Production technology of bile salt hydrolase-yielding lactobacillus paracasei dry powder living bacterium preparation

A technology of bile salt hydrolyzing enzyme and live bacteria preparation, which is applied in the direction of bacteria, microorganisms, preserved microorganisms, etc., and can solve the problems that have not been reported in relevant literature and patent reports at home and abroad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, the small-scale production technology of bile salt hydrolysis enzyme Lactobacillus paracasei KL1-Liu live bacterial preparation

[0036] 1. Activation and expansion of strains

[0037] The Lactobacillus paracasei KL1-Liu strain kept in the MRS test tube was cultured at 37°C for 16 hours with the improved MRS culture, activated for 2 to 3 generations, and refrigerated for later use; the activated bacterial solution was transplanted to 501 Rapeseed peptone-modified MRS medium was cultured at 37°C for 16 hours to obtain an expanded culture medium.

[0038] 2. Determination of fermentation medium

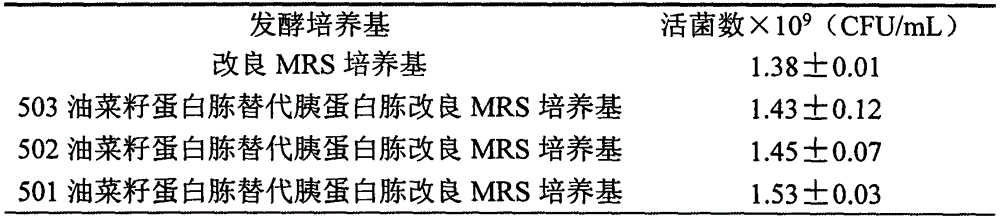

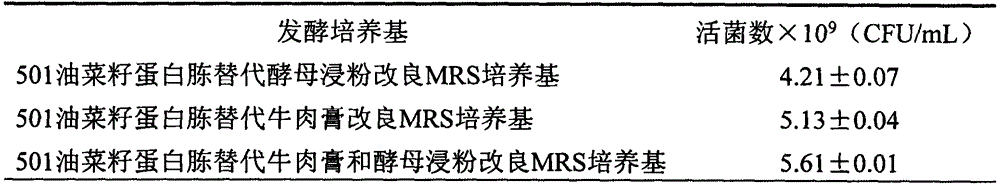

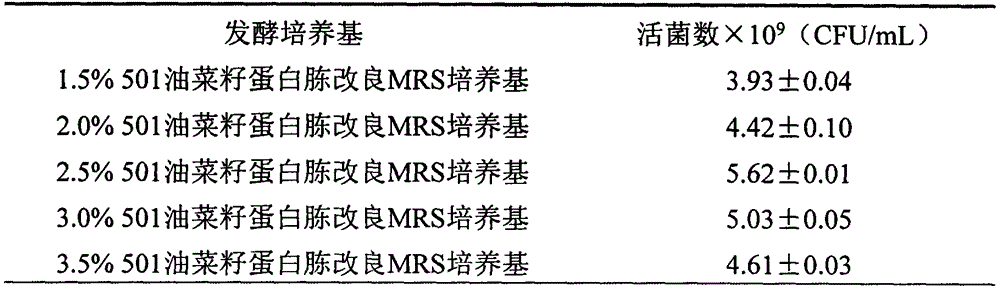

[0039] (1) Rapeseed peptone of different quality instead of partial nitrogen source test of improved MRS

[0040] Use 501 rapeseed peptone, 502 rapeseed peptone and 503 rapeseed peptone to replace the tryptone in the improved MRS medium, transplant the activated strains into the above medium at 4% inoculum, and inoculate at 34°C After 16 hours of fermentation, th...

Embodiment 2

[0068] Embodiment 2, the pilot-scale production technology of bile salt hydrolysis enzyme Lactobacillus paracasei KL1-Liu live bacterial preparation

[0069] 1. Pilot fermentation verification test

[0070] According to the optimization results of the orthogonal test, the pilot fermentation verification test was carried out. In a 50L automatic fermentation tank, 25L501 rapeseed peptone modified MRS was used as the fermentation medium, and 20% sterilized Na 2 CO 3 The solution controls the pH value of the fermentation broth, and the stirring speed is controlled at 140r / min. The improved MRS medium was used as the fermentation medium, and the pH of the fermented liquid was not controlled (natural) as the control group. MRS medium was used to detect the number of viable bacteria in the fermentation broth by the pour plate culture method, and each dilution was repeated three times. The results are shown in Table 6.

[0071] Table 6 Pilot fermentation verification test results

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com