A multi-effect leather finishing agent

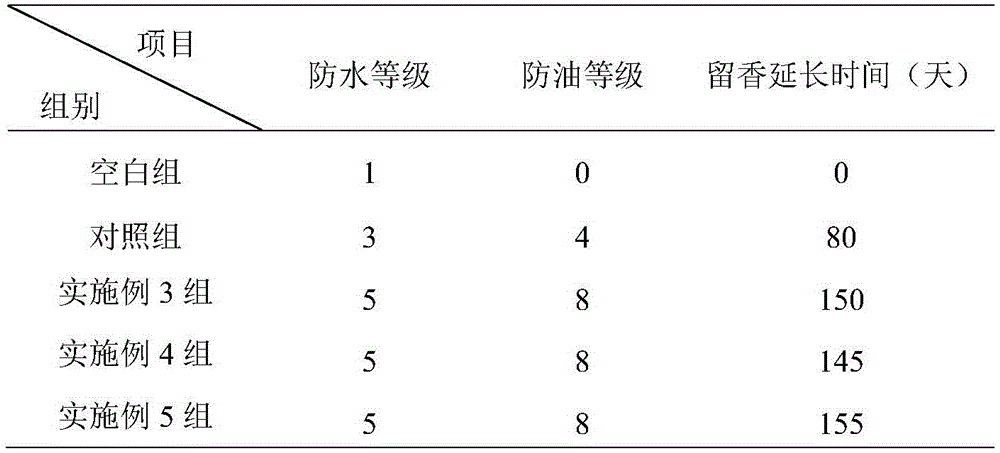

A finishing agent and leather technology, which is applied in the field of multi-effect leather finishing agents, can solve the problems that liquid essence cannot last for a long time, and can not satisfy high waterproof performance and high oil resistance at the same time, and achieves excellent performance and continuous fragrance. Long-lasting, high-oil-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] formula:

[0019] Essence 1g, nitrocellulose 2g, polyvinyl alcohol 10g, sodium carboxymethylcellulose 1g, magnesium chloride 2g, sodium lauryl sulfate 2g, ammonium citrate 3g, sodium fluoroborate 0.5g, methyl methacrylate 12g, Hydroxy silicone oil 2g, ethylene oxide 1g, diisocyanate 3g, dye 1g, ethanol 50g, water 500g.

[0020] Preparation:

[0021] (1) Add nitrocellulose, methyl methacrylate, hydroxyl silicone oil, ethylene oxide and diisocyanate into ethanol, and disperse evenly to obtain an ethanol dispersion;

[0022] (2) Add polyvinyl alcohol, sodium carboxymethylcellulose, magnesium chloride, sodium lauryl sulfate, ammonium citrate and sodium fluoroborate into water, and disperse evenly to obtain an aqueous dispersion;

[0023] (3) Mix the above ethanol dispersion and water dispersion, add essence and dye, and disperse at 1000r / min for 10 minutes to obtain the product.

Embodiment 2

[0025] formula:

[0026] Essence 1g, nitrocellulose 6g, polyvinyl alcohol 20g, sodium carboxymethylcellulose 5g, magnesium chloride 8g, sodium lauryl sulfate 6g, ammonium citrate 5g, sodium fluoroborate 0.9g, methyl methacrylate 24g, Hydroxy silicone oil 8g, ethylene oxide 5g, diisocyanate 7g, dye 5g, ethanol 70g, water 700g.

[0027] Preparation:

[0028] (1) Add nitrocellulose, methyl methacrylate, hydroxyl silicone oil, ethylene oxide and diisocyanate into ethanol, and disperse evenly to obtain an ethanol dispersion;

[0029] (2) Add polyvinyl alcohol, sodium carboxymethylcellulose, magnesium chloride, sodium lauryl sulfate, ammonium citrate and sodium fluoroborate into water, and disperse evenly to obtain an aqueous dispersion;

[0030] (3) Mix the above ethanol dispersion and water dispersion, add essence and dye, and disperse at 3000r / min for 30 minutes to obtain the product.

Embodiment 3

[0032] formula:

[0033] Essence 1g, nitrocellulose 4g, polyvinyl alcohol 15g, sodium carboxymethylcellulose 3g, magnesium chloride 5g, sodium lauryl sulfate 4g, ammonium citrate 4g, sodium fluoroborate 0.7g, methyl methacrylate 18g, Hydroxy silicone oil 5g, ethylene oxide 3g, diisocyanate 5g, dye 3g, ethanol 60g, water 600g.

[0034] Preparation:

[0035] (1) Add nitrocellulose, methyl methacrylate, hydroxyl silicone oil, ethylene oxide and diisocyanate into ethanol, and disperse evenly to obtain an ethanol dispersion;

[0036] (2) Add polyvinyl alcohol, sodium carboxymethylcellulose, magnesium chloride, sodium lauryl sulfate, ammonium citrate and sodium fluoroborate into water, and disperse evenly to obtain an aqueous dispersion;

[0037] (3) Mix the above ethanol dispersion and water dispersion, add essence and dye, and disperse at 2000r / min for 20 minutes to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com