Organic semiconductor material, preparation method and electroluminescent device

A technology of electroluminescent devices and organic semiconductors, applied in the fields of organic semiconductor materials, preparation, and electroluminescent devices, can solve problems such as shortages, achieve high thermal stability, improve luminous efficiency, and the effect of simple and easy synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of organic semiconductor material, comprises the steps:

[0027] Provides compound A: and compound B: Under an inert atmosphere, first dissolve compound A in an organic solvent, then add compound B, an inorganic base and a catalyst to the organic solvent containing compound A and react at 70-120°C for 6-15 hours, the compound A The molar ratio to compound B is 1:2 to 1:2.4, and the chemical formula of the organic semiconductor material obtained by stopping the reaction is as follows:

[0028]

[0029] The preparation method of the organic semiconductor material further includes a post-processing step. The post-processing step specifically includes: using n-hexane as eluent to separate and purify the organic semiconductor material obtained by stopping the reaction through a silica gel layer, and vacuum drying to obtain the target product.

[0030] The condition of the vacuum drying is drying at 50-70° C. for 12-2...

Embodiment 1

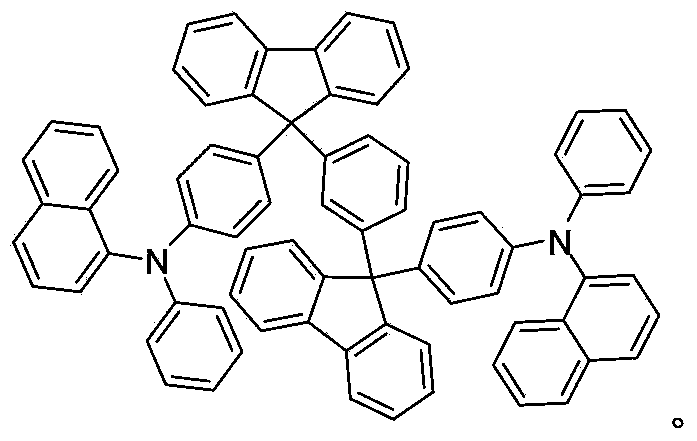

[0041] N,N'-(4,4'-(9,9'-(1,3-phenylene)bis(9H-fluorene-9,9-diyl))bis(4,1-phenylene))bis (N-phenylnaphthyl-1-amine) preparation process preparation steps are as follows:

[0042]

[0043] Under nitrogen protection, 1,3-bis(9-(4-tetrabromophenyl)-9H-fluoren-9-yl)benzene (57.3g, 80mmol) was dissolved in 200mL N,N-dimethylformamide (DMF) solution, then added N-phenylnaphthalene-1-amine (35.0g, 160mmol), potassium carbonate (22.1g, 160mmol) and cuprous iodide (1.52g, 8mmol). The reactants were stirred and reacted at 120° C. for 6 hours. Stop the reaction and cool to room temperature, filter, and wash the solid three times with distilled water to obtain the product N,N'-(4,4'-(9,9'-(1,3-phenylene)bis(9H-fluorene-9,9 -diyl))bis(4,1-phenylene))bis(N-phenylnaphthyl-1-amine), and then use the eluent n-hexane to separate by silica gel column chromatography, and then dry at 50°C under vacuum for 24h An off-white solid was obtained. The yield was 83%.

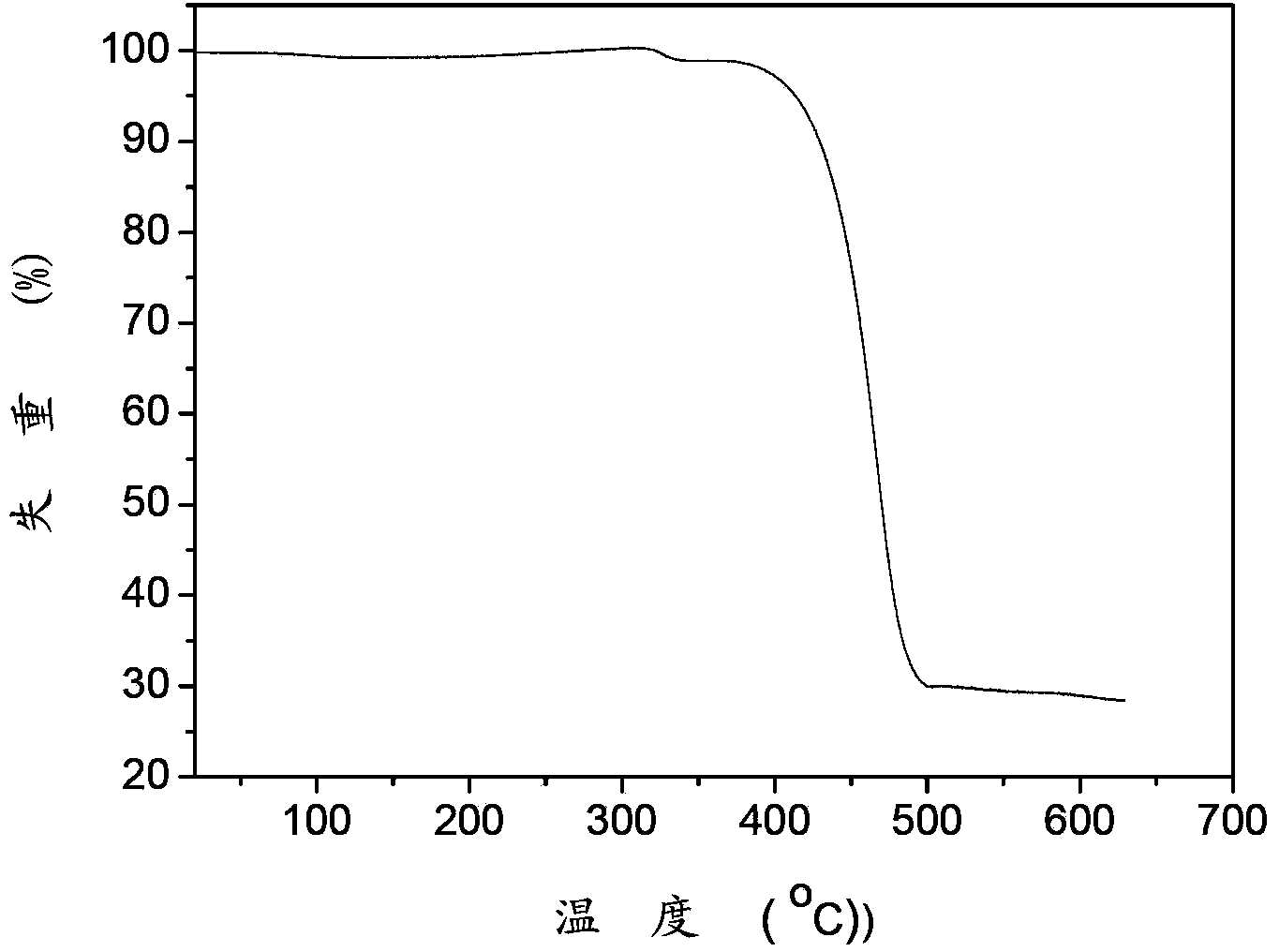

[0044] Experimental test dat...

Embodiment 2

[0048] N,N'-(4,4'-(9,9'-(1,3-phenylene)bis(9H-fluorene-9,9-diyl))bis(4,1-phenylene))bis (N-phenylnaphthyl-1-amine) preparation process preparation steps are as follows:

[0049]

[0050] Under nitrogen protection, 1,3-bis(9-(4-tetrabromophenyl)-9H-fluoren-9-yl)benzene (57.3g, 80mmol) was dissolved in 200mL toluene (Tol) solution, and then added N-Phenylnaphthalen-1-amine (38.5g, 176mmol), cesium carbonate (57.2g, 176mmol), copper powder (0.768g, 12mmol). The reactants were stirred and reacted at 110° C. for 9 hours. Stop the reaction and cool to room temperature, filter, and wash the solid three times with distilled water to obtain the product N,N'-(4,4'-(9,9'-(1,3-phenylene)bis(9H-fluorene-9,9 -diyl))bis(4,1-phenylene))bis(N-phenylnaphthyl-1-amine), and then use the eluent n-hexane to separate by silica gel column chromatography, and then dry at 50°C under vacuum for 24h An off-white solid was obtained. The yield was 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com