Holothurian antioxidative peptide

An antioxidant polypeptide and sea cucumber polypeptide technology, applied in the biological field, can solve the problems of low utilization rate of resources, waste of leftovers, environmental pollution, etc., and achieve the effects of improving the low utilization rate, eliminating side effects, and alleviating concerns about food safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of sea cucumber antioxidant polypeptide, the specific steps are as follows:

[0028] (1) Extraction of sea cucumber protein

[0029] Sea cucumber protein extraction process conditions are:

[0030] Wash sea cucumber or sea cucumber viscera 3-5 times, extraction pH is 7.0, extraction temperature is 40-80 ℃, solid-liquid ratio is 1:4-1:8 (weight ratio), extraction time is 2-6 h, centrifuged 10000g for 20 minutes, collect the supernatant, filter, concentrate and freeze-dry to obtain sea cucumber protein.

[0031] (2) Enzymatic hydrolysis of sea cucumber protein

[0032] Enzymes were purchased from Shanghai Bioreagent Company (Shanghai, China).

[0033] Use acid protease to hydrolyze sea cucumber protein, the protein concentration is 30mg / ml, the enzymolysis conditions are pH 3.5, temperature 50°C, enzymolysis time 6h, enzyme to substrate ratio (3000U / g), adjust pH with 2M HCl Stable, after hydrolysis for 6 hours, inactivate the enzyme in a boilin...

Embodiment 1

[0057] Weigh 5.0 grams of sea cucumber protein and dissolve it in deionized water to 250 ml, then adjust its pH to 3.0 with 2 mol / L HCl. First heat the solution to 50°C in a water bath, then add a corresponding amount of enzyme according to the enzyme-substrate ratio of 3000U / g, and the enzymatic hydrolysis time is 6 hours. Then inactivate the enzyme in a boiling water bath for 15 minutes, then centrifuge at 4000 rpm for 15 minutes after cooling. Collect the supernatant for later use.

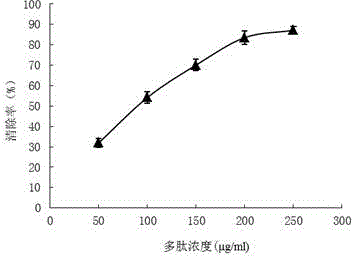

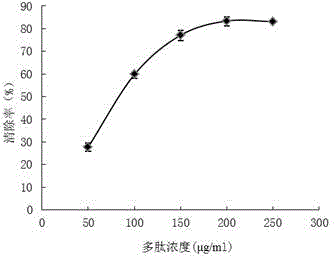

[0058] Use a membrane filtration system to separate the supernatant from the sea cucumber polypeptide solution by ultrafiltration, and use ultrafiltration membranes with different molecular weight cut-off ranges to separate the enzymatic hydrolysis products to obtain different components of ≥3000 Da, 1500-3000 Da, and ≤1500 Da to measure its antioxidant activity. The result of determination is: the component with molecular weight less than 1500Da has the best antioxidant activity.

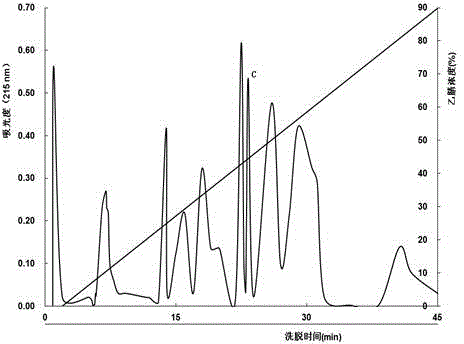

[0059] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com