A hydrogenation demetalization catalyst for heavy oil, and preparation and applications thereof

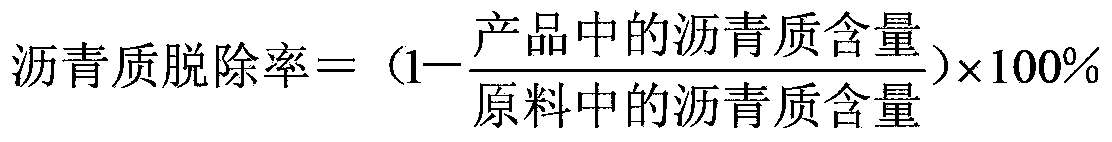

A catalyst and metal technology, applied in the field of hydrodemetallization catalyst and its preparation and application, can solve the problem of low removal rate of asphaltene, low removal rate of asphaltene, heavy metal removal rate and asphaltene removal rate. The division rate cannot achieve a good match, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

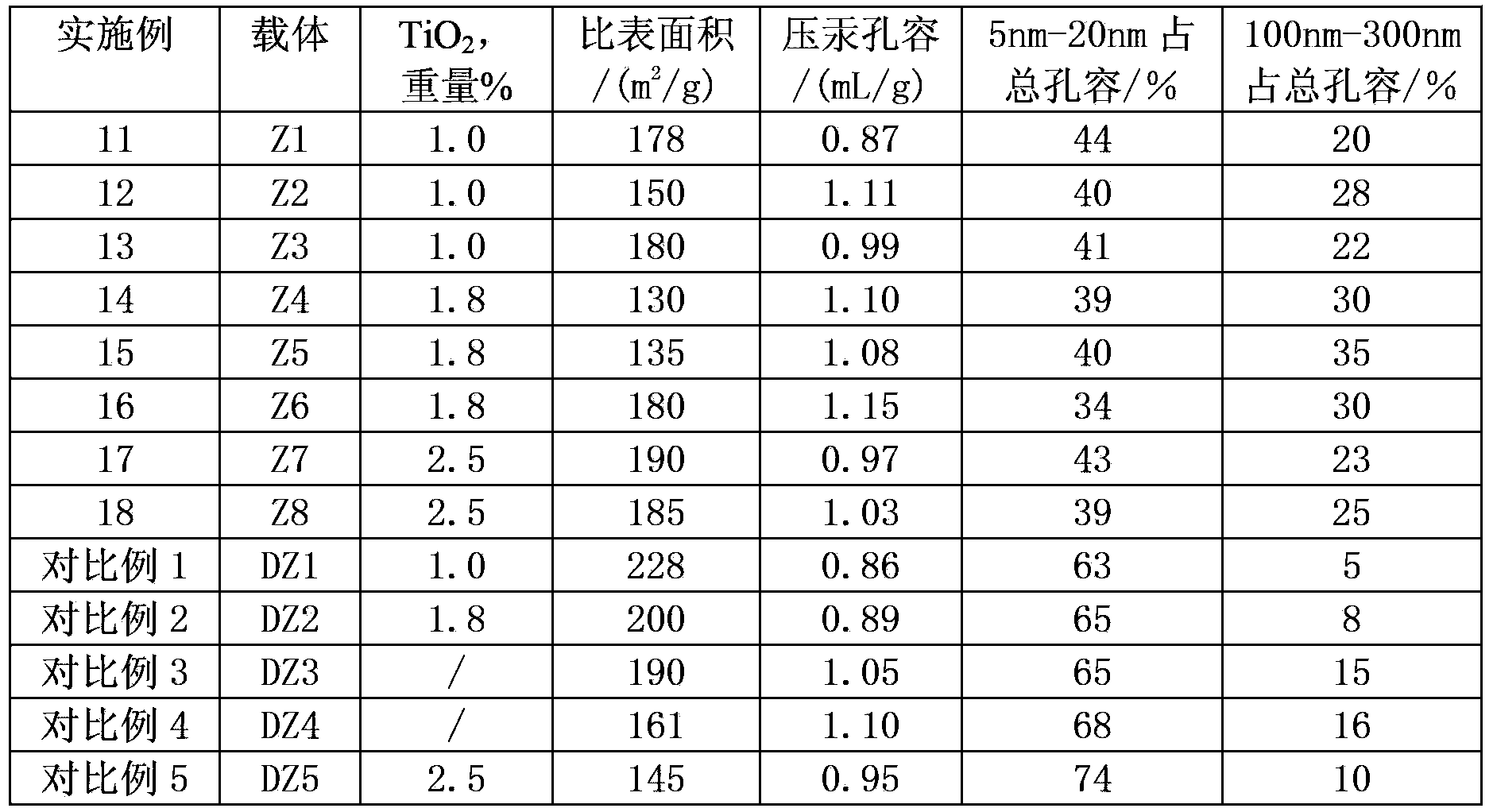

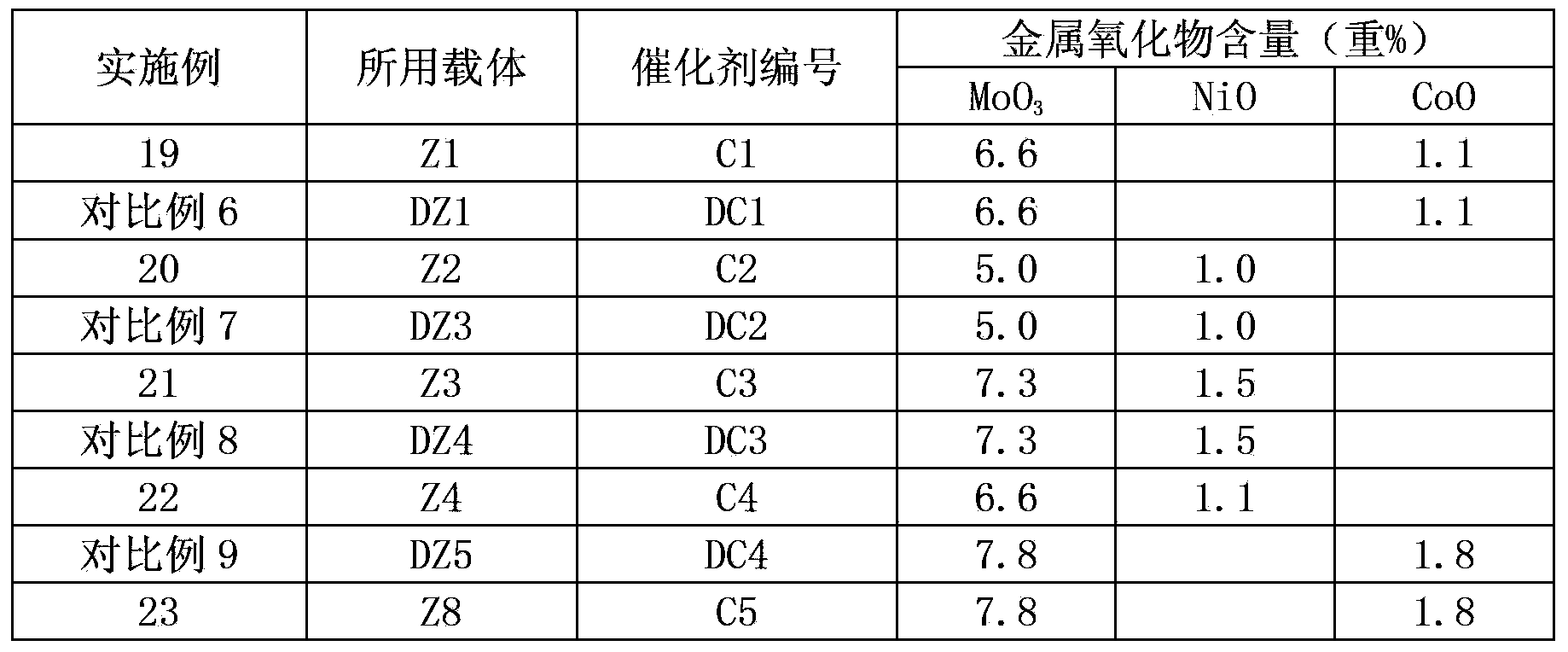

Examples

Embodiment 1

[0070] Weigh 1000 grams of PA-1, then add 1000 milliliters of an aqueous solution containing 10 milliliters of nitric acid (product of Tianjin Chemical Reagent No. Dry the wet strips at 120°C for 4 hours to obtain dry strips, shape the dry strips, sieve, grind and sieve the dry strip materials (generally called industrial dry strip waste) with a length of less than 2mm, and take 100-200 Mesh sieving to obtain the modified PC-A1 of PA-1. See Table 1 for the k value of PC-A1.

Embodiment 2

[0072] Weigh 1000 grams of PA-1, then add 1000 milliliters of an aqueous solution containing 10 milliliters of nitric acid (product of Tianjin Chemical Reagent No. The wet strips were dried at 120°C for 4 hours, and roasted at 800°C for 4 hours to obtain the carrier. The carrier strips were shaped and sieved, and the carrier strip materials (generally called industrial carrier waste) with a length of less than 2mm were ground, sieved, and collected. Among them, sieve with 100-200 meshes to obtain the modified product PC-A2 of PA-1. See Table 1 for the k value of PC-A2.

Embodiment 3

[0074] Weigh 1000g of PA-2, and flash dry at 400°C for 6 minutes to obtain PC-A3, a modified product of PA-2. See Table 1 for the k value of PC-A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com