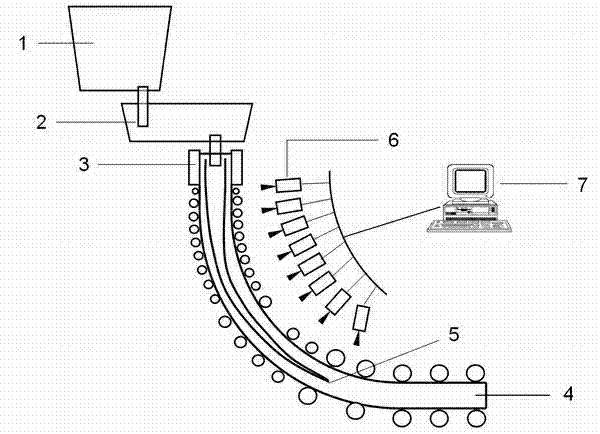

Method for optimizing convectional heat exchange confident of cooling water in continuous casting secondary cooling zone

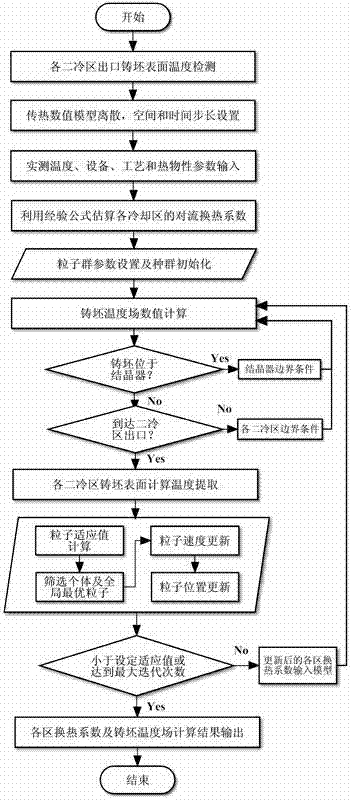

A convective heat transfer coefficient and optimization method technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of heat transfer lag, cumbersome process, and consumption, so as to reduce the influence of human factors and avoid cumbersome process, optimization and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

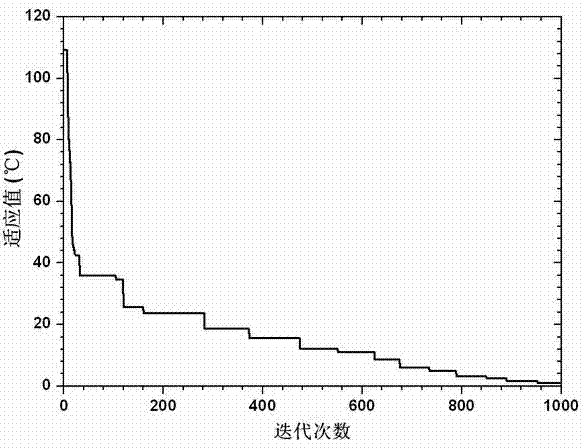

Examples

Embodiment

[0067] The arc-shaped slab continuous casting machine of a domestic steel plant has a caster radius of 10.75m, a metallurgical length of 28.83m, and a mold length of 900mm. The secondary cooling section of the casting machine is divided into 8 areas. The distance from the meniscus of each cooling area The distances and lengths are shown in Table 1.

[0068] Table 1 The distance and length of each cooling zone from the meniscus

[0069]

[0070] In production, the casting machine is used to cast a steel grade with a section of 2450mm×320mm, the liquid level is 800mm, the water volume of the wide and narrow sides of the mold is 5800L / min and 650L / min respectively, and the temperature difference between the water entering and leaving the mold is 4.9°C. The liquidus and solidus temperatures of the steel grades are 1514.4°C and 1453.3°C, respectively, and the casting superheat is 30°C. The chemical composition of the steel grades is shown in Table 2.

[0071] Table 2 Chemical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com