Terahertz/laser lamination detector

A detector, terahertz technology, applied to detectors in multispectral composite detection, multimode field, to achieve the effect of small size, good conductivity, and simplified overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

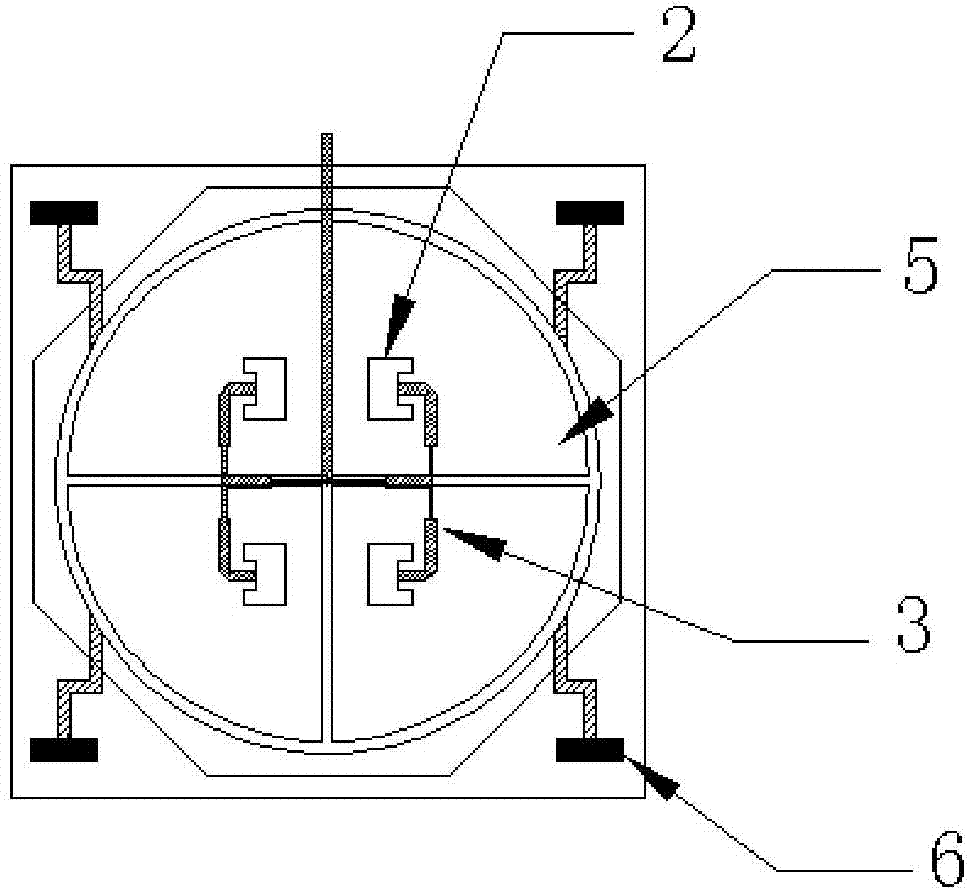

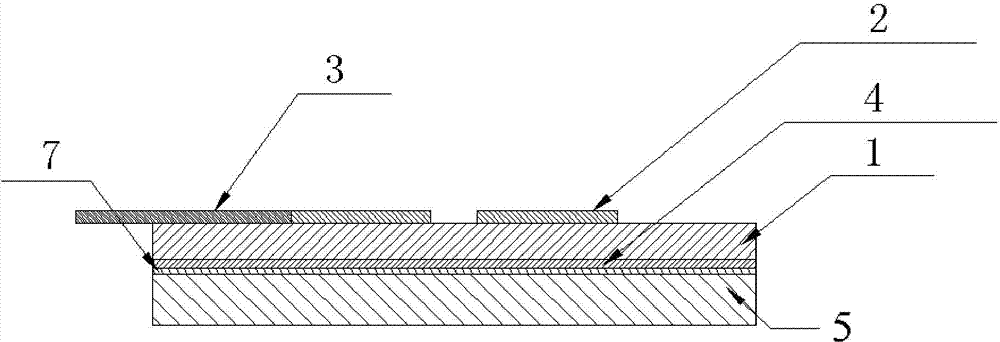

[0023] figure 1 , figure 2 Shown is a terahertz / laser stacked detector shown in Example 1. The dual-mode stacked detector is composed of a microstrip antenna and a four-quadrant laser detector, wherein the microstrip antenna is formed by an insulating dielectric substrate 1 The upper conductive film patch 2, the metal feeder 3, and the conductive film ground plate 4 under the insulating dielectric substrate 1 are formed. The conductive film ground plate 4 of the microstrip antenna is pasted on the four sides by an infrared-transmitting adhesive 7. On the surface of the quadrant laser detector 5 , the four-quadrant laser detector outputs signals through metal electrodes. The conductive film patch is a 2*2 array, symmetrically distributed according to the center of the detector. The conductive film patches in each array are connected to a metal feed line. The conductive film is a graphene film, and the graphene film is made of three layers of graphene film. The metal feeder...

Embodiment 2

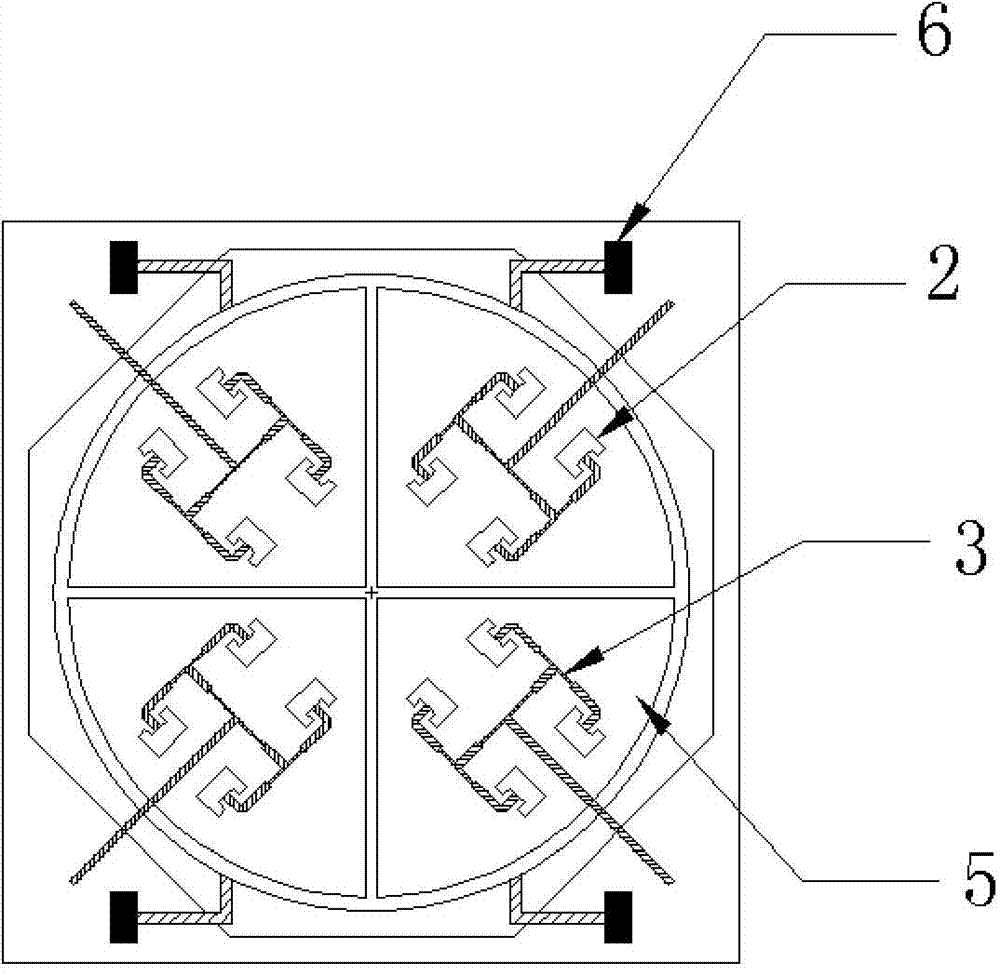

[0026] image 3 It is a terahertz / laser laminated detector shown in Embodiment 2. The conductive thin film patch is a 4*4 array, which is composed of four conductive thin film patches in a 2*2 array.

[0027] The patch size and arrangement of the microstrip antenna are related to the required THz frequency and the number of elements of the antenna, and are set according to specific conditions.

[0028] The concrete preparation process of embodiment 2 is as follows:

[0029] 1. The insulating dielectric substrate 1 is sapphire with a thickness of 0.2 mm, the graphene film patch 2 is a 4×4 patch array pattern, and the material of the metal feeder 3 is chromium / gold. According to the shape of the designed patch antenna, a photolithographic pattern is prepared, including a photolithographic plate for preparing a feeder pattern and a photolithographic pattern for preparing an antenna pattern.

[0030] 2. A single-layer graphene film is grown on a copper foil substrate with chemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com