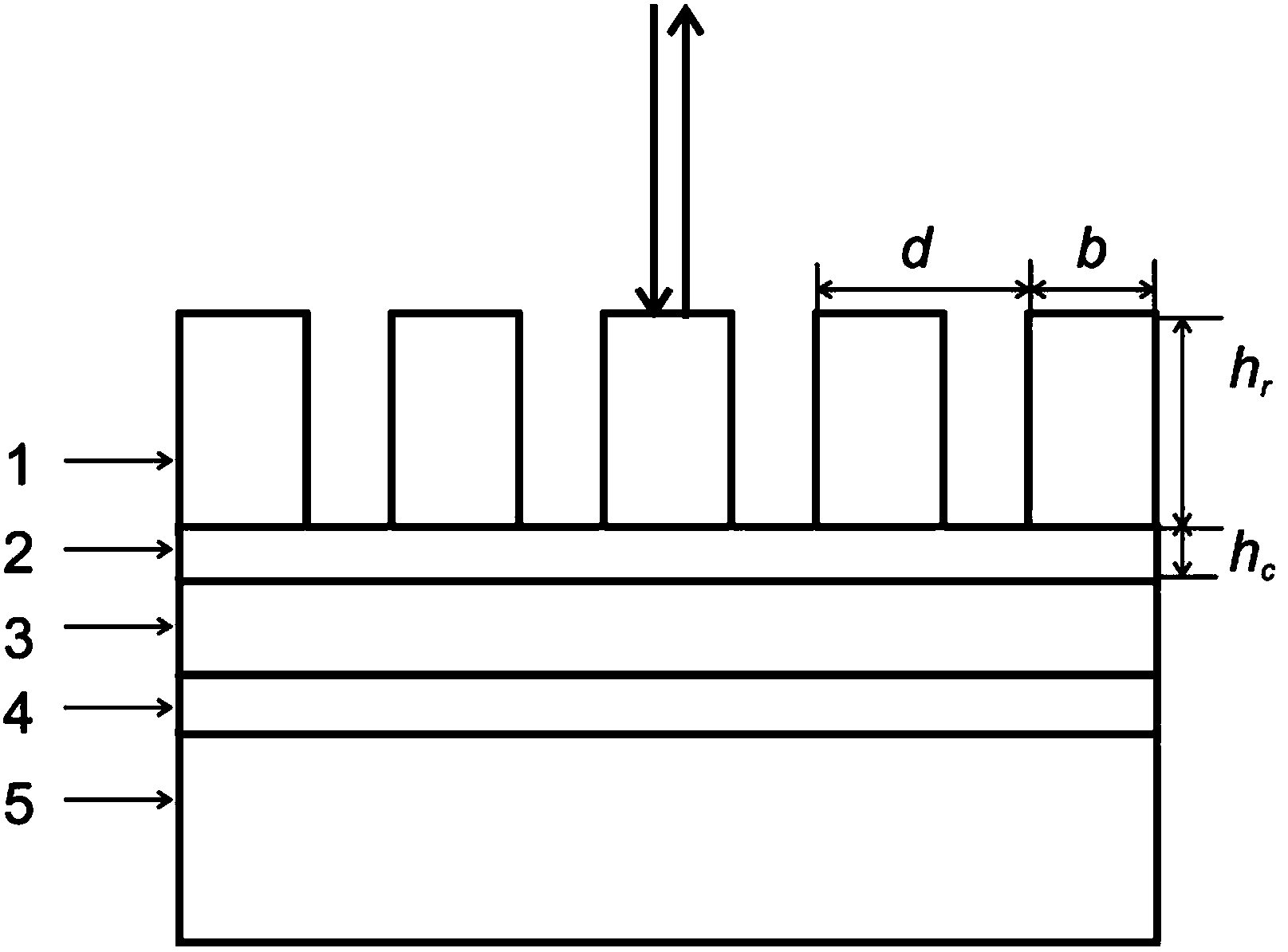

[0020] A broadband reflective wave plate for a central wavelength of 1550 nanometers, its structure is as follows figure 1 As shown, an aluminum oxide film 4, a silver film 3 larger than 100 nanometers, an aluminum oxide film 2 (connection layer) of 61 nanometers, and a silicon oxide film 1 are sequentially coated on the substrate 5, and the silicon oxide film layer 1 etches a rectangular groove grating . The grating period d is 1178-1188 nanometers, and the range of the grating ridge width b can be determined according to the grating period and duty cycle, which is between 300-303 nanometers. In this embodiment, the ridge width is 301.5 nanometers, and the etching depth h r 2517-2527 nm, duty cycle 0.255, connecting layer thickness h c is 61 nm.

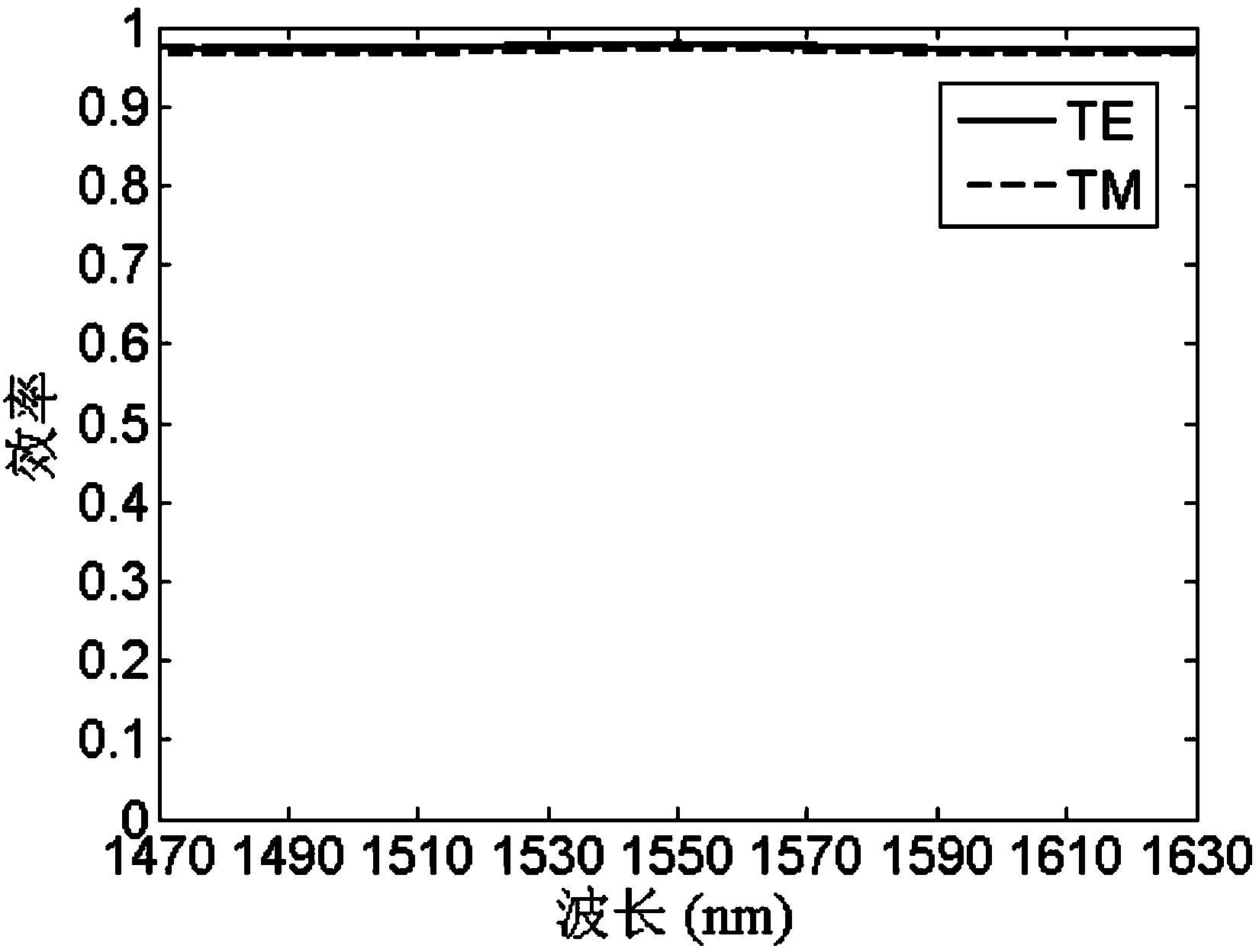

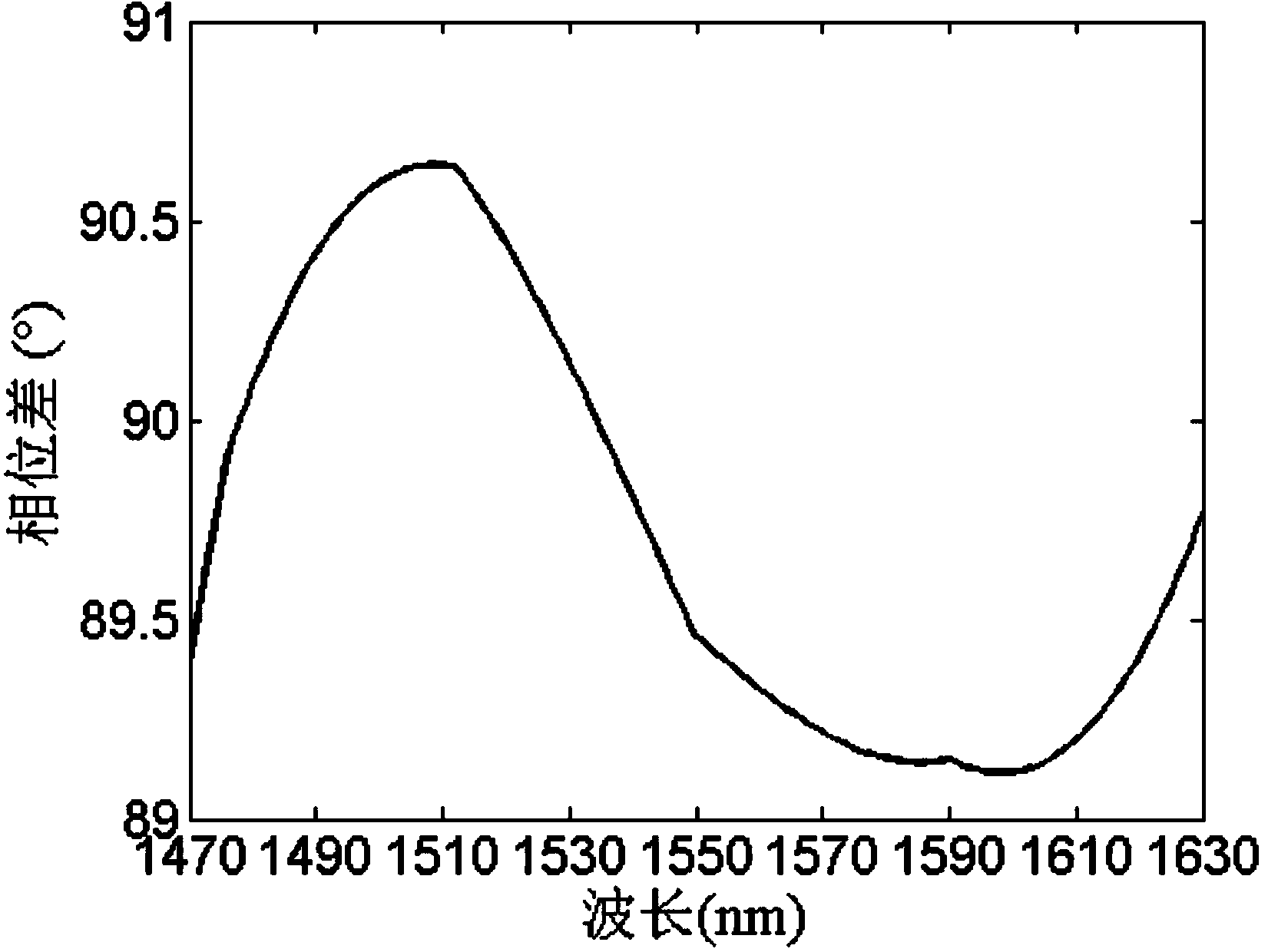

[0021] Table 1 provides a series of specific embodiments applicable to the present invention, wherein: d is the grating period, h r is the grating etching depth, λ is the incident wavelength, η TE is the 0th-order diffraction ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com