A preparing method of biological fertilizer bacterium granules

A manufacturing method and biological technology, applied in the direction of fertilizer form, fertilizer mixture, fertilization device, etc., can solve the problems of short shelf life, prone to qualitative change, dusty, etc., so as not to be affected by moisture and pollution, extend the shelf life, Not prone to dusty effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

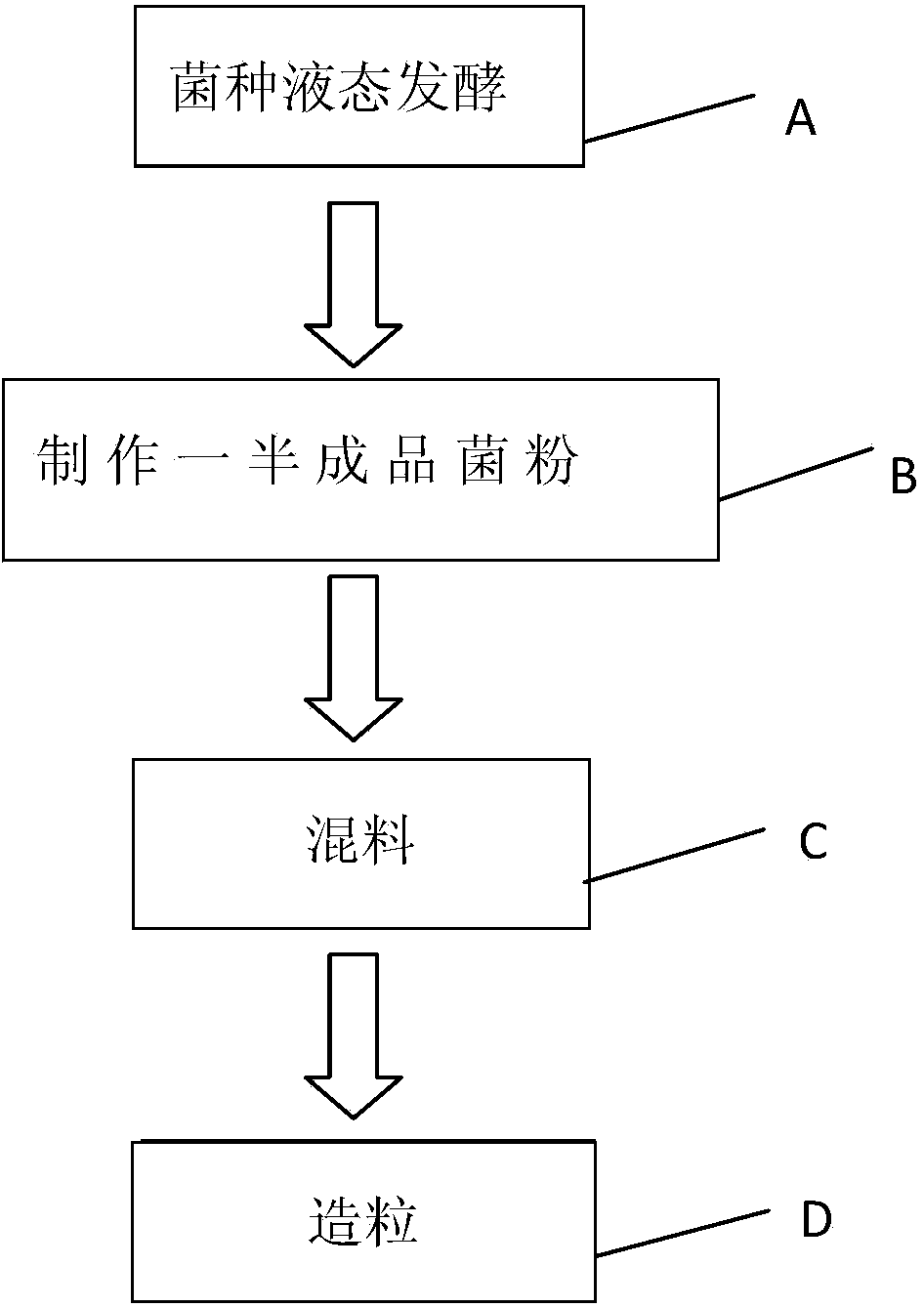

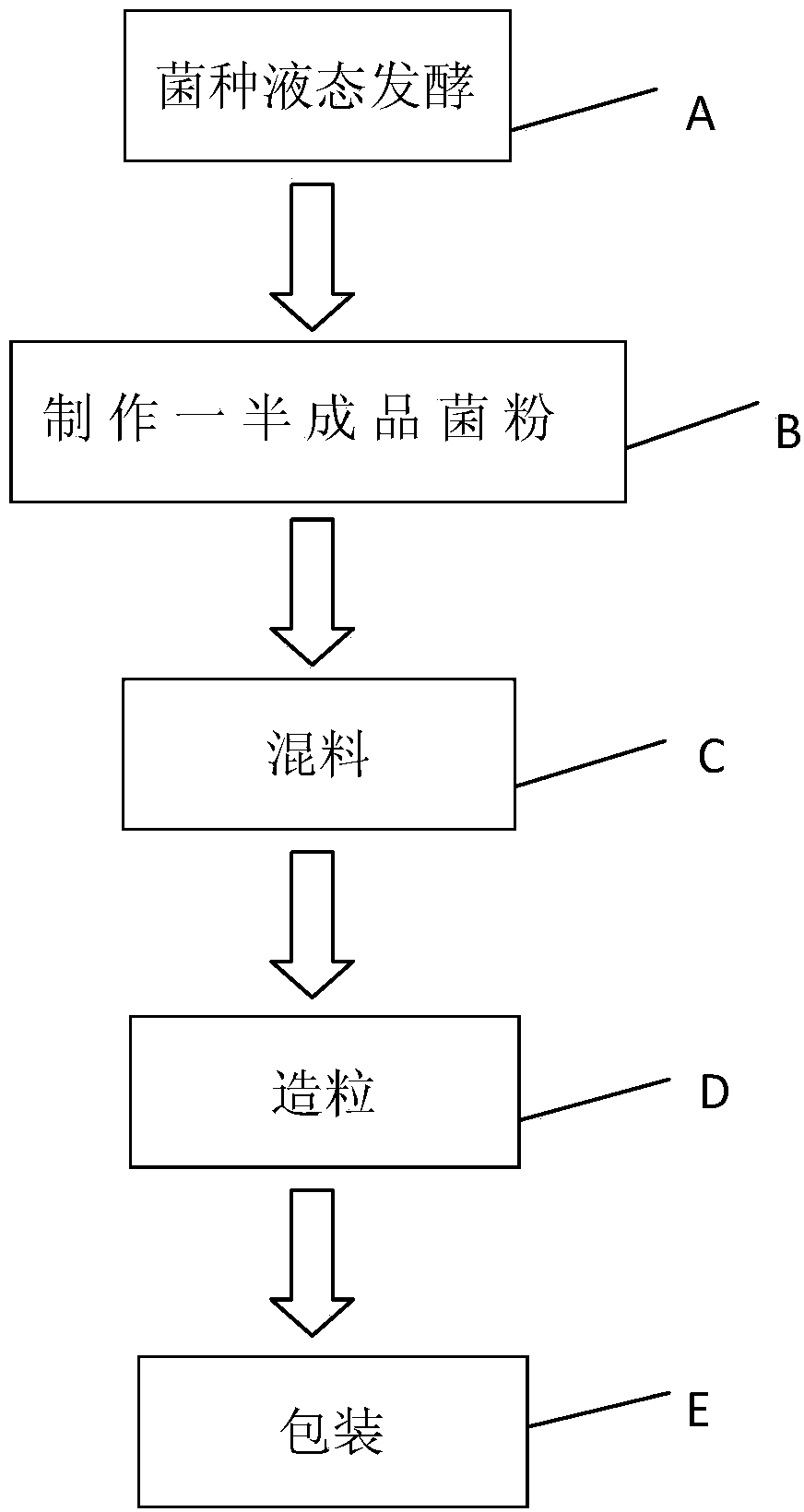

[0019] see figure 1 As shown, it is a step of an embodiment of the present invention. The manufacturing method of a kind of biological fertilizer granule preparation of the present embodiment, it comprises the following steps.

[0020] Step A is the liquid state fermentation of strains, which inoculates a microorganism to carry out fermentation to mass-produce microbial spores. Phosphorus or algae. In step A, a fermentation vessel can be used to contain a liquid medium, which is inoculated with the microorganism after being sterilized, wherein the fermentation vessel can be a Erlenmeyer flask, a serum bottle, a fermenter or other vessels that can be used for liquid fermentation. The sterilization procedure of step A is to put the liquid culture medium into the fermentation vessel, and then sterilize it by high temperature and high pressure sterilization method or boiler steam sterilization method.

[0021] Step B is to make half of the finished bacterial powder. First, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com