Bile salt hydrolase and preparation method and special preparing strain thereof

A bile salt hydrolysis enzyme and product technology, applied in the direction of hydrolysis enzymes, microorganism-based methods, biochemical equipment and methods, etc., to achieve the effects of no toxic side effects, simple operation, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, Lactobacillus casei (Lactobacillus casei) KTx isolation and identification

[0030] 1. Screening of strains

[0031] 5ml of kefir filtrate was added to 45ml of physiological saline (with glass beads) to make bacterial suspension, and then 10-fold gradient dilution was made to 10 6 ~10 8 times, take 1ml and pour it into a plate (containing CaCO 3 MRS agar plate) at 37°C for 24h, pick the colonies with the dissolution circle and place them in the MRS liquid tube at 37°C for 12h enrichment culture, Grans staining, depending on the purity, draw the enrichment solution to 2% (volume ratio) The inoculation amount was inoculated in No. 1 medium with cholesterol as the sole carbon source (the medium containing 11 L of salt solution and 1.0 g of cholesterol; salt solution 1 (g / L): KH 2 PO 4 0.25; MgSO 4 ·7H 2 O 0.25; FeSO 4 5mg; NaCl 5mg; during preparation, dissolve cholesterol in saline solution I and then shake and emulsify with an ultrasonic cell pulver...

Embodiment 2

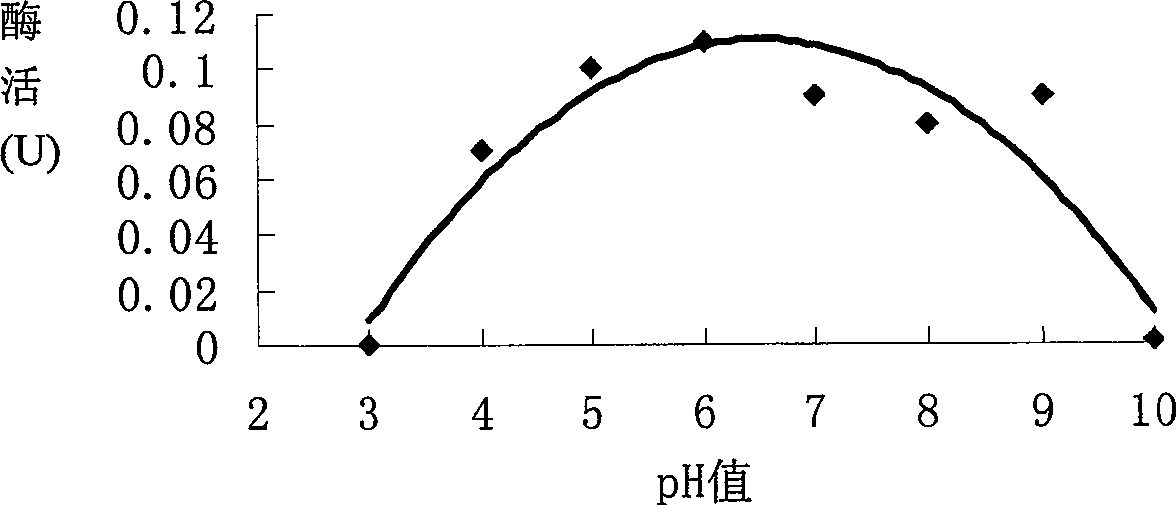

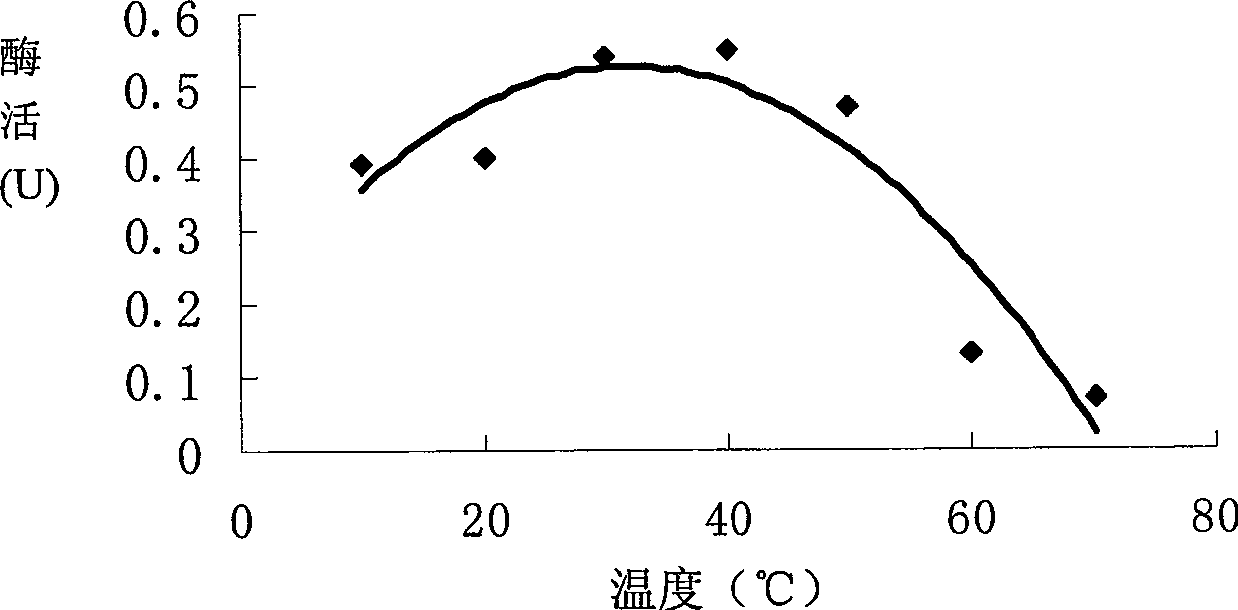

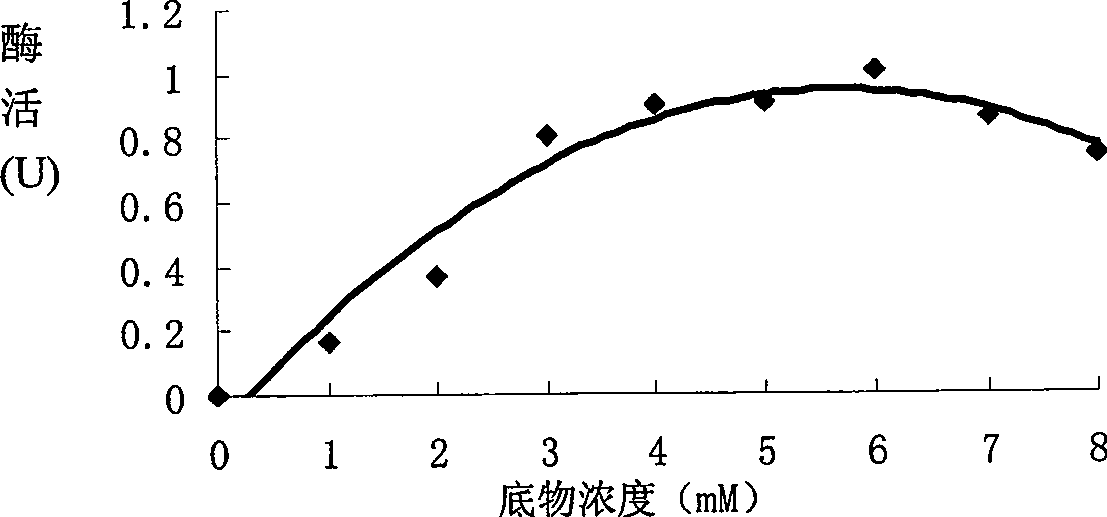

[0040] Embodiment 2. Optimization of fermentation conditions of Lactobacillus casei KTx and detection of bile salt hydrolase obtained by fermentation

[0041] 1. Optimization of fermentation conditions of Lactobacillus casei KTx

[0042] 1. Selection of basic medium: Lactobacillus casei KTx CGMCC №.1739 was inoculated in MRS liquid medium with an inoculum of 2% (V / V), and the modified MRS liquid medium (MRS medium plus mass content of 3~4‰ corn steep liquor and 0.3~0.4‰ cysteine hydrochloride), MRS broth medium (MRS-broth liquid medium) (tryptone 5g, beef extract 10g, yeast extract 5g , glucose 10g, triammonium citrate 1g, sodium acetate 2.5g, Tween 80 0.5mL, Na 2 HPO 4 1g, MnSO 4 0.025g, MgSO 4 ·7H 2 (00.05 g, 500 mL of distilled water), after culturing at 37 ° C for 12 h, the growth amount and the amount of bile salt hydrolase were measured, and the amount of bile salt hydrolase was measured according to the following extraction and detection methods of bile salt hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com