Method for synthesizing N-phenylmaleimide/maleic anhydride binary copolymer

A technology of maleic anhydride binary copolymer and maleimide, which is applied in the field of polymer heat-resistant modifiers, can solve problems such as unstable quality, and achieve the effects of easy post-processing, small investment, and large returns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

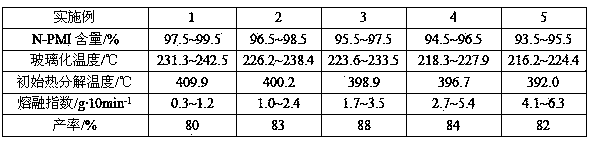

Embodiment 1

[0018] Add 174g of N-PMI, 49g of MAH and 250ml of xylene solvent into a 1000ml reaction kettle, pass in nitrogen gas, discharge the air in the kettle, raise the temperature to about 65°C, stir for 50-70min to form a homogeneous solution, quickly raise the temperature to about 95°C, add 0.5g dicumyl peroxide, raise the temperature to about 130°C, keep the pressure constant, and react for 3h. After the end, the temperature was raised until the residual solvent and the monomer evaporated, and then filtered and dried to obtain a pale yellow granular product.

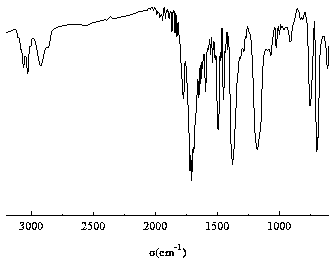

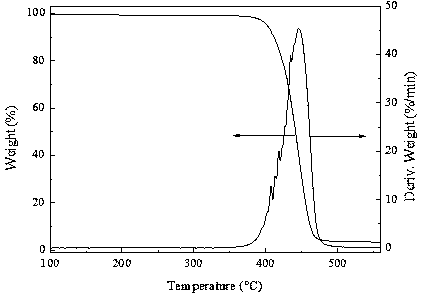

[0019] Depend on figure 1 The infrared spectrum of the N-PMI / MAH binary copolymer can be seen at 3030cm -1 The place is the stretching vibration absorption peak of C-H on the benzene ring in the N-phenylmaleimide unit, at 1449cm -1 、1496 cm -1 and 1599 cm -1 The spectrum peak at is the vibration absorption peak of the benzene ring skeleton C-C in the N-phenylmaleimide unit, at 754cm -1 and 698cm -1 is the out-of-plane ...

Embodiment 2

[0022] Add 130g of N-PMI, 49g of MAH and 250ml of xylene solvent into a 1000ml reaction kettle, pass in nitrogen gas, discharge the air in the kettle, raise the temperature to about 65°C, stir for 50-70min to form a homogeneous solution, quickly raise the temperature to about 95°C, add 0.5g dicumyl peroxide, raise the temperature to about 130°C, keep the pressure constant, and react for 3h. After the end, the temperature was raised until the residual solvent and the monomer evaporated, and then filtered and dried to obtain a pale yellow granular product.

Embodiment 3

[0024] Add 72g of N-PMI, 49g of MAH and 250ml of xylene solvent into a 1000ml reaction kettle, blow in nitrogen, discharge the air in the kettle, raise the temperature to about 65°C, stir for 50-70min to form a homogeneous solution, quickly raise the temperature to about 95°C, add 0.5g dicumyl peroxide, raise the temperature to about 130°C, keep the pressure constant, and react for 3h. After the end, the temperature was raised until the residual solvent and the monomer evaporated, and then filtered and dried to obtain a pale yellow granular product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com