Side flow denitrification tank and side flow denitrification method

A technology of denitrification and secondary settling tank, which is applied in chemical instruments and methods, anaerobic digestion treatment, water/sludge/sewage treatment, etc., can solve the problems affecting the denitrification effect of the system, increase power consumption, etc., and achieve improved denitrification Effect of Phosphorus, Reduced Dilution, Enhanced Treatment Capacity and Treatment Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

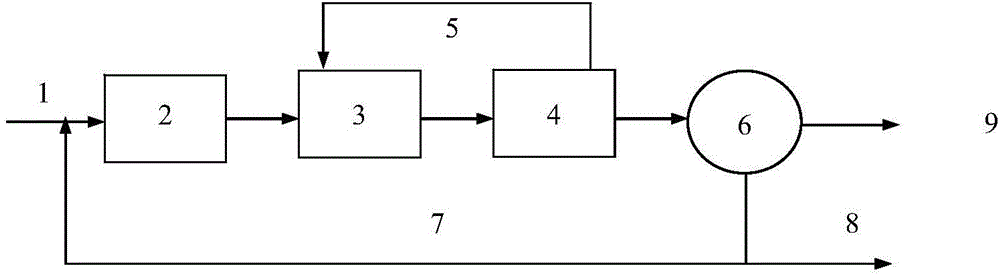

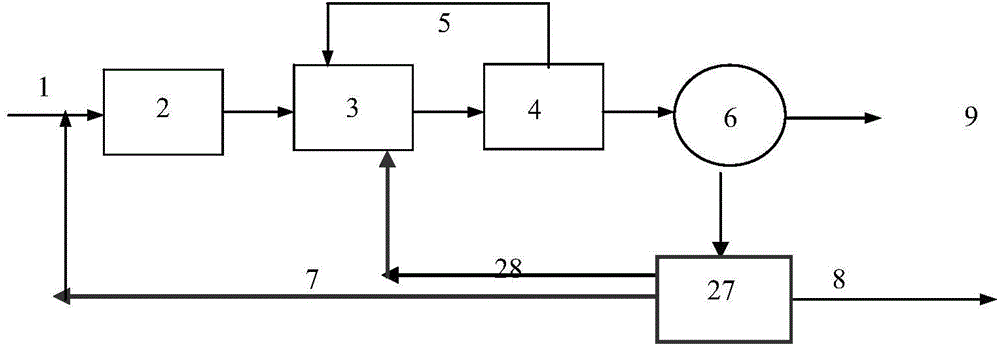

[0037] Example 1: Combination of side stream denitrification tank and AAO process

[0038] The equipment combining side stream denitrification tank with AAO process, see figure 2 and Figure 5, including the reaction tank grid used as anaerobic zone 2, anoxic zone 3, aerobic zone 4 and secondary sedimentation tank 6, anaerobic zone 2, anoxic zone 3, aerobic zone 4 and secondary sedimentation tank 6 pass through the pipeline in sequence Connection, the aerobic zone 4 and the anoxic zone 3 are connected through the mixed liquid return pipe 5 .

[0039] The bottom of the secondary settling tank 6 is connected to the middle of the bottom of the side flow denitrification tank 27 through the mud inlet pipe 10, and the side of the side flow denitrification tank near the inlet of the mud inlet pipe is provided with a slant plate 12, and the slant plate 12 is supported by a slant plate edge bracket 15 , the edge support 15 of the inclined plate is fixed on the inner wall of the pool...

Embodiment 2

[0043] Example 2: Combination of side stream denitrification sewage treatment method and AAO process

[0044] Inlet flow is 40000m 3 / day, the influent water quality is:

[0045] BOD5≤160mg / L; CODcr≤300mg / L; SS≤180mg / L; TN≤45mg / L; NH 3 -N≤35mg / L; TP≤4mg / L.

[0046] Using the side flow denitrification tank of embodiment 1, the sewage to be treated is treated according to the AAO biochemical reaction process, first enters the anaerobic zone 2, and then enters the anoxic zone, the aerobic zone and the secondary sedimentation tank for treatment, and the secondary sedimentation tank is discharged The mud side flow enters the sludge denitrification tank, and the residence time is 1 hour. The nitrate concentration entering the side flow denitrification tank is 15 mg / L, and the sludge concentration entering is 8000 mg / L (water content 99.2%). The sludge concentration out of the mud denitrification tank is 18000mg / L, and the nitrate concentration is 3mg / L. The sludge after endogeno...

Embodiment 3

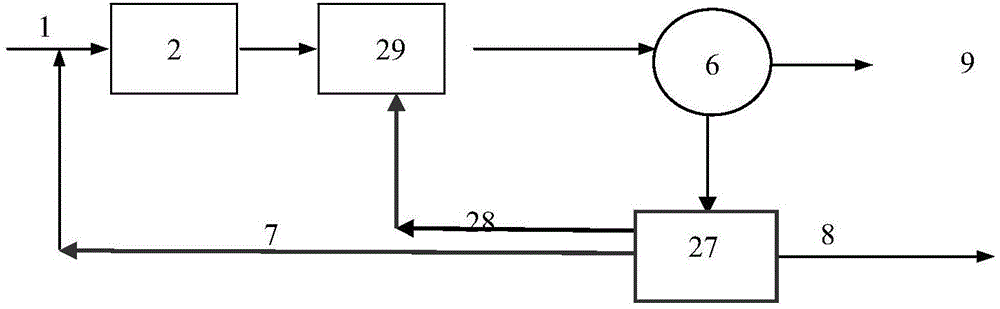

[0051] The effluent has reached the first-level A standard of the national "Urban Sewage Treatment Plant Pollutant Discharge Standard". Example 3: Combination of Side Stream Denitrification Sewage Treatment Method and Oxidation Ditch Process

[0052] Inlet flow is 30000m 3 / day, the influent water quality is:

[0053] BOD5≤180mg / L; CODcr≤330mg / L; SS≤190mg / L; TN≤40mg / L; NH 3 -N≤30mg / L; TP≤3mg / L.

[0054] see image 3 , using the side flow denitrification tank of embodiment 1, the sewage to be treated first enters the anaerobic zone 2, then enters the oxidation ditch 29 and the secondary sedimentation tank for processing, and the side flow of the sludge from the secondary sedimentation tank enters the sludge denitrification tank, The residence time is 1.5 hours, the nitrate concentration entering the side stream denitrification tank is 15mg / L, the sludge concentration entering is 8500mg / L, the sludge concentration flowing out from the sludge denitrification tank is 17000mg / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com